Insect-proof durable filament for plastic woven bags

A plastic woven bag, a durable technology, applied in the field of plastic woven bags, can solve the problems of rough surface of polypropylene plastic flat wire, easy to be bitten by insects, weak flat wire, etc., to improve the appearance quality and flexibility, and avoid being easy to be insects Bite, the effect of expanding the range of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

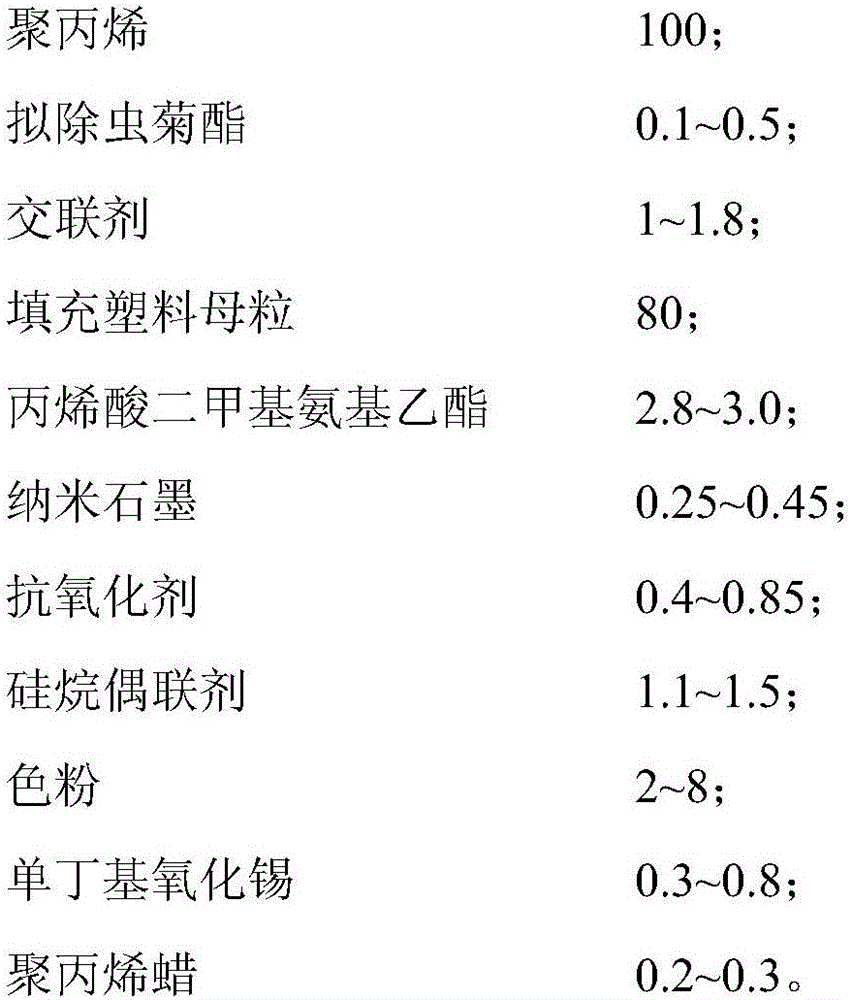

[0014] An insect-proof durable plastic woven bag silk is characterized in that it consists of the following raw materials in parts by weight:

[0015]

[0016] The step of preparing superfine talcum powder filling masterbatch is to first activate 3000 mesh superfine talc powder with 3-aminopropyltriethoxysilane for 15min, then use polypropylene wax as dispersant, and add monobutyltin oxide as The thermal stabilizer uses polypropylene as the carrier to make filler masterbatches for polypropylene flat filaments.

