Fiber/long-carbon-chain nylon in-situ composite material and preparation method

An in-situ composite material and long carbon chain technology, which is applied in the field of fiber composite materials to achieve the effects of improved interfacial adhesion, excellent strength and improved dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

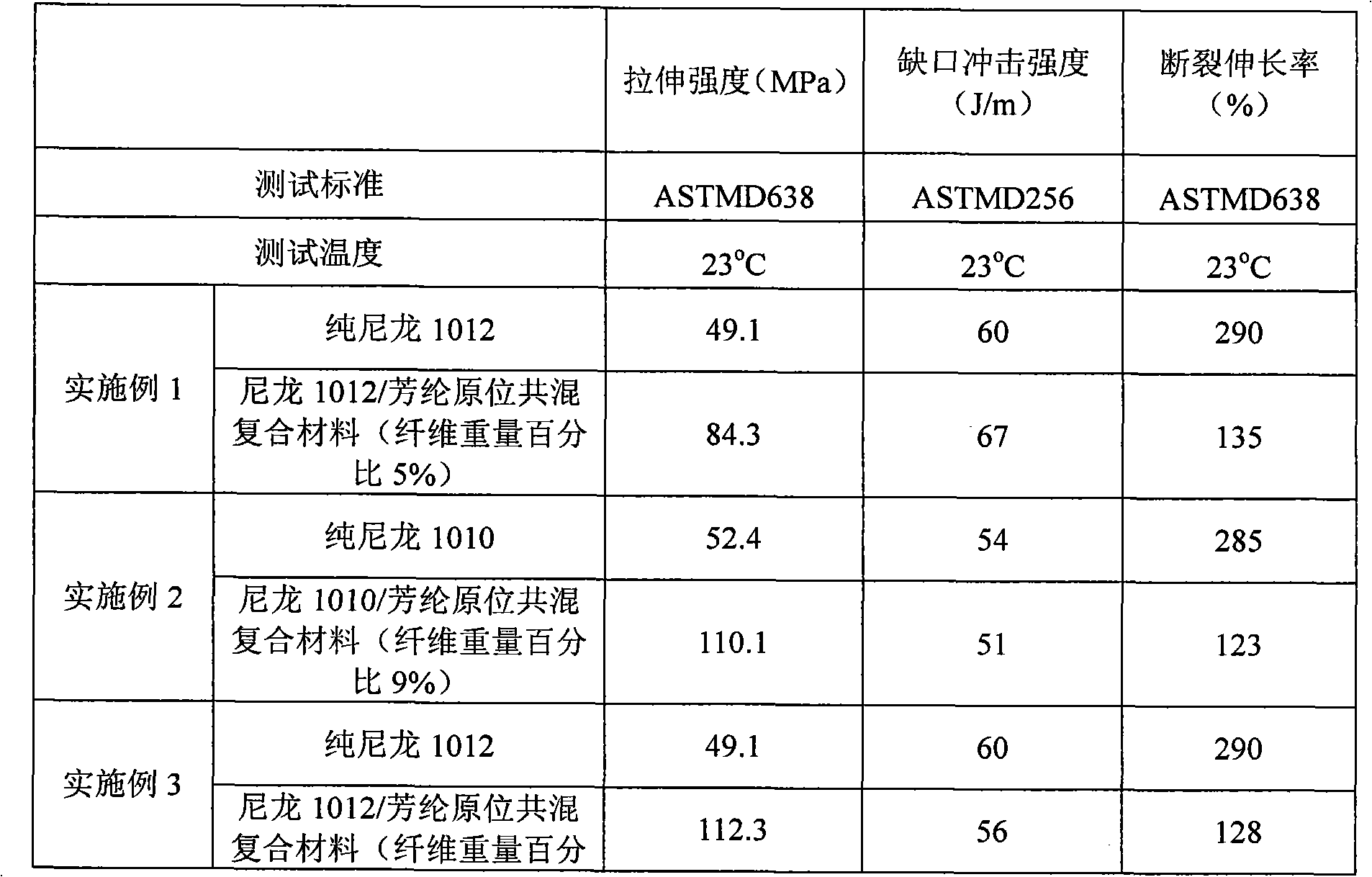

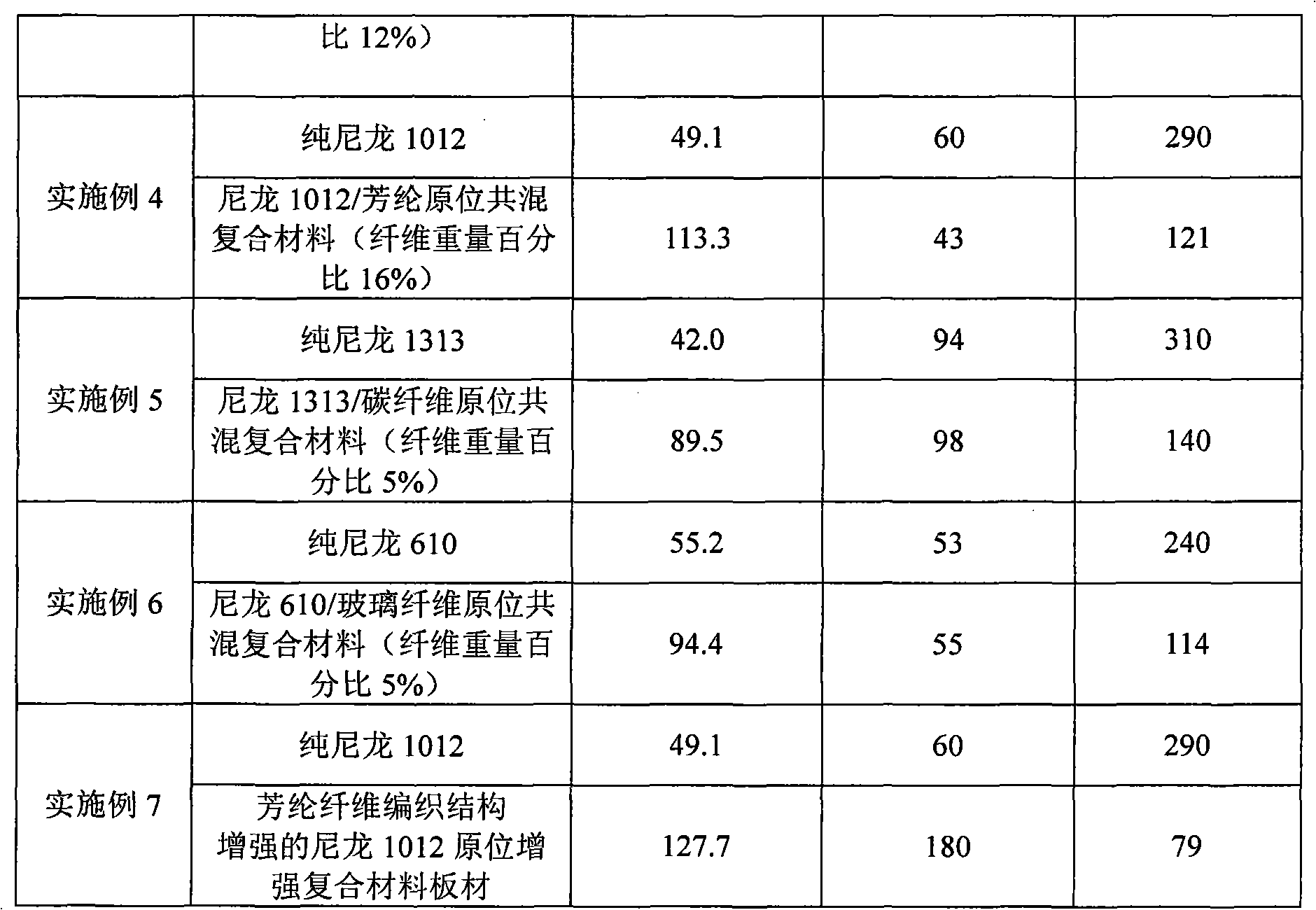

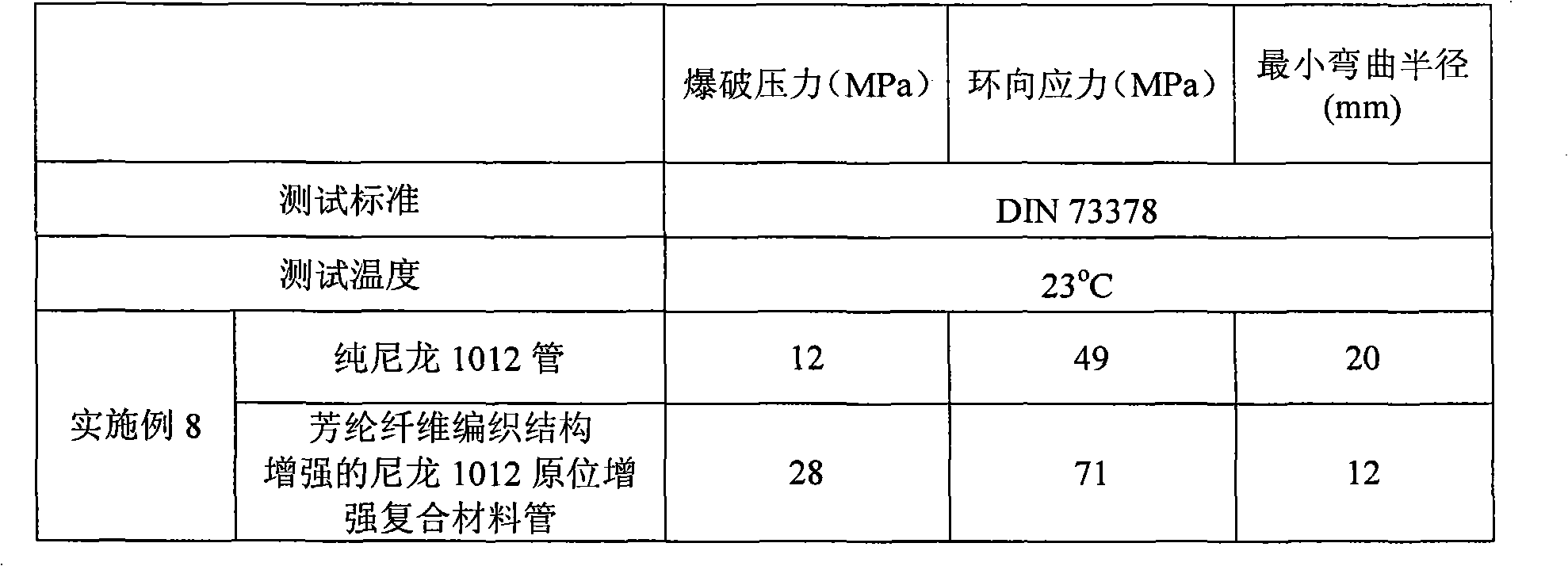

Examples

Embodiment 1

[0041] 1. Preparation of nylon 1012 salt: weigh 1Kg of dodecanedibasic acid, 4Kg of 99.5% ethanol, and mix to obtain an ethanol solution of dodecanedibasic acid; weigh 0.96Kg of decanediamine, 1Kg of 99.9% ethanol, and mix to prepare Obtain the ethanol solution of decanediamine; heat the obtained ethanol solution of dodecanedibasic acid to 35°C, and then add it dropwise into the stirred reactor containing the ethanol solution of decanediamine, and the dropping time is 20 minutes Put it into an ice-water bath after standing still for 15 minutes, collect the precipitated suspended matter, wash with ethanol to obtain nylon 1012 salt, and dry it in a vacuum oven for 48 hours;

