A neutral passivator for copper

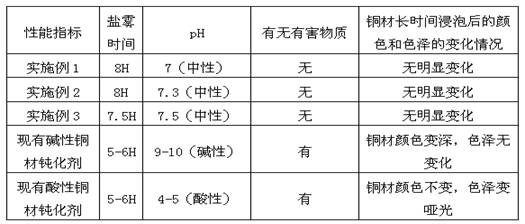

A passivating agent and neutral technology, applied in the coating process of metal materials, etc., can solve problems such as easy loss of color and brightness, pollution of environmental emissions, and impact on human health, so as to achieve good cleaning effect and improve Corrosion resistance and high cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A copper neutral passivator is composed of the following components by weight: 22% of thickener, 15% of antioxidant, 0.3% of antirust agent, 9% of organic solvent and 53.7% of deionized water.

[0034] Wherein, the thickener is polyethylene glycol 600.

[0035] Wherein, the antioxidant is a mixture of 11% by weight of mercaptobenzothiazole and 4% by weight of benzotriazole.

[0036] Wherein, the rust inhibitor is orthophosphate.

[0037] Wherein, the organic solvent is absolute ethanol.

[0038] In one of the embodiments, the method for making the copper neutral passivator into a working fluid is as follows: Step 1: Put the antioxidant and the antirust agent in the above-mentioned weight ratio into the reactor respectively, and then put the After the temperature rises to 72°C, the mixture of antioxidant and antirust agent put into the reactor is evenly stirred, the stirring speed is 100 rpm, and the stirring time is 16 minutes.

[0039] Step 2: put the organic solven...

Embodiment 2

[0046] A copper neutral passivator is composed of the following components by weight: 23% of thickener, 16% of antioxidant, 0.4% of antirust agent, 10% of organic solvent and 50.6% of deionized water.

[0047]Wherein, the thickener is a mixture of 20% polyethylene glycol 600 by weight and 3% polyethylene glycol 400 by weight.

[0048] Wherein, the antioxidant is a mixture of 10% by weight of mercaptobenzothiazole, 3% by weight of benzotriazole and 3% by weight of tolylbenzotriazole.

[0049] Wherein, the antirust agent is a mixture of 0.2% by weight of orthophosphate and 0.2% by weight of potassium salt of hydroxyethylidene diphosphonate.

[0050] Wherein, the organic solvent is a mixture of absolute ethanol with a weight ratio of 8% and isopropyl acetate with a weight ratio of 2%.

[0051] In one of the embodiments, the method for making the copper neutral passivator into a working fluid is as follows: Step 1: Put the antioxidant and the antirust agent in the above-mentioned...

Embodiment 3

[0059] A neutral passivator for copper material is composed of the following ingredients in weight ratio: 24% of thickener, 14% of antioxidant, 0.5% of antirust agent, 8.5% of organic solvent and 53% of deionized water.

[0060] Wherein, the thickener is a mixture of polyethylene glycol 600 with a weight ratio of 23% and polyethylene glycol 6000 with a weight ratio of 1%.

[0061] Wherein, the antioxidant is a mixture of 12% by weight of mercaptobenzothiazole and 2% by weight of tolylbenzotriazole.

[0062] Wherein, the rust inhibitor is 0.2% by weight of orthophosphate, 0.1% by weight of triethanolamine borate, 0.1% by weight of fatty alcohol ether phosphate potassium salt and 0.1% by weight of Mixture of potassium salt of hydroxyethylidene diphosphonate.

[0063] Wherein, the organic solvent is a mixture of 4% isopropyl acetate and 4.5% isopropyl acetate by weight.

[0064] In one of the embodiments, the method for making the copper neutral passivator into a working fluid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com