A kind of preparation method of cyclodextrin microsphere

A cyclodextrin and microsphere technology, used in chemical instruments and methods, other chemical processes, water/sludge/sewage treatment, etc. The post-processing is cumbersome and other problems, to achieve the effect of good monodispersity, high recycling rate, and convenient separation and recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Dissolve 2g of β-cyclodextrin in 4mL of NaOH solution with a mass fraction of 20%, alkalinize with stirring at 40°C for 0.5h, and then add 2.4g of epichlorohydrin for pre-crosslinking for 2.5h. to stir. After the reaction, a liquid and viscous pre-crosslinked product is obtained.

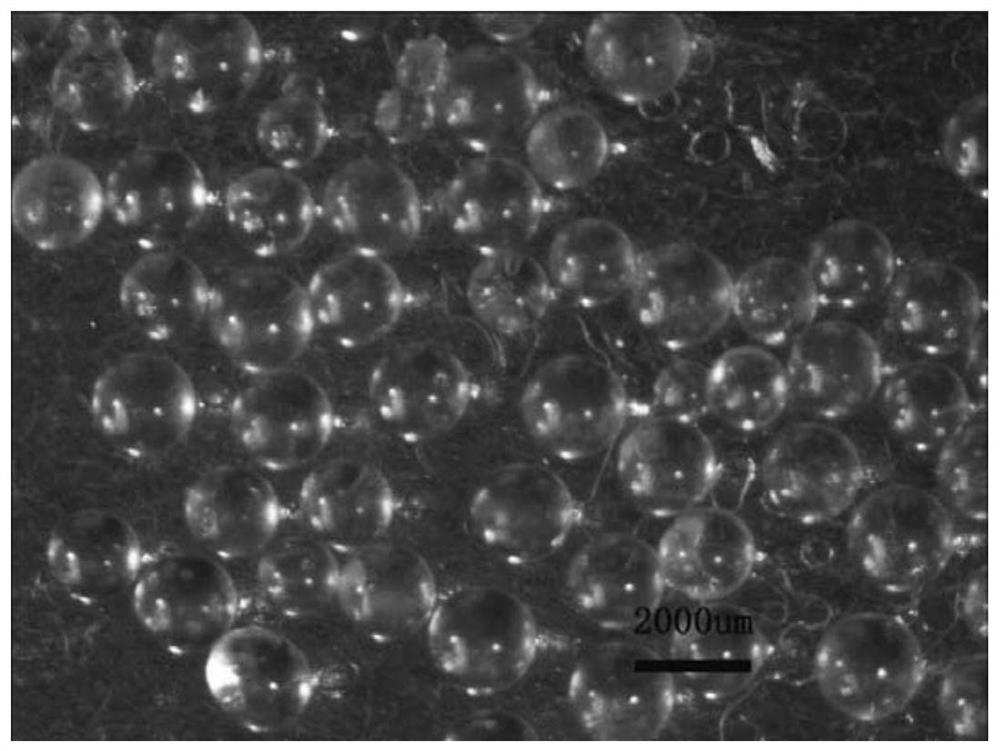

[0033] (2) Mix the pre-crosslinked product with 25# transformer oil at a volume ratio of 1:2, and stir at 100r / min at 40°C until the pre-crosslinked product exists completely in the form of microspheres.

[0034] (3) The product after the reaction is left to stand for about 10min, and after the microsphere particles in the oil phase are completely precipitated, the upper oil phase is sucked out and recovered with a straw, and the microsphere particles are rinsed with distilled water and then soaked in absolute ethanol for 24h. Remove the residual oil phase inside the microsphere particles.

[0035] (4) Dry the microsphere particles in a vacuum oven at 50°C to constant weight to obtain β...

Embodiment 2

[0037] (1) Dissolve 2g of β-cyclodextrin in 4mL of NaOH solution with a mass fraction of 20%, alkalinize with stirring at 40°C for 0.5h, then add 2.4g of glutaraldehyde for pre-crosslinking for 1h, supplemented with 100~ Stir at 300r / min. After the reaction, a liquid and viscous pre-crosslinked product is obtained.

