Material feeding tank and material feeding system of electron beam smelting furnace, and smelting method

A feeding system and feeding trough technology, applied in the field of semiconductor manufacturing, can solve the problems of increase, material scattering, unfavorable yield, etc., and achieve the effects of reducing speed, avoiding waste, and reducing operation steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

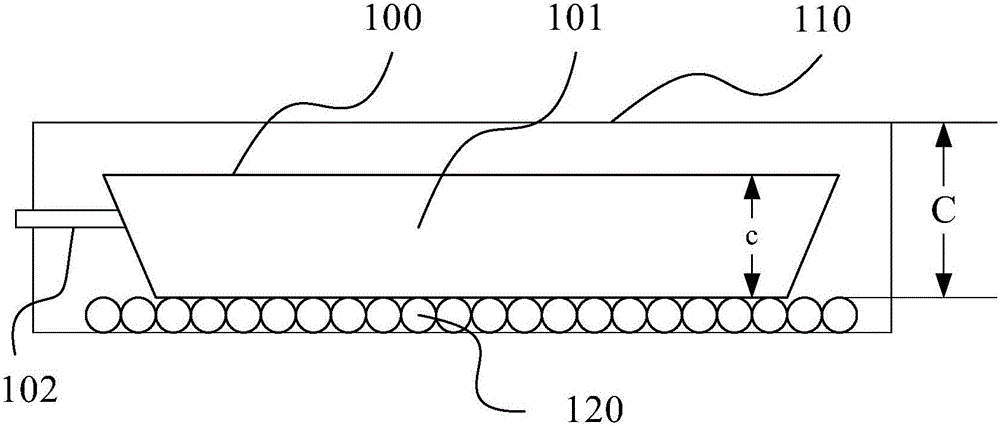

[0037] It can be seen from the background art that when the electron beam furnace in the prior art adopts bulk materials for smelting, there is a problem that a large amount of materials are scattered outside the cooling bed. Combining with the electron beam furnace bulk material feeding process in the prior art, the reasons for material scattering are analyzed:

[0038] In the electron beam melting furnace in the prior art, when bulk materials are added, the materials are often fed through the rotary feeding barrel. Collide with each other, causing a large amount of material to scatter outside the cooling bed.

[0039] In addition, during the smelting process, the material quickly falls into the cooling bed. Due to the high smelting temperature, the material heats up violently, and the gas contained in the material is released, which will also cause the molten metal liquid to splash, which again causes boring waste and reduces the yield. .

[0040] Moreover, in the process ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com