Halogen-free flame-retardant polyethylene functional material for aluminum-plastic composite board and preparation thereof

A technology for flame-retardant polyethylene and aluminum-plastic composite panels, which is applied in the field of halogen-free low-smoke environment-friendly flame-retardant polyethylene functional materials and their preparation, can solve the problem of slow extrusion molding speed, low yield of panels, and poor aluminum-plastic panels. meet and other problems, to achieve the effects of good flame retardant performance and thermal stability, excellent physical and mechanical properties, and easy process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

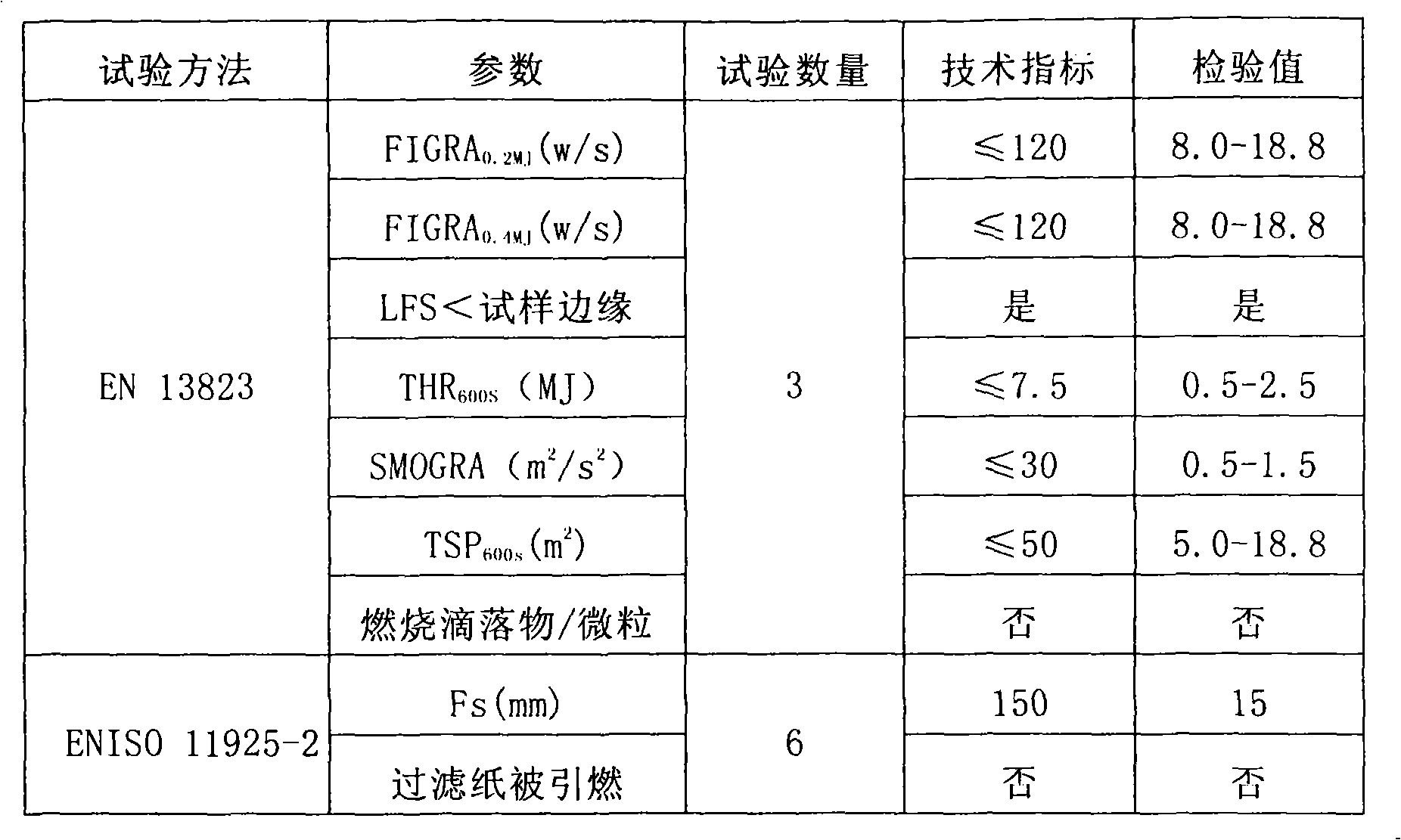

Image

Examples

Embodiment Construction

[0025] The halogen-free flame-retardant polyethylene material for the aluminum-plastic composite board of the present invention is combined with the traditional halogen-free flame-retardant core material and halogen / antimony flame-retardant polyethylene containing part or all of aluminum hydroxide and / or intumescent flame retardants. Compared with the halogen-containing flame-retardant core material, it not only does not contain halogen at all, and does not drip when melted, but also relies on the inorganic mineral brucite powder, organic silicon-based flame retardant and synergist that have been surface-treated by coupling activation, and can withstand a high temperature of 230 ° C. The endothermic decomposition reaction in the (combustion) environment produces harmless carbon dioxide gas and water for cooling and dilution, as well as metal oxides and carbon-silicon compounds that can cover the surface of the material and act as a barrier.

[0026] Due to the above-mentioned s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| tensile yield strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com