Template-free synthesis method of eggshell-shaped silicon dioxide nanomaterial

A technology of silicon dioxide and nanomaterials, applied in the direction of silicon dioxide and silicon oxide, which can solve problems such as low efficiency and cumbersome steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A template-free synthesis method of eggshell-shaped silica nanomaterials, the synthesis steps are as follows:

[0026] The first step: the HSiCl 3 and tri-n-propylamine in a molar ratio of 1:2 (volumes less than 2ml respectively) were added to 20ml of dichloromethane.

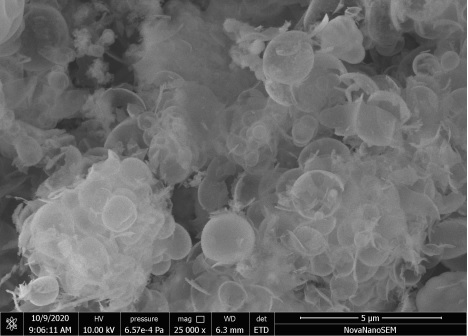

[0027] Step 2: After stirring at room temperature for 5 hours, spin the yellow solution to dryness, place the remaining yellow viscous substance in a crucible, and calcinate it in a muffle furnace at 700°C for 3 hours to obtain eggshell-shaped hollow nano-SiO 2 .

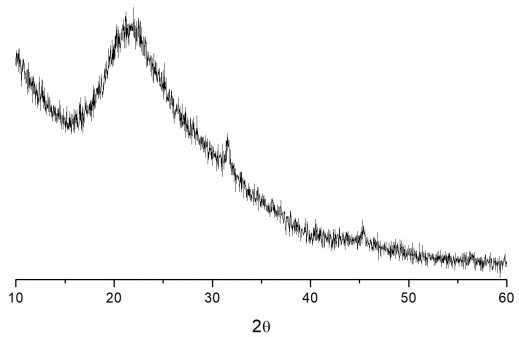

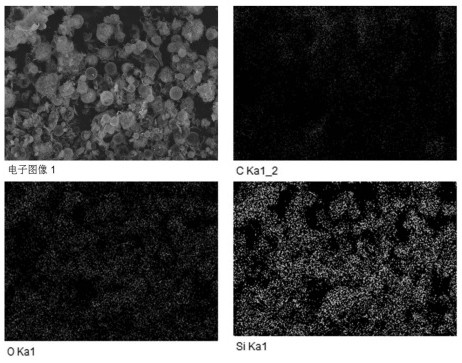

[0028] Such as figure 2 The obtained eggshell SiO 2 XRD pattern, it can be seen that the product is relatively pure SiO 2 ,Depend on image 3 The elemental distribution diagram shown can further see that the elemental composition of the product is Si and O.

Embodiment 2

[0030] A template-free synthesis method of eggshell-shaped silica nanomaterials, the synthesis steps are as follows:

[0031] Step 1: Si 2 Cl 6 and tri-n-propylamine were added to 20 ml of dichloromethane at a molar ratio of 1:2 (the volumes were less than 2 ml).

[0032] Step 2: After stirring at room temperature for 5 hours, the stirring speed is 500-1000r / min, and the yellow solution is spin-dried at a spin-drying temperature of 20-70°C. Calcined in a furnace at 700°C for 3 hours to obtain eggshell-shaped hollow nano-SiO 2 .

Embodiment 3

[0034] A template-free synthesis method of eggshell-shaped silica nanomaterials, the synthesis steps are as follows:

[0035] The first step: the HSiCl 3 and tri-n-propylamine in a molar ratio of 1:2 (volumes less than 2ml respectively) were added to 20 ml of an oxygen-free organic solvent, such as benzene, toluene, chloroform or acetonitrile.

[0036] Step 2: After stirring at room temperature for 5 hours, the stirring speed is 500-1000r / min, and the yellow solution is spin-dried at a spin-drying temperature of 20-70°C. Calcined in a furnace at 700°C for 3 hours to obtain eggshell-shaped hollow nano-SiO 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com