Natural carotene microcapsule and preparation method thereof

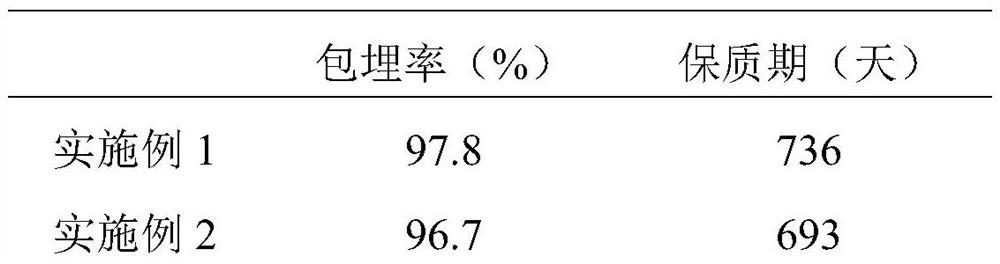

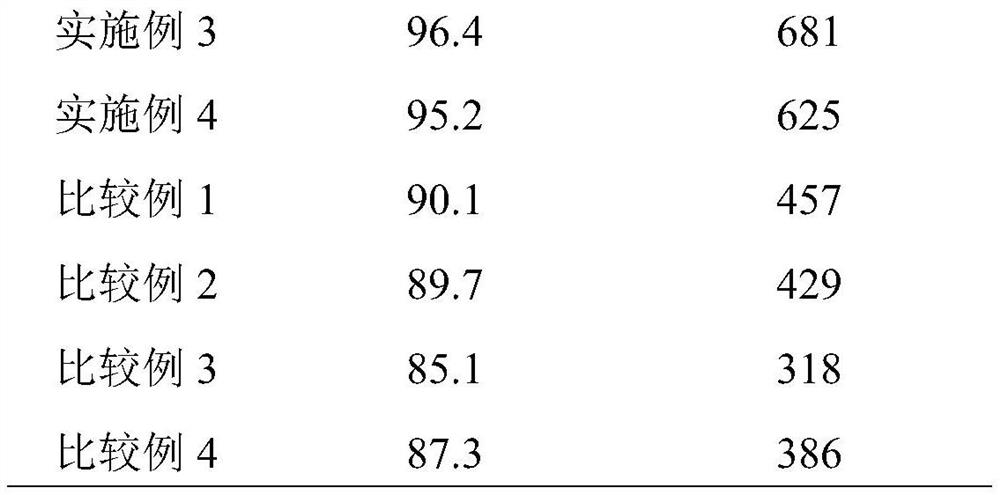

A carotene and microcapsule technology, applied in food science, food preservation, food drying and other directions, can solve problems such as no more than 95%, and achieve the effects of stable photothermal properties, long storage time and good embedding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] Embodiments of the present invention also provide a preparation method of natural carotene microcapsules, the preparation method comprising the following steps:

[0026] (1) prepare materials by weight;

[0027] (2) Add wall material, D-sodium erythorbate, maltodextrin, sodium tripolyphosphate, and citric acid into water, heat at 70-80°C, stir until dissolved, keep warm for later use, and obtain an aqueous phase;

[0028] (3) Mix the core material and vegetable oil, and heat at 140-150°C under the condition of inert gas to obtain the oil phase;

[0029] (4) mixing and dispersing the oil phase and the water phase to obtain a primary emulsion; homogenizing the primary emulsion to obtain a microemulsion;

[0030] (5) The microemulsion is spray-dried to obtain natural carotene microcapsules, the spray-drying inlet temperature is 170-190°C, and the spray-drying outlet temperature is 60-70°C.

[0031] In an embodiment of the present invention, in step (2), keep warm at 45-5...

Embodiment 1

[0039] Embodiment 1 of the present invention provides a kind of natural carotene microcapsules, and this natural carotene microcapsules comprises the component of following parts by weight:

[0040] 15 parts of natural carotene, 50 parts of wall material, 15 parts of perilla oil, 5 parts of sodium D-isoascorbate, 2 parts of sodium tripolyphosphate, 1.5 parts of citric acid, and 24 parts of maltodextrin; wherein, the weight of wall material is as follows The composition of parts: 35 parts of starch sodium octenyl succinate, 8 parts of xylitol, 0.8 parts of tannic acid and 25 parts of zein.

[0041] The natural carotene microcapsules are prepared by the following method:

[0042] (1) prepare materials by weight;

[0043] (2) Add starch sodium octenyl succinate, xylitol, tannic acid, zein, sodium D-isoascorbate, maltodextrin, sodium tripolyphosphate, and citric acid into deionized water, and heat at 75°C Heating under low temperature, stirring until dissolved, obtaining the wat...

Embodiment 2

[0048] Embodiment 2 of the present invention provides a kind of natural carotene microcapsule, and this natural carotene microcapsule comprises the following components by weight:

[0049] 8 parts of natural carotene, 25 parts of wall material, 10 parts of perilla oil, 3 parts of sodium D-erythorbate, 1.6 parts of sodium tripolyphosphate, 1.2 parts of citric acid, and 20 parts of maltodextrin; wherein, the weight of wall material is as follows The composition of parts: 30 parts of starch sodium octenyl succinate, 5 parts of xylitol, 0.5 parts of tannic acid and 20 parts of zein.

[0050] The natural carotene microcapsules are prepared by the following method:

[0051] (1) prepare materials by weight;

[0052] (2) Add starch sodium octenyl succinate, xylitol, tannic acid, zein, sodium D-isoascorbate, maltodextrin, sodium tripolyphosphate, and citric acid into deionized water and heat at 70°C Heating under low temperature, stirring until dissolved, obtaining the water phase, k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com