Multilayer electromagnetic shielding film and preparation method thereof

An electromagnetic shielding film and shielding layer technology, applied in chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problems of time-consuming and labor-intensive, high cost, unsatisfactory shielding effect, etc. And the effect of good toughness, excellent electromagnetic shielding performance and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

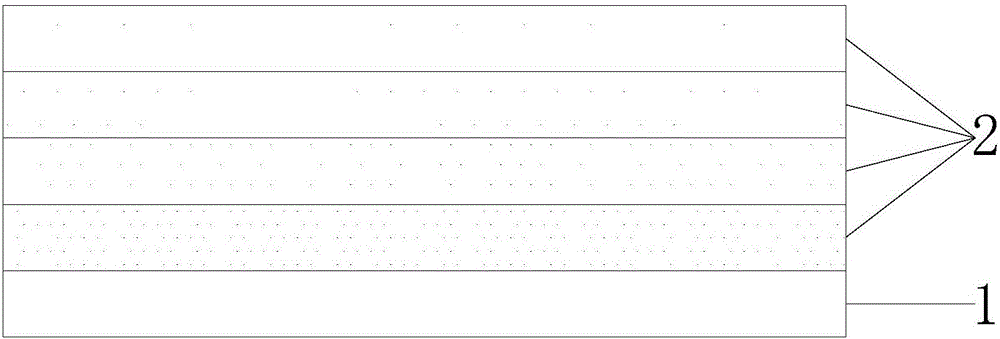

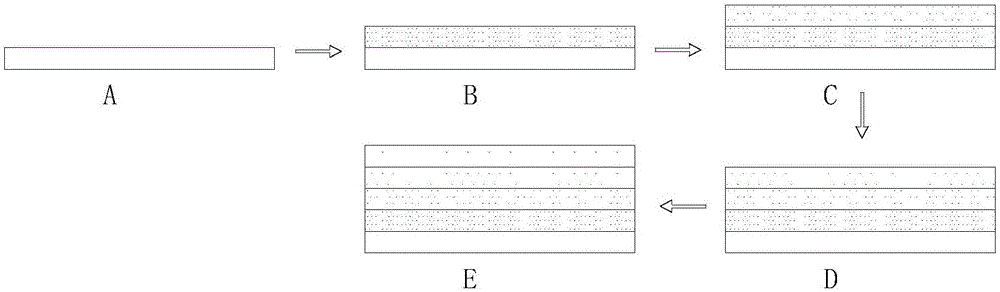

[0042] Step 5, completing the preparation of the five-layer electromagnetic shielding film.

[0043] The invention can prepare the electromagnetic shielding film on a large scale through the above method, and the prepared electromagnetic shielding film has excellent electromagnetic shielding performance, good mechanical strength and toughness.

Embodiment 1

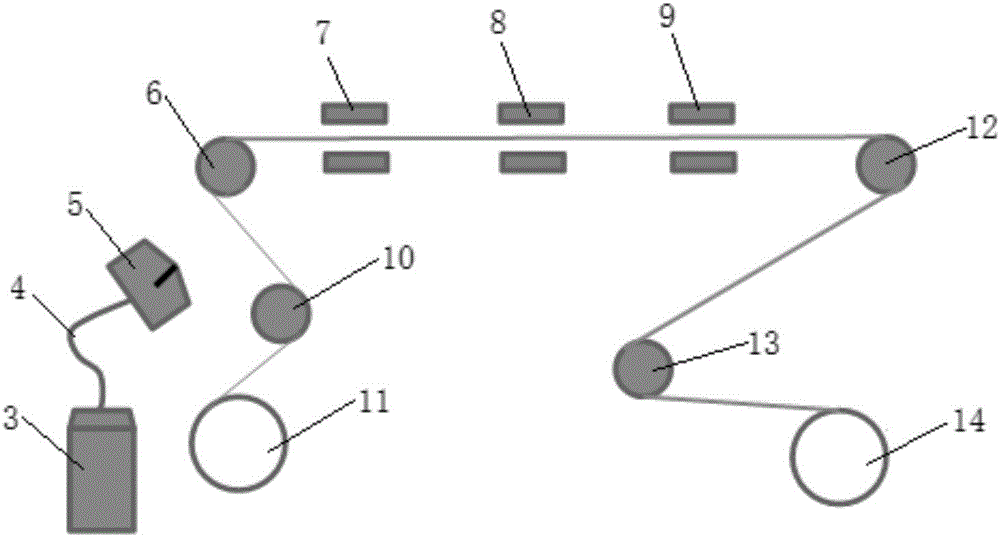

[0045]The polyvinyl butyral (PVB) resin powder is prepared according to the ratio of the solid content of the resin powder to 0.05g / ml, the volume ratio of toluene:ethanol=5:1, and the plasticizer content of 1wt%. , mechanically stirred for 8 hours to reach the complete dissolution of the resin powder; in the PVB resin solution, the silver powder content was respectively: 5wt%, 10wt%, 30wt%, 60wt% to configure the slurry solution, and continue to stir to make the filler particles (silver powder) in the solution Stir for 5 hours to fully mix, perform defoaming treatment before casting, carry out distributed casting according to the design structure sequence, adjust the width of the knife edge gap of the machine head, the discharge pressure of the slurry tank, the winding speed of the PET film tape, and the slurry in the slurry The material tank is pumped into the knife-edge mold through the plastic tube, and the slurry is sprayed to the opposite PET film tape through the narrow ...

Embodiment 2

[0047] The polyvinyl butyral (PVB) resin powder is prepared according to the ratio of resin powder solid content of 0.25g / ml, toluene:ethanol volume ratio=3:1, and plasticizer content of 2wt% in the reactor. , mechanical stirring reached the complete dissolving of resin powder in 8 hours; In PVB resin solution, by nickel powder content, be respectively: 10wt%, 20wt%, 40wt%, 80wt% carry out configuration slurry solution, continue to stir and make filler particle (nickel powder) in Stir in the solution for 5 hours to fully mix, perform defoaming treatment before casting, carry out distributed casting according to the sequence of the design structure, adjust the width of the knife edge gap of the machine head, the discharge pressure of the slurry tank, the winding speed of the PET film, and the slurry In the slurry tank, it is drawn into the knife-edge mold through the plastic tube, and the slurry is sprayed to the opposite PET film tape through the narrow slit of the knife edge u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com