Chromium-free passivator

A chromium-free passivator and corrosion inhibitor technology, applied in the coating process of metal materials, etc., can solve problems such as uneven corrosion resistance of substrates, waste of bath solution cost, and influence on the formation of passivation film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

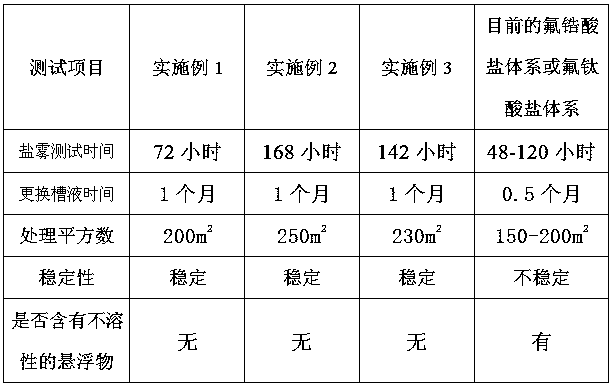

Examples

Embodiment 1

[0026] A chromium-free passivator, which is composed of the following components by weight: rare earth metal salt A: 8.5%, corrosion inhibitor: 6%, rare earth metal salt B: 3.5%, metal salt: 3.5%, water-based acrylic resin: 2.6% , Film-forming aid A: 1.2%, complexing agent: 0.55%, film-forming aid B: 0.4%, cellulose ether: 0.15% and deionized water: 73.6%.

[0027] Wherein, the rare earth metal salt A is lanthanum chloride ( ) heptahydrate.

[0028] Wherein, the corrosion inhibitor is gallic acid.

[0029] Wherein, the rare earth metal salt B is cerium chloride.

[0030] Wherein, the metal salt is cobalt nitrate.

[0031] Wherein, the film-forming aid A is fluorozirconic acid.

[0032] Wherein, the complexing agent is disodium edetate.

[0033] Wherein, the film-forming aid B is tannic acid.

[0034] Wherein, the cellulose ether is hydroxymethylcellulose.

Embodiment 2

[0036] A chromium-free passivating agent, composed of the following components by weight: rare earth metal salt A: 9%, corrosion inhibitor: 7%, rare earth metal salt B: 4%, metal salt: 4%, water-based acrylic resin: 2.8% , Film-forming aid A: 1.4%, complexing agent: 0.5%, film-forming aid B: 0.5%, cellulose ether: 0.18% and deionized water: 70.62%.

[0037] Wherein, the rare earth metal salt A is lanthanum chloride ( ) heptahydrate.

[0038] Wherein, the corrosion inhibitor is gallic acid.

[0039] Wherein, the rare earth metal salt B is cerium chloride.

[0040] Wherein, the metal salt is cobalt nitrate.

[0041] Wherein, the film-forming aid A is fluorozirconic acid.

[0042] Wherein, the complexing agent is disodium edetate.

[0043] Wherein, the film-forming aid B is tannic acid.

[0044] Wherein, the cellulose ether is hydroxymethylcellulose.

Embodiment 3

[0046] A chromium-free passivator, which consists of the following components by weight: rare earth metal salt A: 10%, corrosion inhibitor: 5.5%, rare earth metal salt B: 5%, metal salt: 4.5%, water-based acrylic resin: 3% , Film-forming aid A: 1.5%, complexing agent: 0.6%, film-forming aid B: 0.6%, cellulose ether: 0.2% and deionized water: 69.1%.

[0047] Wherein, the rare earth metal salt A is lanthanum chloride ( ) heptahydrate.

[0048] Wherein, the corrosion inhibitor is gallic acid.

[0049] Wherein, the rare earth metal salt B is cerium chloride.

[0050] Wherein, the metal salt is cobalt nitrate.

[0051] Wherein, the film-forming aid A is fluorozirconic acid.

[0052] Wherein, the complexing agent is disodium edetate.

[0053] Wherein, the film-forming aid B is tannic acid.

[0054] Wherein, the cellulose ether is hydroxymethylcellulose.

[0055] In one of the embodiments, the chromium-free passivating agent is mainly applied to the surface passivation of alumi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com