A method to improve oil production efficiency and carbon fixation rate of microalgae

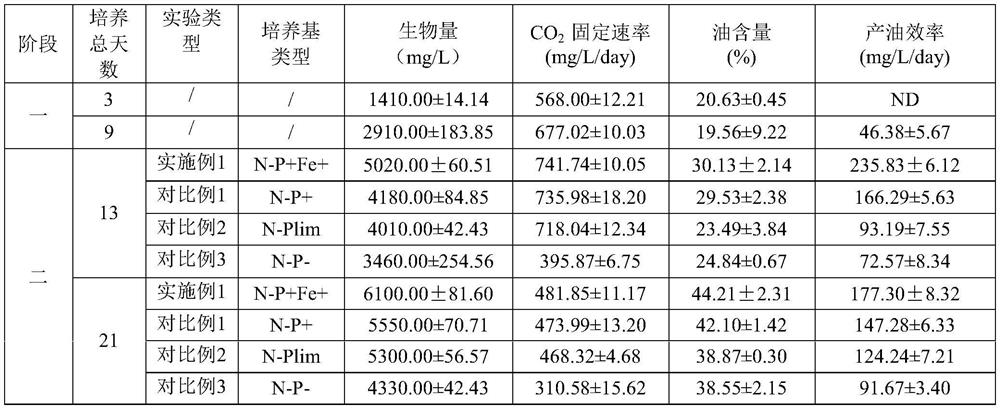

A microalgae and high-efficiency technology, which is applied in the field of microalgae biotechnology and carbon emission reduction, can solve the problems that high oil content and high oil production rate are difficult to obtain at the same time, lipid production rate cannot be effectively improved, and lack of stimulation to increase lipid content and other problems , to achieve the effects of improving carbon sequestration efficiency, solving biomass yield and oil production efficiency, and increasing oil content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

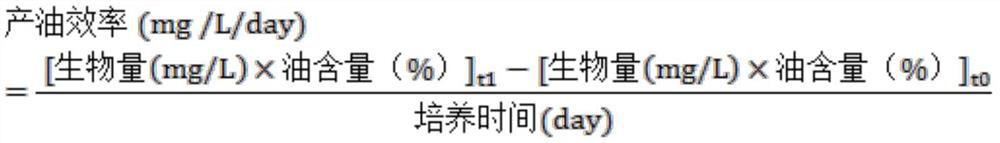

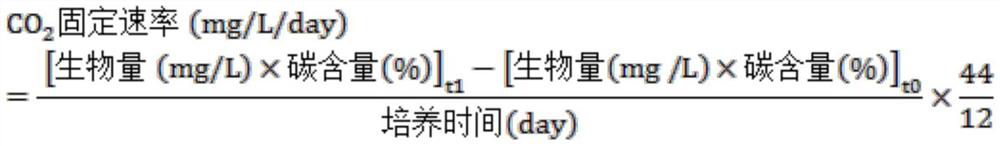

Method used

Image

Examples

Embodiment 1

[0025] (1) Sterilize the BG11 medium at 121°C for 30 minutes. After the medium is cooled to room temperature, divide it into 600mL round-bottomed glass bottles, inoculate microalgae, and carry out the first stage of cultivation;

[0026] BG11 medium consists of the following components: NaNO 3 1500mg / L, K 2 HPO 4 ·3H 2 O 40mg / L, MgSO 4 ·7H 2 O75mg / L, Na 2 CO 3 20mg / L, CaCl 2 27mg / L, citric acid monohydrate 6mg / L, ferric ammonium citrate 6mg / L, Na 2 EDTA1mg / L, trace element A 5 Solution 1mL, where, A 5 Consists of: H 3 BO 3 2.86mg / L, MnCl 2 4H 2 O1.81mg / L, ZnSO 4 ·7H 2 O 0.222mg / L, CuSO 4 ·5H 2 O 0.079mg / L, CoCl 2 ·6H 2 O 0.050mg / L, Na 2 MoO 4 2H 2 O 0.39mg / L;

[0027] In the present embodiment, the microalgae algae are passed through 60 CO-γ-ray mutagenesis and can tolerate a volume fraction of 60% CO 2 of Chlorella pyrenoidosa, this microalgae undergoes a high-concentration gradient CO 2 For domestication, the concentration of inoculated microalg...

Embodiment 2

[0032] In this embodiment, the microalgae species have not passed through 60 CO-γ-ray mutagenesis, but after high concentration gradient CO 2 For domesticated Chlorella pyrenoidosa, the concentration of inoculated microalgae is 450mg / L.

[0033] Other steps in this embodiment are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com