Method for preparing alumina-based nano eutectic composite micro powder by high-temperature melt aerosol method

A technology of high-temperature melt and aerosol method, which is applied in the field of high-temperature melting combined with gas atomization and quenching, which can solve the problems of low efficiency and complicated process, and achieve the effect of reducing cost, uniform particle size distribution, and suitable for large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

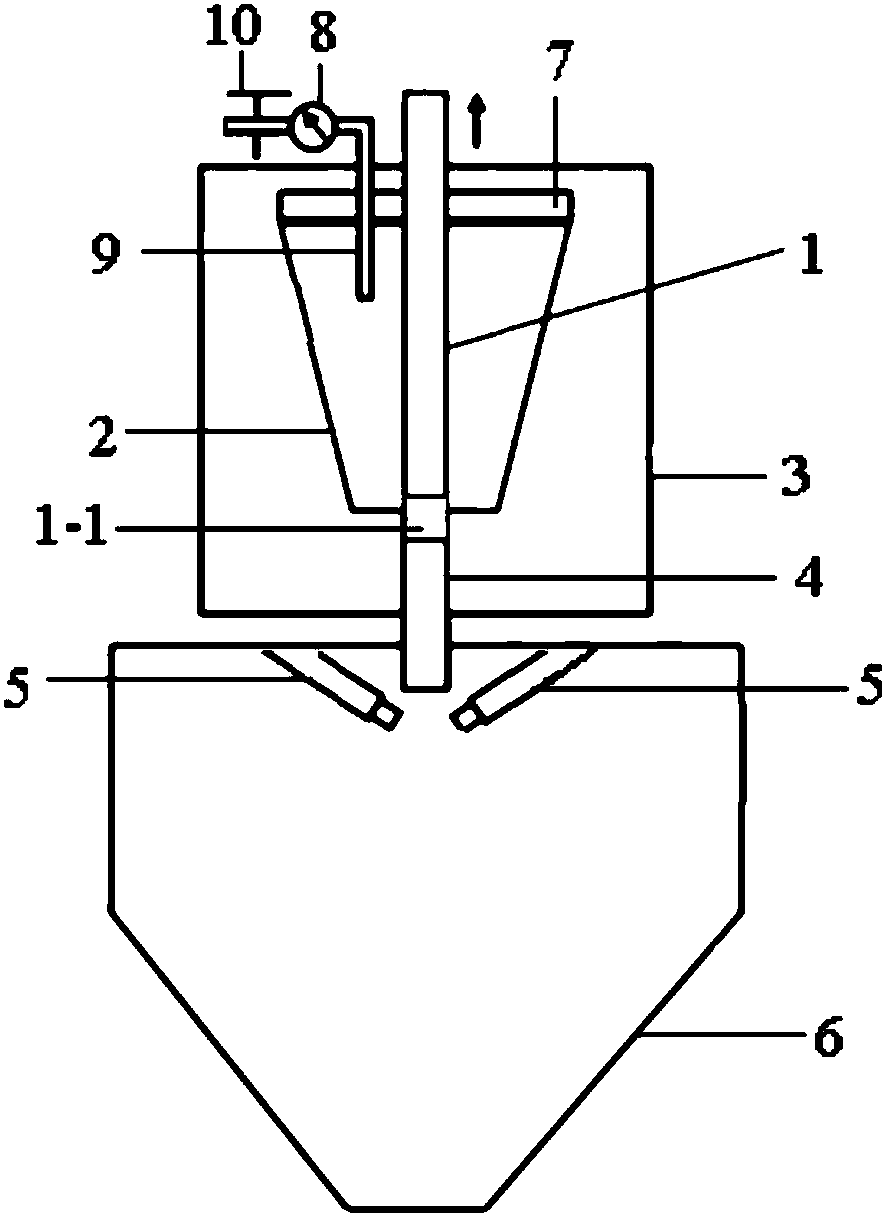

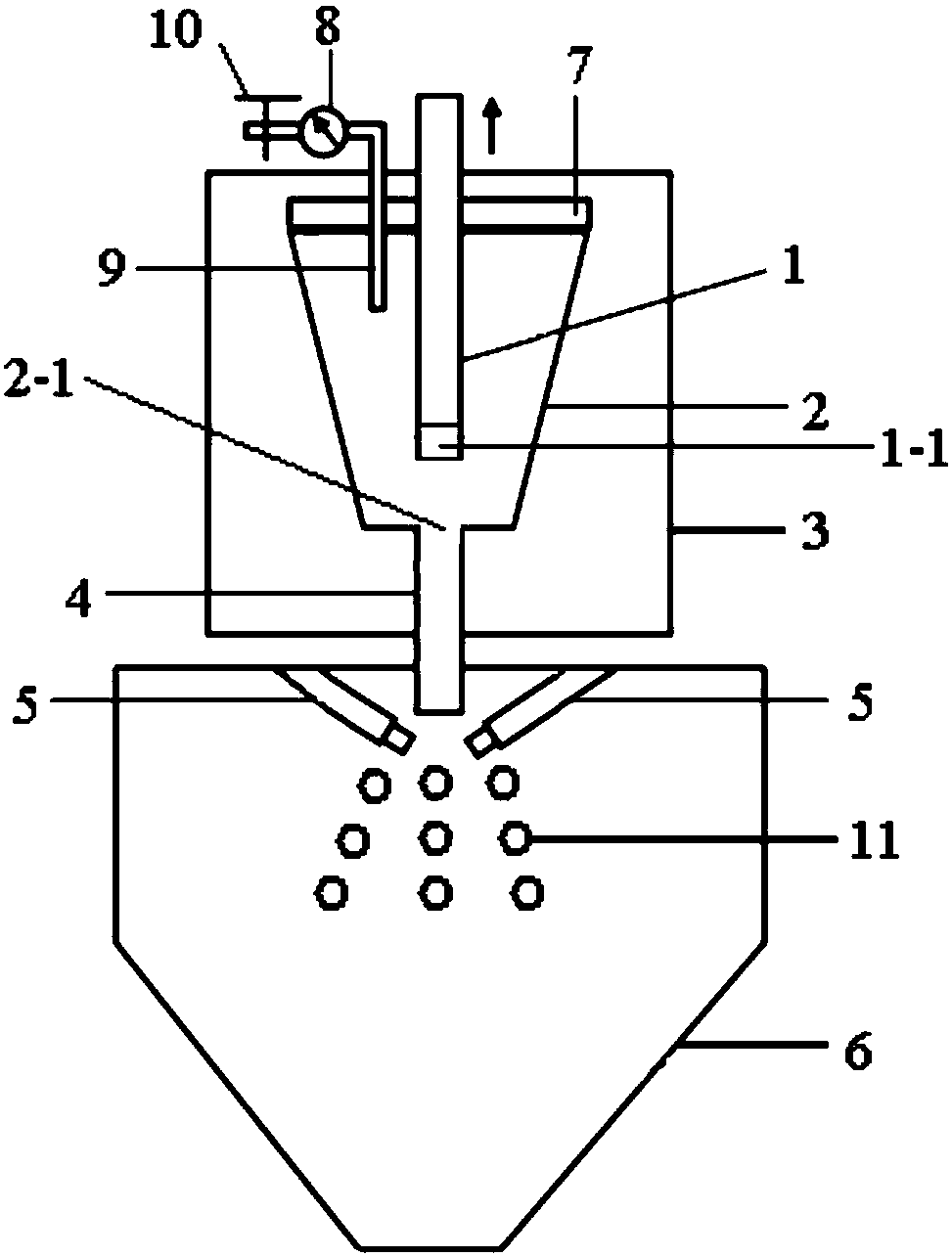

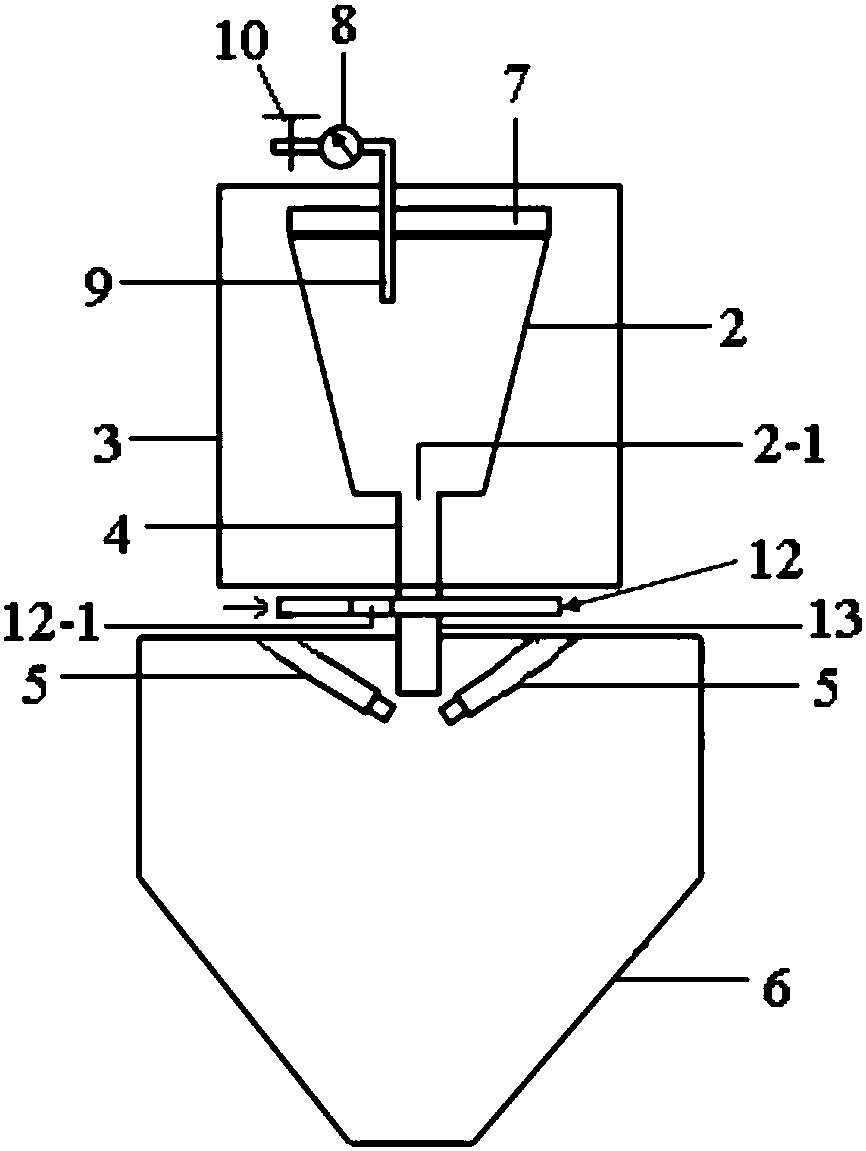

[0033] Specific embodiment one: the method for preparing alumina-based nano-eutectic micron powder by high-temperature melt aerosol method in this embodiment is implemented according to the following steps:

[0034] 1. Dry Al 2 o 3 and diluent powder, respectively, to obtain dry Al 2 o 3 and diluent powder;

[0035] Second, the dried Al 2 o 3 Mix the powder and diluent powder evenly to get a homogeneous Al 2 o 3 base powder;

