Forming method for cylindrical shell piece with flanged holes

A technology of flanging holes and parts, which is applied in the field of sheet metal forming, can solve the problems of difficult part forming, unloading, poor surface quality, etc., and achieve the effects of reducing forming tooling, ensuring product quality, and simplifying the forming process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following is an example of a typical cylindrical shell part with flanged holes.

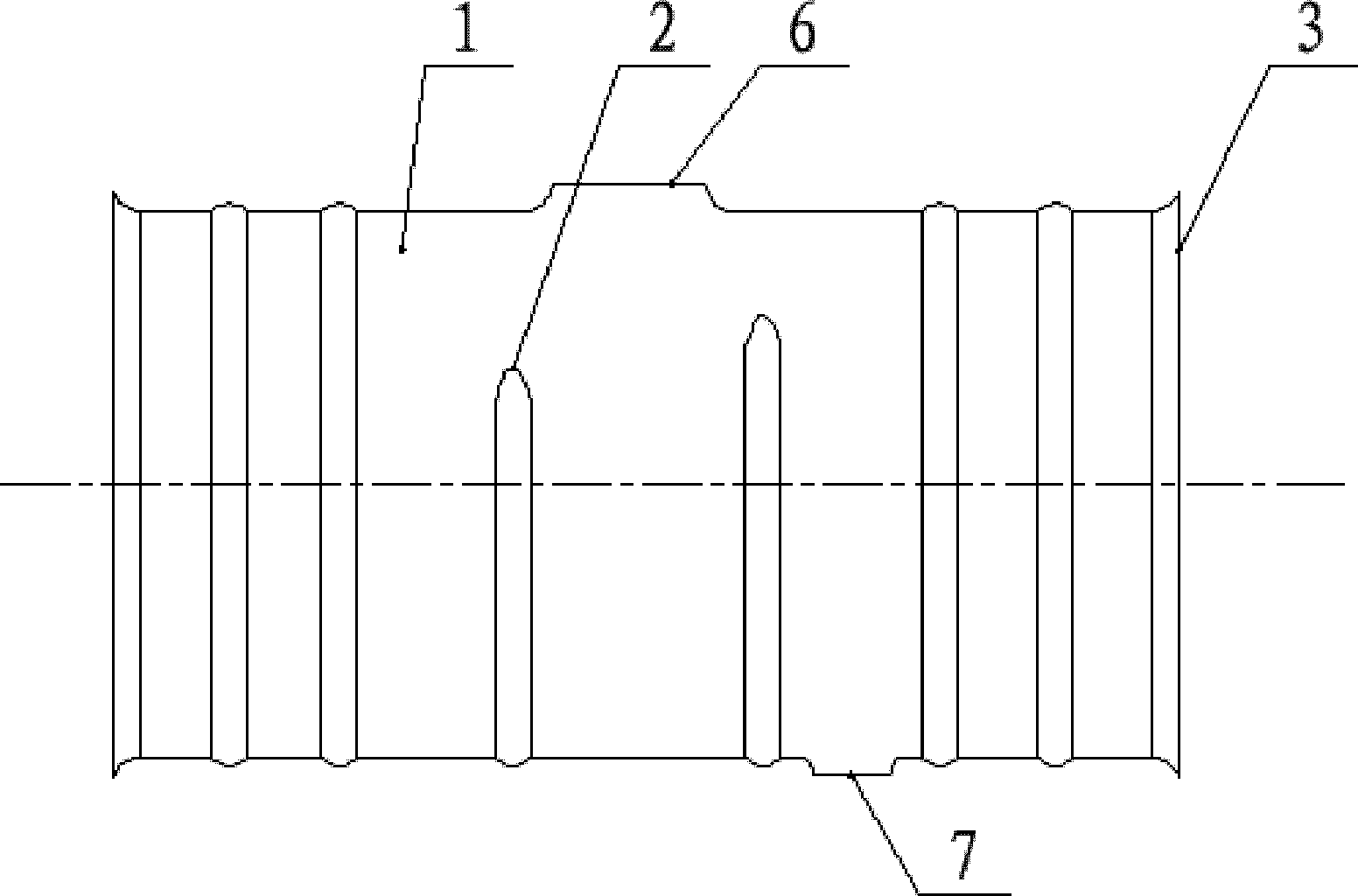

