A kind of industrial device and method for continuous production of graphene powder

An industrial device, a graphene powder technology, applied in the field of nanomaterials to achieve the effects of improving preparation efficiency, avoiding environmental pollution, and avoiding energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

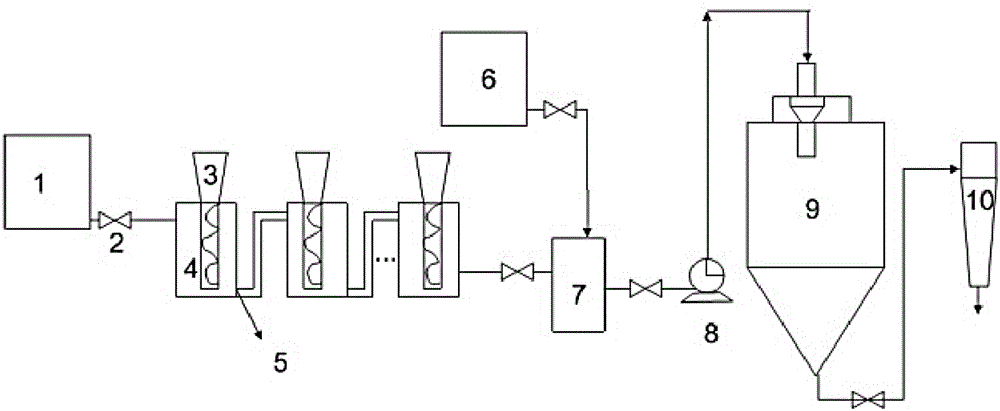

Method used

Image

Examples

Embodiment example 1

[0041] Step 1: place expanded graphite, ethanol, water, sodium dodecylbenzenesulfonate in liquid storage tank 1, sodium dodecylbenzenesulfonate content 0.01%, graphite content 1%, the proportioning of water and ethanol is 3:1, the above-mentioned substances are fully stirred to obtain a uniform graphite premixed solution, and at the same time, the microcrystalline cellulose adhesive solution is prepared in the mixing tank 6, and the concentration is 0.01%;

[0042] Step 2: Control the flow valve, flow the above-mentioned premixed liquid into the microwave reactor 4 through the pipeline at a speed of 100L / h, turn on 8 concentrated-energy ultrasonic probes to participate in the work, and use the same frequency method to peel off the graphite, the frequency is 20kH at a low frequency 1. Adjust the output power of the microwave reactor to 200W, and obtain the graphene dispersion in the liquid storage tank 7;

[0043] Step 3: Control the flow rate of the flow valve of the mixing ta...

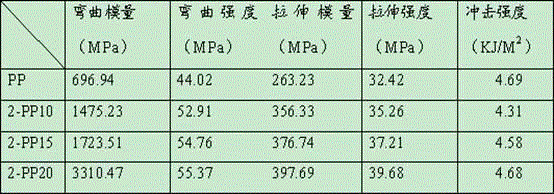

Embodiment example 2

[0050] Step 1: Expanded graphite, water, ethylene glycol, and sodium citrate are placed in liquid storage tank 1, the content of sodium citrate is 0.01%, the content of graphite is 1%, and the ratio of water and ethylene glycol is 4:1. The material is fully stirred to obtain a uniform graphite premixed solution, and a carboxymethyl cellulose adhesive solution is prepared in the mixing tank 6 at the same time, and the concentration is 0.01%;

[0051] Step 2: Control the flow valve, flow the above-mentioned premixed liquid into the microwave reactor through the pipeline at a speed of 150L / h, turn on 8 concentrated ultrasonic probes to participate in the work, and use the frequency mixing method to peel off the graphite, the frequency is 20kH, 30kH, 40kH, 50kH, 20kH, 30kH, 40kH, 50kH, adjust the output power of the microwave reactor to be 300W, and obtain the graphene dispersion in the liquid storage tank 7;

[0052] Step 3: Control the flow rate of the flow valve of the mixing t...

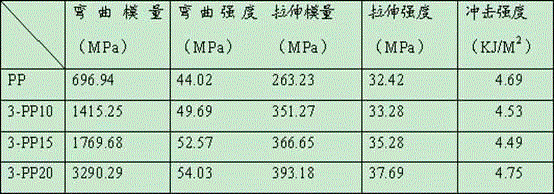

Embodiment example 3

[0059] Step 1: Put expanded graphite, water, N-methylpyrrolidone, and sodium lauryl sulfate in liquid storage tank 1, the content of sodium lauryl sulfate is 0.01%, the content of graphite is 2%, water and N-methylpyrrolidone The proportioning ratio is 4:1, the above-mentioned substances are fully stirred to obtain a uniform graphite premixed solution, and the polyacrylic resin adhesive solution is prepared in the mixing tank 6 at the same time, and the concentration is 0.02%;

[0060] Step 2: Control the flow valve, flow the above-mentioned premixed liquid into the microwave reactor through the pipeline at a speed of 200L / h, turn on 8 concentrated ultrasonic probes to participate in the work, and use the frequency mixing method to peel off the graphite, the frequency is 20kH, 30kH, 40kH, 20kH, 30kH, 40kH, 20kH, 20kH, adjust the output power of the microwave reactor to be 250W, and obtain the graphene dispersion in the liquid storage tank 7;

[0061] Step 3: Control the flow r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com