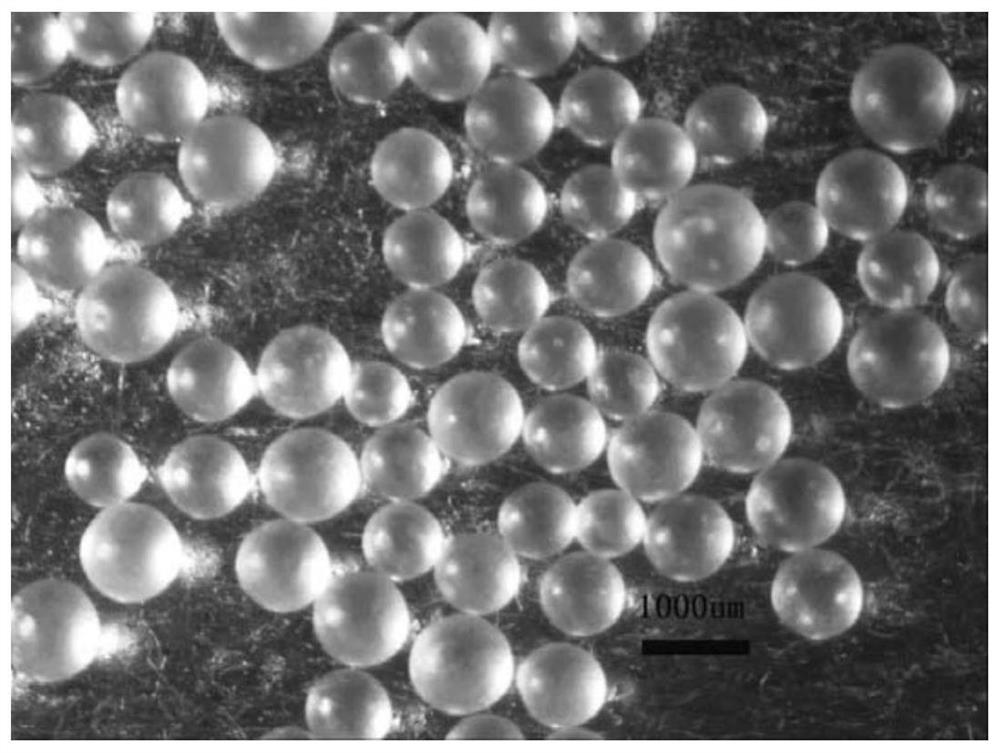

[0038] (2) Mix the pre-crosslinked product and lubricating oil at a volume ratio of 1:3, and stir at 300r / min at 40°C until the pre-crosslinked product exists completely in the form of microspheres.

[0039] (3) The product after the reaction is left to stand for about 10min, and after the microsphere particles in the oil phase are completely precipitated, the upper oil phase is sucked out and recovered with a straw, and the microsphere particles are rinsed with distilled water and then soaked in absolute ethanol for 24h. Remove the residual oil phase inside the microsphere particles.

[0040] (4) Dry the microsphere particles in a vacuum oven at 50°C to constant...

Embodiment 3~5

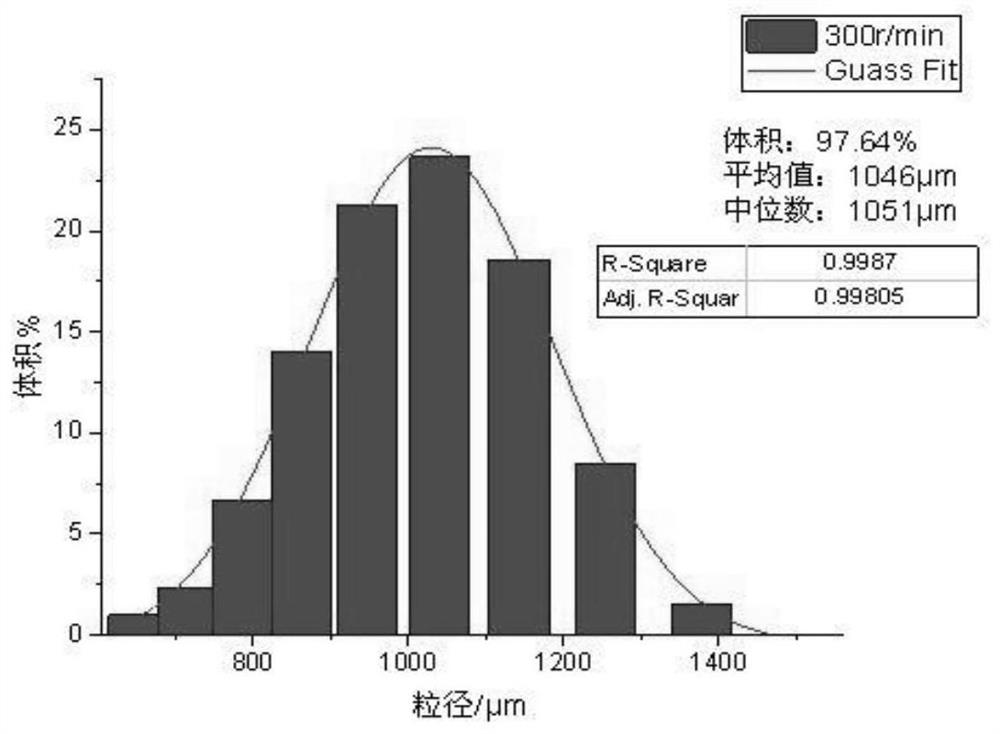

[0042] Using almost the same treatment as in Example 1, only the stirring rate in the pre-crosslinked product / oil phase reaction process (step (2)) is adjusted: the stirring rate is adjusted to 300, 700 and 1000r / min respectively, as an implementation The processing of examples 3 to 5 (the stirring rate corresponding to embodiment 3 is 300r / min, the corresponding 700r / min of embodiment 4, and the corresponding 1000r / min of embodiment 5).

[0043] control treatment

[0044] On the basis of the treatment in Example 3, the simple oil phase used in step (2) was changed to the oil phase added with an emulsifier (equivalent to the conventional inverse emulsion polymerization method), as control treatment 1. Wherein, the emulsifier is a mixture of Span-80 and Tween-20, m(Span-80):m(Tween-20)=3:1, and the mass ratio of the emulsifier to the oil phase is 1:30. Control treatment 2 of Example 4 and control treatment 3 of Example 5 were set in the same manner.

[0045] The microspheres ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com