A kind of electrochemical preparation method of ternary cathode material

A positive electrode material, electrochemical technology, applied in the field of electrochemical preparation of ternary positive electrode materials, can solve the problems of difficult control of purity, high price, environmental pollution, etc., achieve uniform product components, good consistency, and reduce environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

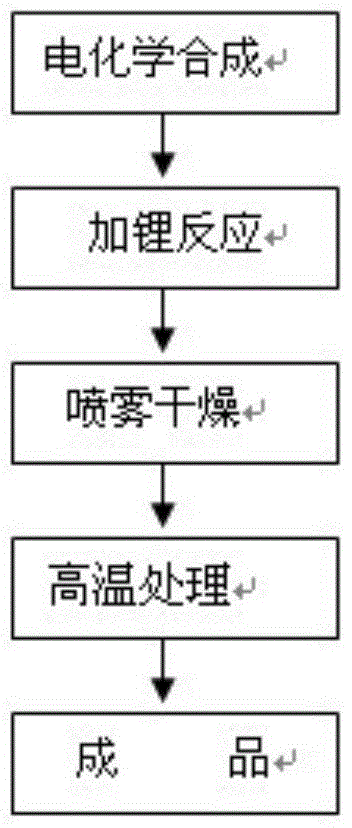

Method used

Image

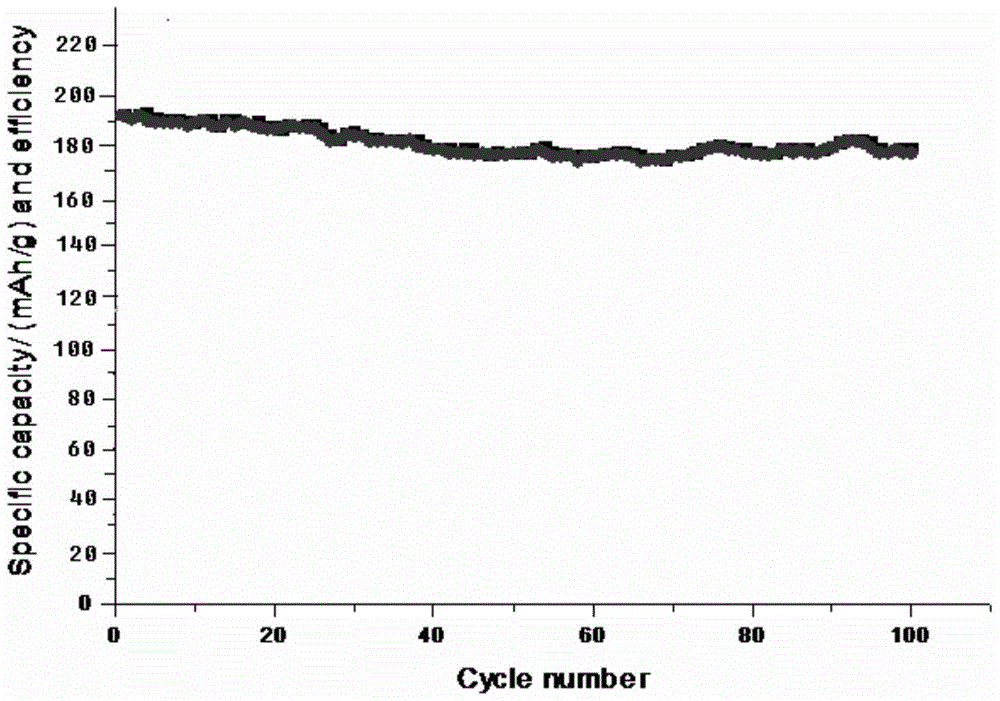

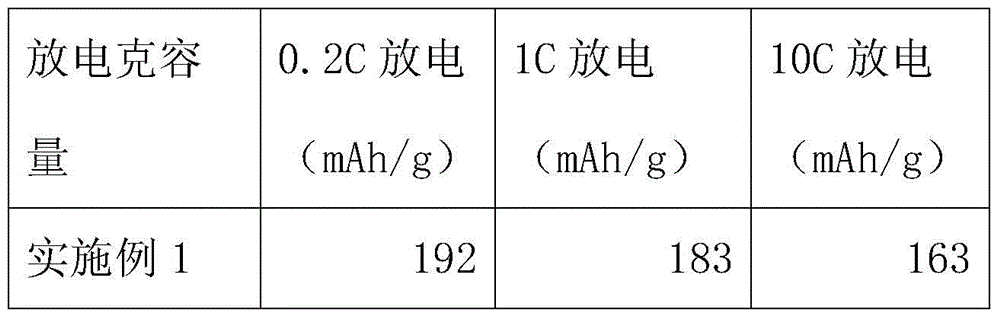

Examples

Embodiment 1

[0017] A preparation method of a ternary positive electrode material, comprising the following steps:

[0018] (1) Prepare 100L 1.0mol / L acetic acid and citric acid electrolytes, which contain 0.8mol / L acetic acid and 0.2mol / L citric acid, use pure metal nickel, cobalt, and manganese as anodes, and use inert electrode titanium as the cathode , control the current 3A for electrolysis, stop the electrolysis when the electrolysis power reaches 160F (Faraday, 1F=26.8Ah), and obtain a solution with a concentration of 0.8mol / L nickel, cobalt, and manganese ions.

[0019] (2) Mix the nickel, cobalt, and manganese ion solutions at a molar ratio of nickel ions: cobalt ions: manganese ions = 0.5:0.2:0.3, and slowly add 1.0mol / L lithium hydroxide dropwise to the continuously stirred reactor , according to the molar ratio lithium ion: (nickel ion + cobalt ion + manganese ion) = 1.1:1 molar ratio measurement, the whole process is controlled at a temperature of about 50 ° C and stirred for ...

Embodiment 2

[0022] A preparation method of a ternary positive electrode material, comprising the following steps:

[0023] (1) Prepare 100L 2.0mol / L acetic acid and citric acid electrolytes, which contain 1.2mol / L acetic acid and 0.8mol / L citric acid, use pure metal nickel, cobalt, and manganese as anodes, and use inert electrode stainless steel as cathodes , control current 6A electrolysis, stop electrolysis when the electrolysis power reaches 240F, and obtain nickel, cobalt and manganese ion solutions with a concentration of 1.2mol / L.

[0024] (2), nickel, cobalt, manganese ion solution are mixed by the molar ratio of nickel ion: cobalt ion: manganese ion=1 / 3:1 / 3:1 / 3, slowly drop the lithium hydroxide of 1.0mol / L to In a continuously stirred reactor, the molar ratio of lithium ions: (nickel ions + cobalt ions + manganese ions) = 1.2:1 is measured, the temperature is controlled at about 60°C for 18 hours, and the pH is controlled at 8.5 to obtain a stream Phase-changing suspension.

[...

Embodiment 3

[0027] A preparation method of a ternary positive electrode material, comprising the following steps:

[0028] (1) Prepare 100L 2.6mol / L acetic acid and citric acid electrolytes, which contain 1.6mol / L acetic acid and 1.0mol / L citric acid, use pure metal nickel, cobalt, and manganese as anodes, and use inert electrode stainless steel as cathodes , control current 6A electrolysis, electrolysis electricity to 320F, stop electrolysis, the concentration is 1.6mol / L nickel, cobalt, manganese ion solution.

[0029] (2), nickel, cobalt, manganese ion solution are mixed by the molar ratio of nickel ion: cobalt ion: manganese ion=1 / 3:1 / 3:1 / 3, slowly drop the lithium hydroxide of 1.0mol / L to In the continuously stirred reactor, measure according to the molar ratio of lithium ions: (nickel ions + cobalt ions + manganese ions) = 1.15:1. During the whole process, the temperature is controlled at about 50°C and the reaction is stirred for 18 hours. The pH is controlled at 8 to obtain a rheo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com