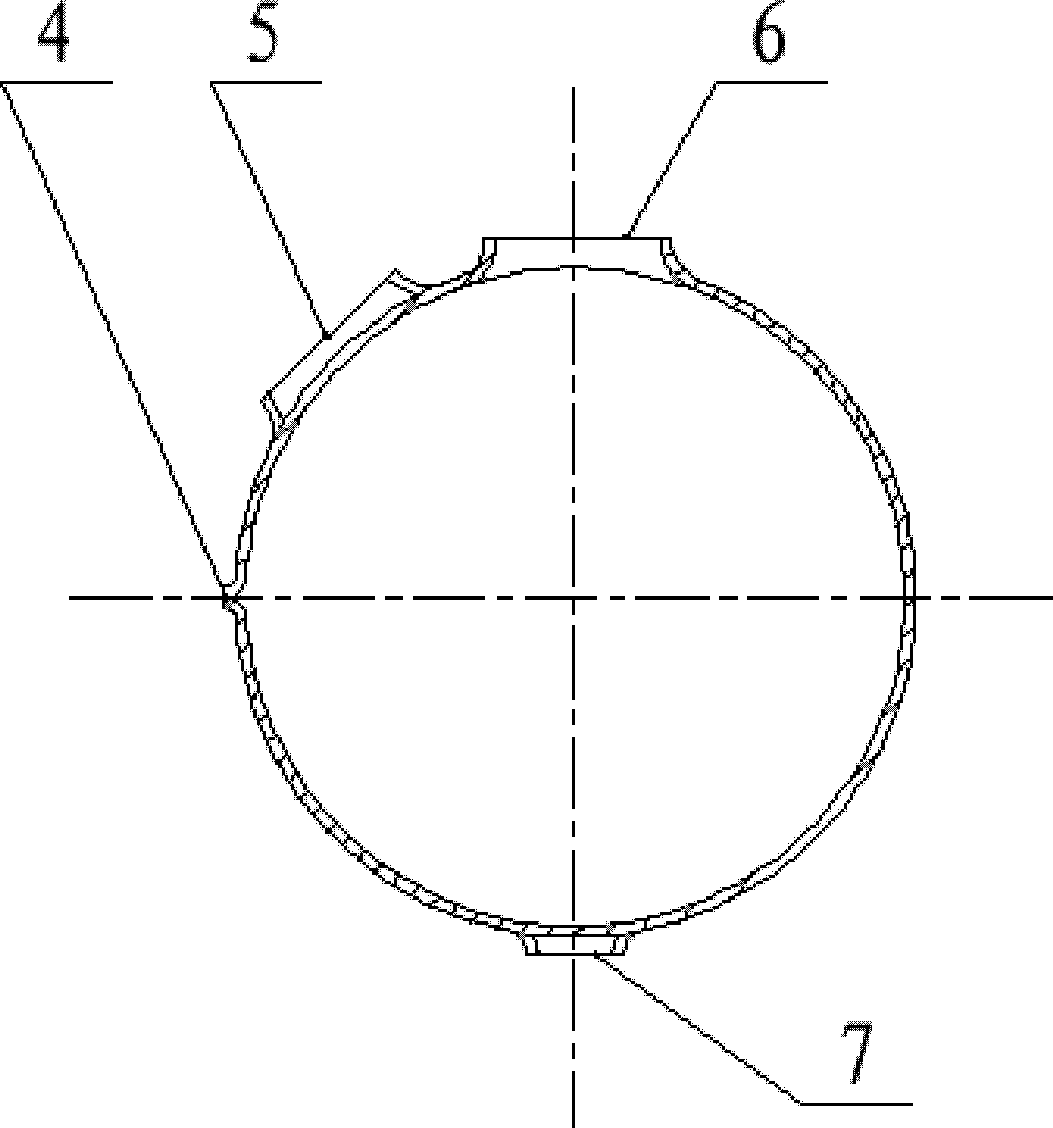

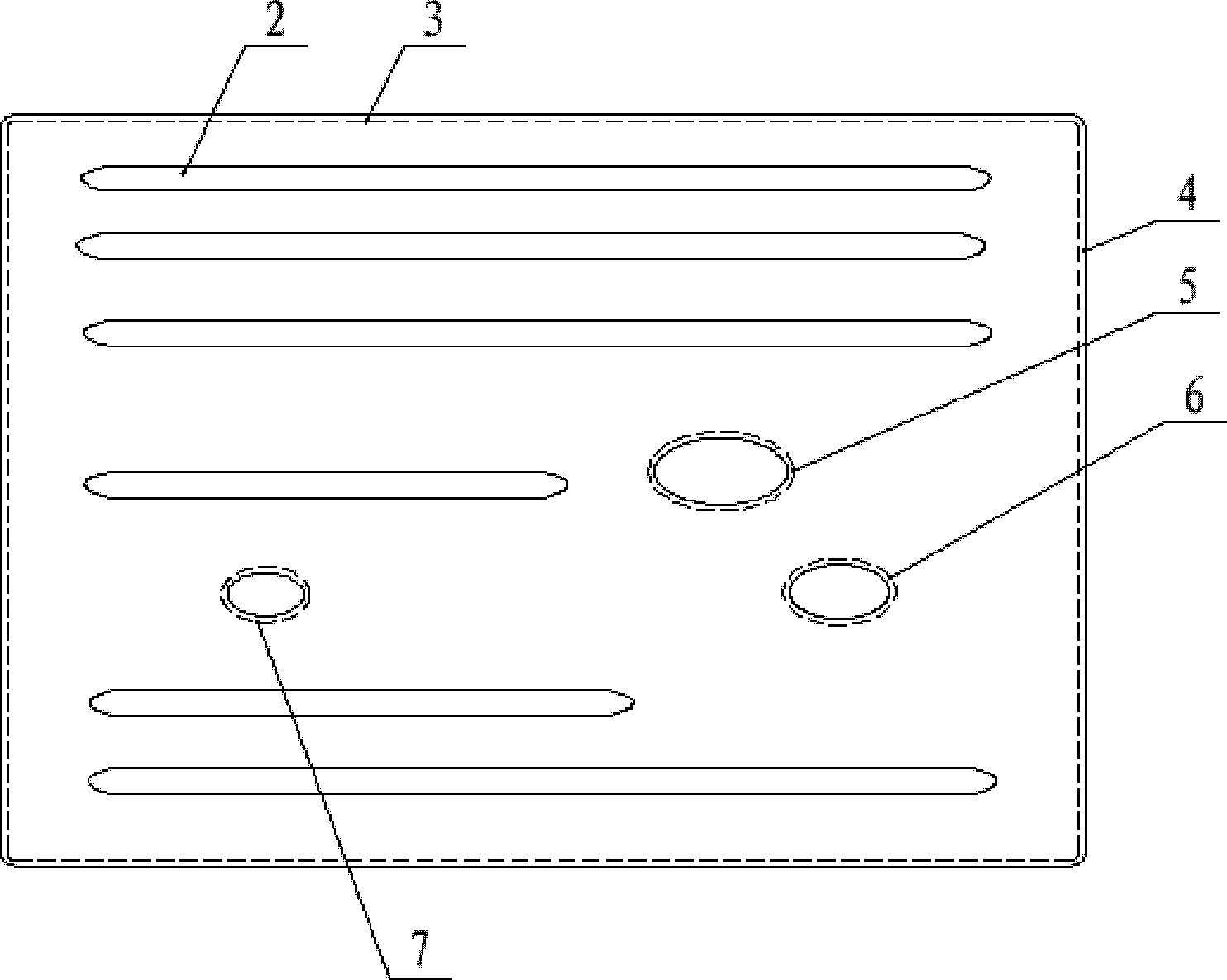

[0025] See attached picture, figure 1 It is a schematic diagram of the cylindrical multi-mouth shell parts. According to the structural design of the aircraft, the cylindrical shell parts are made of anti-rust aluminum sheets, which are welded and assembled with multiple parts such as the tank cover, tank bottom, and conduits to form a fuel tank assembly. The part has a butt weld 4 in the cylinder height direction, the cylinder wall has reinforcing ribs 2 along the circumferential direction, and there are special circular first flanging holes 5 with different positions and sizes along the normal direction of the cylinder rotation axis. Flange hole 6, the 3rd flange hole 7 (as figure 2 Shown), used for the butt joint of fuel tank and oil pipe, there are flanges 3 at both ends of the cylinder and at the edge of the weld. For the forming of this part, the curling of the cylinder, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com