Embodiment 2

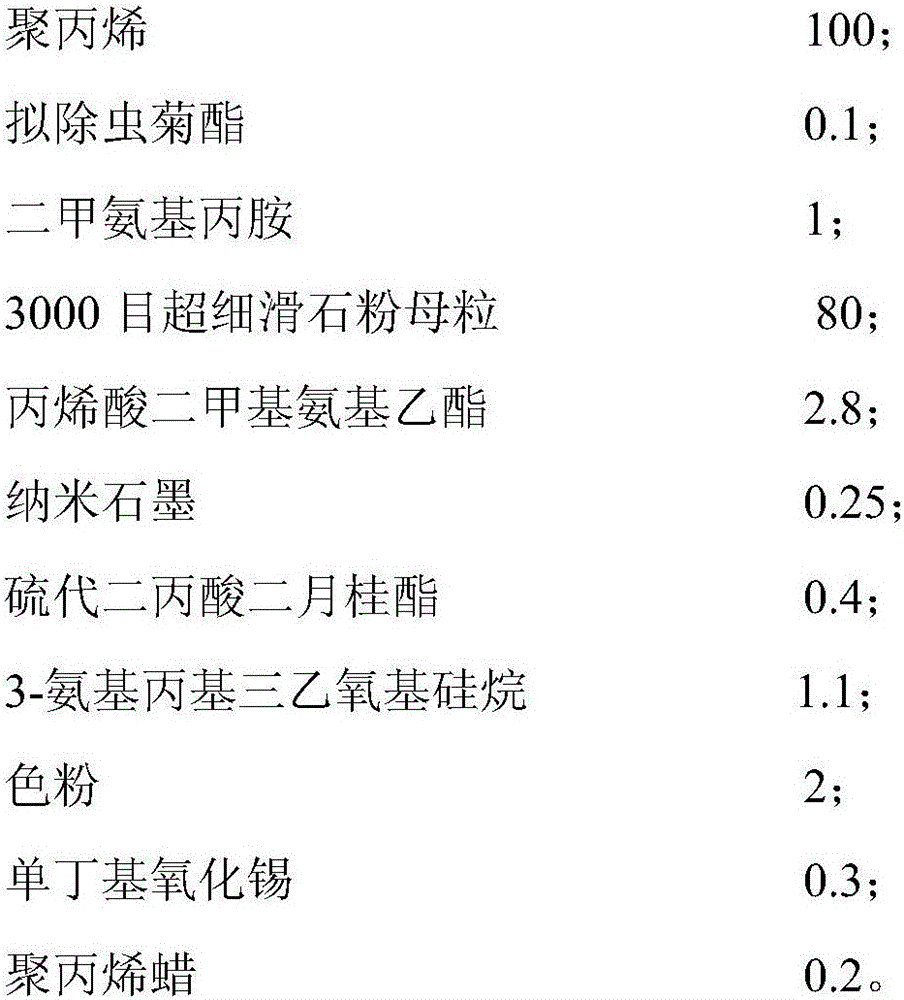

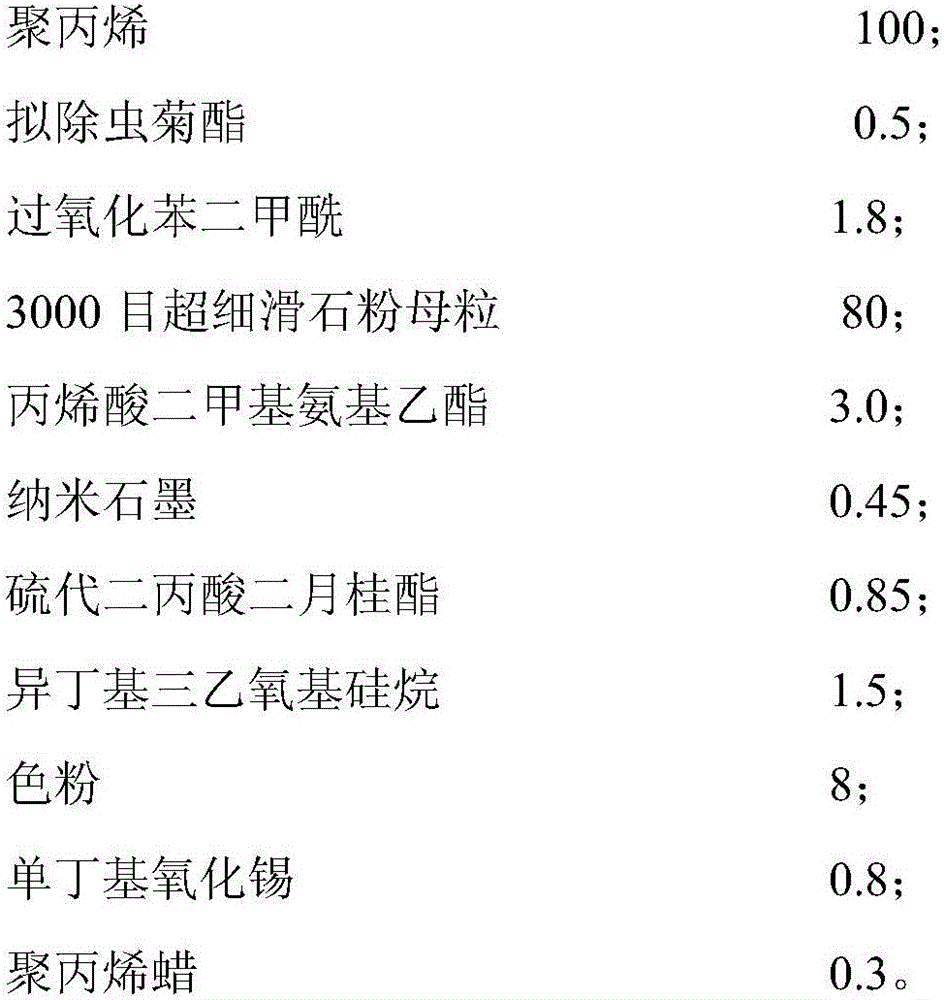

[0018] An insect-proof durable plastic woven bag silk is characterized in that it consists of the following raw materials in parts by weight:

[0019]

[0020] The step of preparing the superfine talcum powder filling masterbatch is to first activate the 3000 mesh superfine talc powder masterbatch with isobutyltriethoxysilane for 15min, then use polypropylene wax as a dispersant, and add monobutyltin oxide as a The thermal stabilizer uses polypropylene as the carrier to make filler masterbatches for polypropylene flat filaments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com