Method for preparing fuel cell membrane electrode with sealing frame

A fuel cell membrane and sealing technology, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of catalyst slurry waste, low production efficiency, and long hot pressing time, and achieve simple and easy engineering process and simplified forming process , Exclude the effect of swelling and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038] The invention aims to provide a membrane electrode preparation method with less damage to the catalytic layer, high precision and good stability.

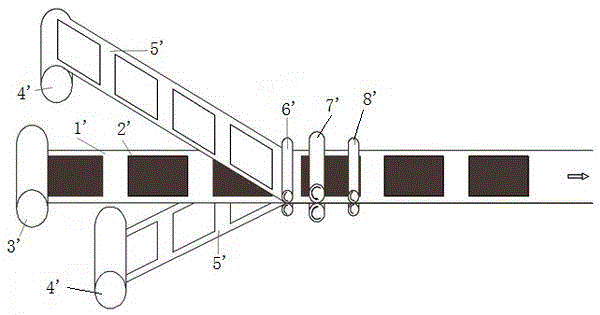

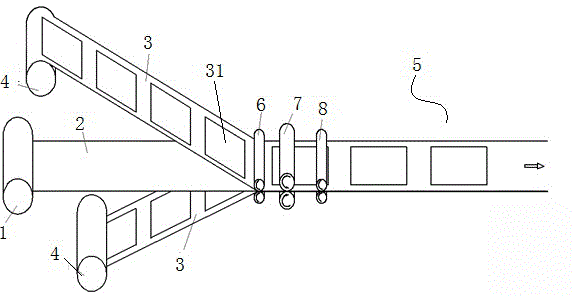

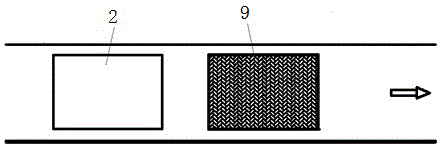

[0039] see figure 2 , the polymer electrolyte membrane 2 is wound on the first feed roller 1, and the two sides of the polymer electrolyte membrane 2 are not coated with electrodes; the sealing frame 3 is wound on the second feed roller 4 to realize feeding, and the two second The feed rollers 4 are symmetrically distributed on the upper and lower sides of the first feed roller 1, and the first feed roller 1 and the two second feed rollers 4 are located on the same side of the heat press table 5. When feeding, the sealing frame 3 The side facing the polymer electrolyte membrane 2 is coated with hot-melt glue, wherein the sealing frame 3 has an opening 31 in the middle, and is subsequently bonded to the edge of the polymer electrolyte membrane 2 .

[0040] During the preparation process, the polymer electrolyte membrane 2 f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com