Process for treating slag steel

A treatment process and technology for slag steel, applied in the direction of filter screen, grid, solid separation, etc., can solve the problems of low efficiency, occupying a large space, not meeting the expected requirements, etc. Reduce the requirement of path and realize the effect of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

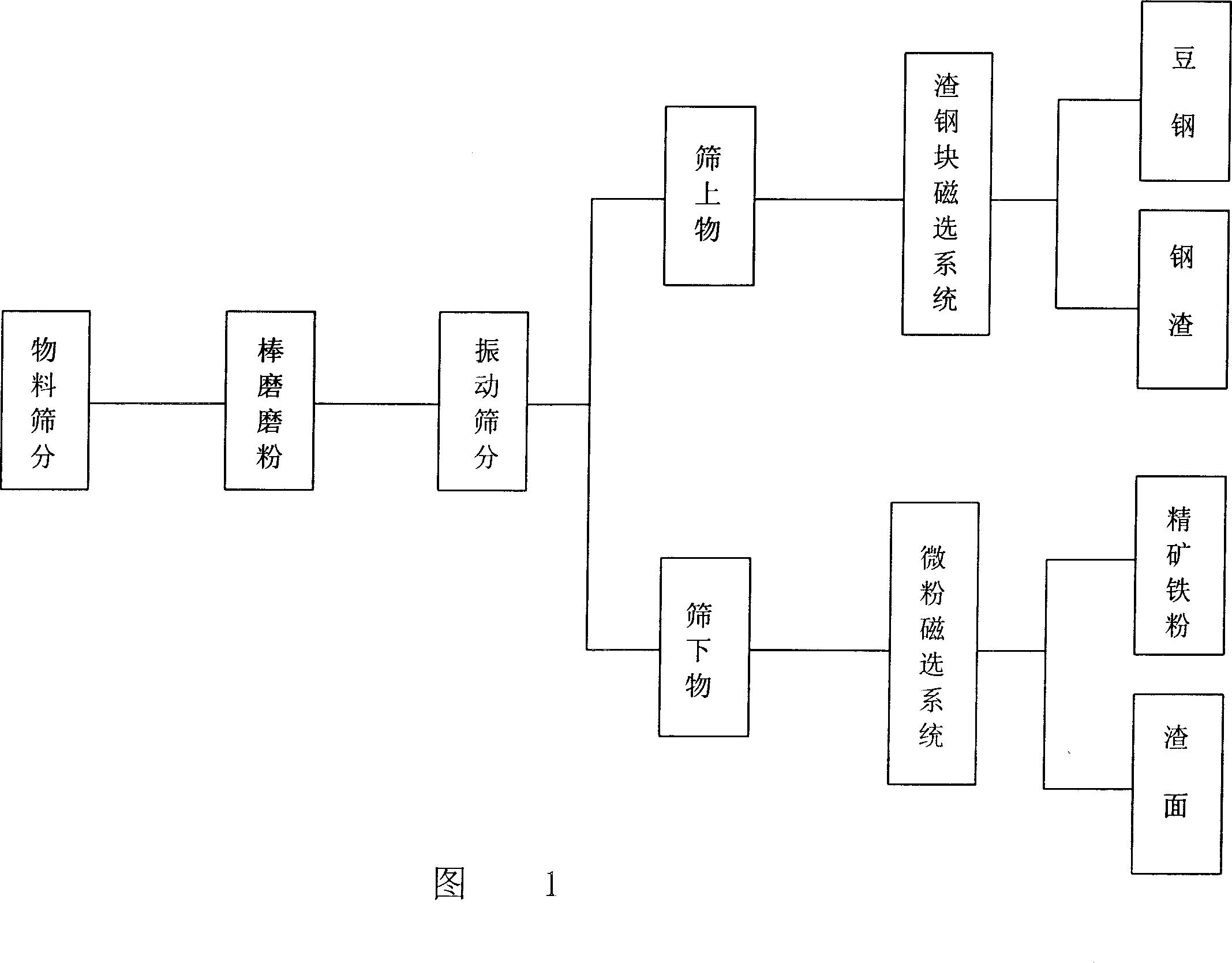

[0016] The invention absorbs the advantages of the existing slag steel processing technology, firstly sieving the material to obtain steel slag of about 300mm, and then sending the material to a rod mill for grinding through an automatic feeder, and then grinding the material. Screening is carried out in sequence, and the material on the screen is separated from soybean steel and steel slag by magnetic separation; the material under the screen is separated by magnetic separation to separate concentrate powder and slag surface.

[0017] The invention uses the peripheral discharge type rod mill for dry grinding, the hollow shaft feeds the material, the discharge end discharges the ore around the discharge end, and the discharge end is provided with a discharge grid plate, and the discharge port is large for smooth discharge; The material can enter and exit the mill smoothly, continuous feeding and continuous discharging, which can realize large-scale continuous production; the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com