[0042] 2. Fiber pretreatment: take aramid staple fiber (produced in Japan, model 968) with a length of 1 mm and a diameter of 13 μm, soak it in acetone for 3 hours, take it out and dry it in vacuum at 80°C for 12 hours;

[0043] 3. Polycondensation reaction: 95 parts by weight of nylon 1012 salt and 5 parts...

Embodiment 2

[0045] 1. Preparation of nylon 1010 salt: Weigh 1Kg of sebacic acid and 4Kg of 99.9% ethanol, and mix them to obtain an ethanol solution of sebacic acid. Weigh 0.96Kg of decanediamine, 1Kg of 99.9% ethanol, and mix to obtain an ethanol solution of decanediamine; heat the obtained ethanol solution of sebacic acid to 35° C., and then add it dropwise to a stirred tank containing decanediamine ethanol In the reactor of the solution, the dripping time is 20 minutes; after standing for 15 minutes, put it into an ice-water bath, collect the precipitated suspended matter, obtain nylon 1010 salt, and dry it in a vacuum oven for 48 hours;

[0046] 2. Fiber pretreatment: take aramid staple fiber (produced in Japan, model 968) with a length of 1 mm and a diameter of 13 μm, soak it in acetone for 3 hours, take it out and dry it in vacuum at 80°C for 12 hours;

[0047] 3. Polycondensation reaction: 91 parts by weight of nylon 1010 salt and 9 parts by weight of aramid fiber were mixed in a h...

Embodiment 3

[0049] 1. Preparation of nylon 1012 salt: Weigh 1 Kg of dodecanedibasic acid and 4 Kg of 99.9% ethanol, and mix them to obtain an ethanol solution of dodecanedibasic acid. Weigh 0.96Kg of decanediamine and 1Kg of 99.9% ethanol, and mix them to obtain an ethanol solution of decanediamine. Heat the ethanol solution of dodecanedibasic acid to 35°C, then add it dropwise into a stirred reactor containing ethanol solution of decanediamine, and the adding time is 20 minutes; after standing for 15 minutes, put it in ice In a water bath, the precipitated suspended matter was collected to obtain nylon 1012 salt, and dried in a vacuum oven for 48 hours;

[0050] 2. Fiber pretreatment: take aramid staple fiber (produced in Japan, model 968) with a length of 1 mm and a diameter of 13 μm, soak it in acetone for 3 hours, take it out and dry it in vacuum at 80°C for 12 hours;

[0051] 3. Polycondensation reaction: 88 parts by weight of nylon 1012 salt and 12 parts by weight of aramid fiber w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com