Method and production system for producing reagent hydrochloric acid by using tail gas of Mannheim furnace

A Mannheim furnace, reagent hydrochloric acid technology, applied in chemical instruments and methods, halogen/halogen acid, chlorine/hydrogen chloride purification, etc., can solve the problems of small production scale, low output rate, high energy consumption, and achieve output The effect of high rate, reduced energy consumption and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

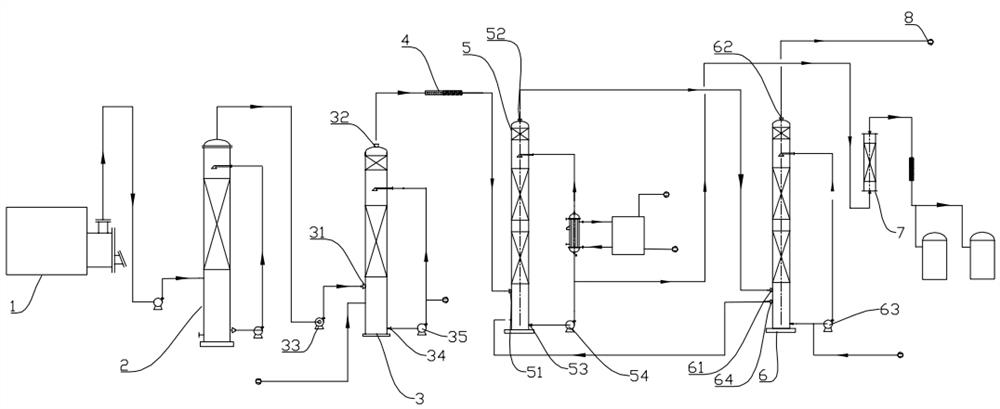

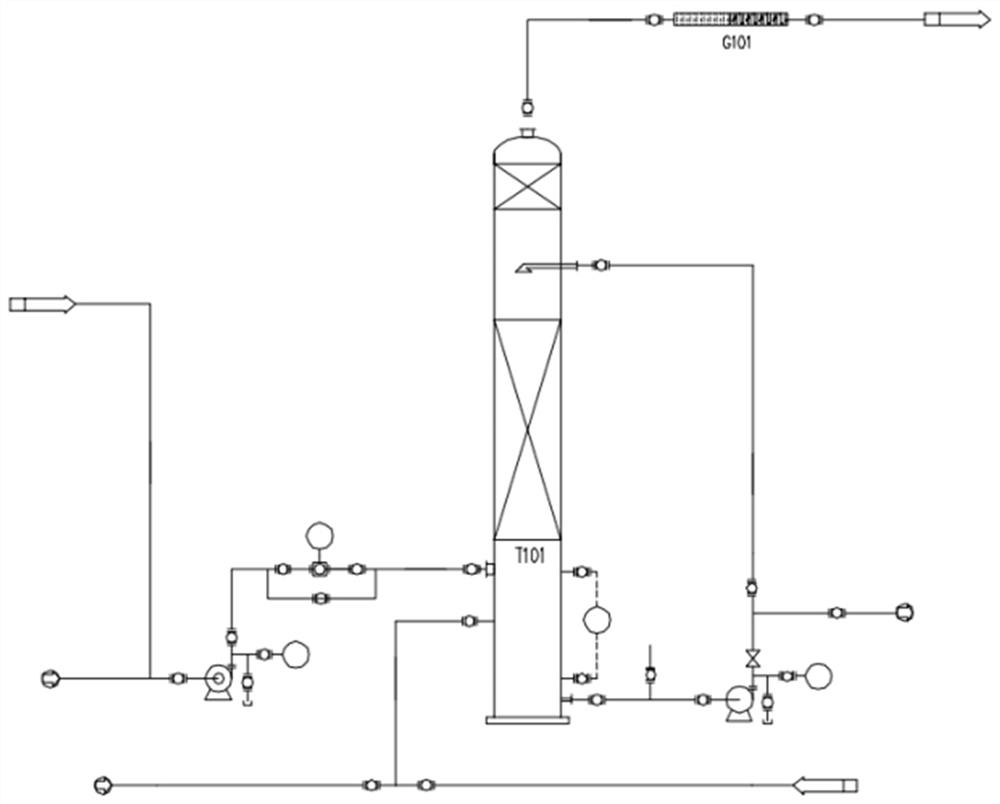

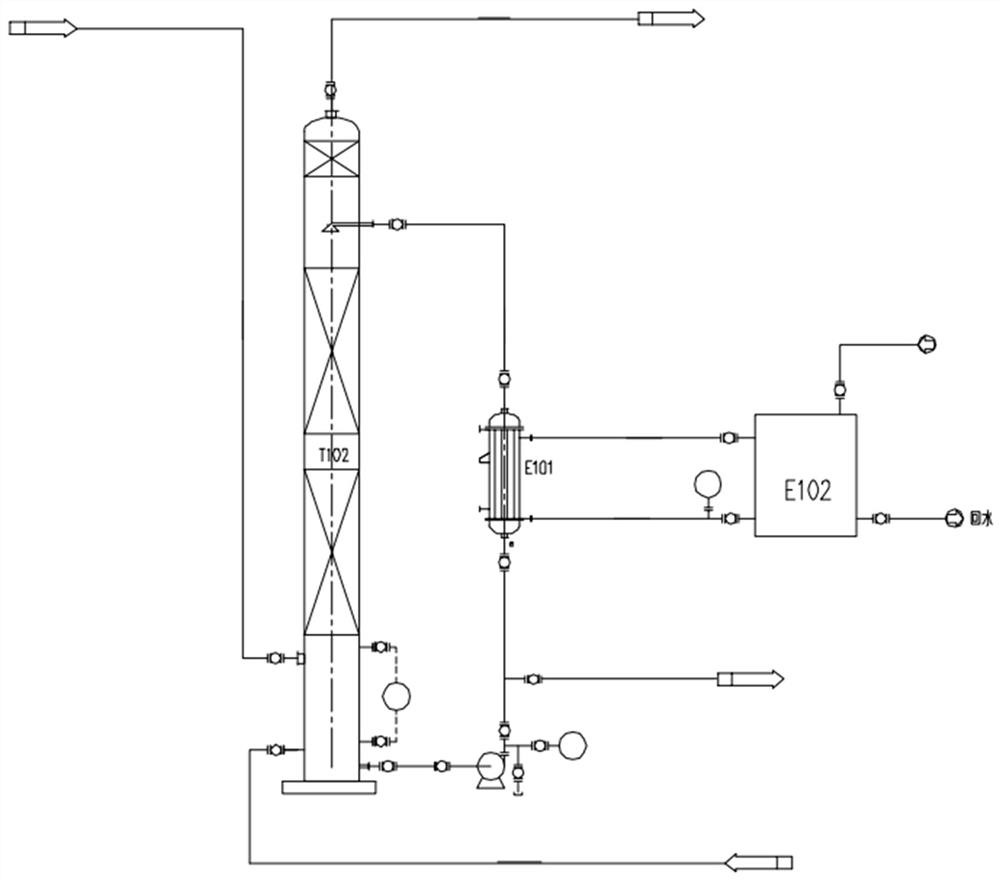

[0039] Such as Figure 1~5 As shown, the present embodiment provides a method for utilizing Mannheim furnace tail gas to produce reagent hydrochloric acid, specifically comprising the following process:

[0040] (1) M101 Mannheim furnace tail gas treatment: absorb impurity gas with concentrated sulfuric acid

[0041] After the reaction of potassium chloride+concentrated sulfuric acid→potassium sulfate+hydrogen chloride gas in the Mannheim furnace, the gas impurities include nitrogen oxides, metal salts, sulfides, iron ions, organic VOCs, carbon oxides, bromide ions, etc. Hydrogen chloride gas accounts for about 32%~42% of it, and the tail gas is used as the raw material for the production of reagent hydrochloric acid. After the tail gas is guided into the sulfuric acid scrubber T104 by P106, it enters the sulfuric acid scrubber T104 from the lower part of the sulfuric acid scrubber T104. Use the P105 circulation pump to pump the concentrated sulfuric acid into the spray head ...

Embodiment 2