[0036] 3. Mix the homogeneous Al 2 o 3 The base powder is put into the crucible, the bottom of the crucible communicates with the flow-limiting guide tube, the nozzle of the current-limiting guide tube communicates with the atomization system, the crucible is located in the high-temperature heating equipment, and the evenly heated Al 2 o 3 The base powder is melted and kept in the molten state for 10-60 minutes to obtain Al 2 o 3 base melt;

[0037] 4. Pass in inert gas to make the pressure in the crucible reach 0.2-5MPa, Al 2 o 3 The bas...

specific Embodiment approach 2

[0043] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the described diluent is ZrO 2 , Y 2 o 3 , MgO, ZnO, CeO 2 , Tb 2 o 3 、Dy 2 o 3 、Ho 2 o 3 、Er 2 o 3 、Tm 2 o 3 , Yb 2 o 3 、Gd 2 o 3 、Sm 2 o 3 One or more mixed diluents.

[0044] In this embodiment, when the diluent is a mixture, the components can be mixed in any ratio.

specific Embodiment approach 3

[0045] Specific embodiment three: the difference between this embodiment and specific embodiment two is that when the product contains zirconia, Y 2 o 3 0-20mol% of the molar content of zirconia in the product, CeO 2 0-30mol% of the molar content of zirconia in the product, MgO is 0-28mol% of the molar content of zirconia in the product, CaO is 0-33.45mol% of the molar content of zirconia in the product, TiO 2 0~44.41mol% of the molar content of zirconia in the product, Sc 2 o 3 It is 0-20 mol% of the molar content of zirconia in the product.

[0046] This embodiment combines powder mixing, high-temperature heating and melting technology and rapid cooling technology to propose a new preparation method of alumina-based nano-eutectic ceramic powder. Consider Al 2 o 3 / ZrO 2 The melting point temperature of the composite powder and the heating temperature range should be 2000-2500°C. In the preparation process, tungsten or graphite crucible is used as the container for Al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com