[0054] The method for producing reagent hydrochloric acid in this example is the same as that in Example 1, the difference being: (3) the first filter G101 in the primary filtration is filled with glass fiber and modified expanded graphite, and the preparation method of the expanded graphite is:

[0055] Put the spare expanded graphite into 32% hydrochloric acid solution, stir, filter, wash, dry at 105°C, and slowly dissolve chitosan with water to form a chitosan solution. Slowly add the dried expanded graphite into the chitosan solution, stir to make it fully mixed, and dry at 110° C. for 6 hours to obtain the chitosan / expanded graphite adsorbent. Wherein the mass ratio of chitosan to expanded graphite is 1:20.

Embodiment 3

[0057] The method for producing reagent hydrochloric acid in this example is the same as that in Example 2, the difference being that in (6) the S101 resin tank of the secondary filter is filled with adsorption resin, and the surface of the adsorption resin is loaded with β-cyclodextrin, and the adsorption resin is The β-cyclodextrin, polyol, isocyanate and foaming agent are polymerized under the action of a catalyst so that the β-cyclodextrin is loaded in the polyurethane cross-linked network, which has a good adsorption effect on organic matter and metal ions.

[0058] Specifically, the preparation method of the modified adsorption resin is:

[0059] Dissolve 2.0g of β-cyclodextrin in water; then dissolve 50g of polypropylene glycol, 100g of diphenylmethane diisocyanate, and 0.25g of initiator in deionized water to obtain a prepolymer system; among them, polypropylene glycol, diphenyl The mass ratio of methyl methane diisocyanate is 1:2, and the initiator adopts stannous oct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com