Continuous manufacturing method for vacuum insulation material

A technology of vacuum heat insulating material and manufacturing method, which is applied in the direction of manufacturing tools, protecting pipes through heat insulation, heat exchange equipment, etc. The effect of reducing production costs and reducing wastage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

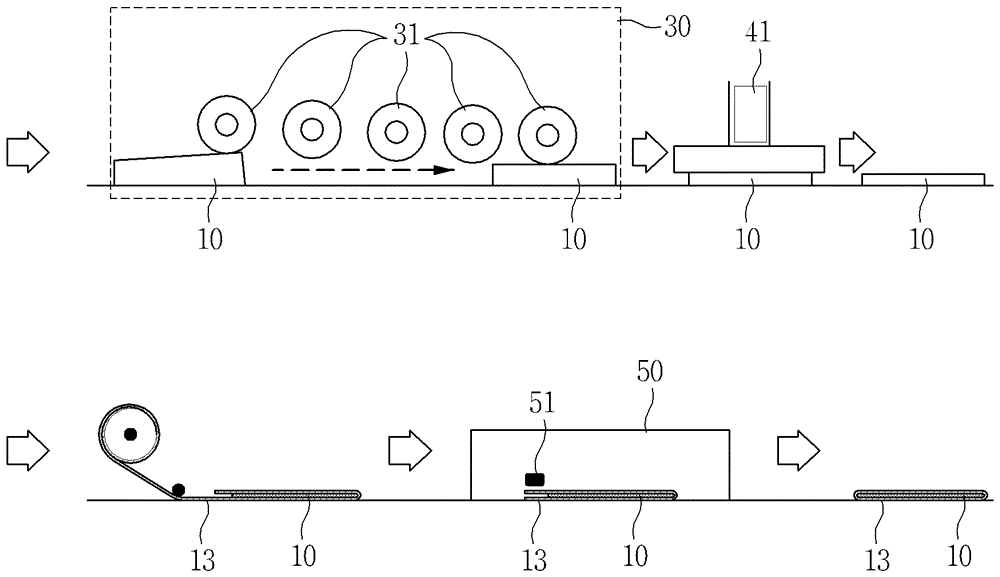

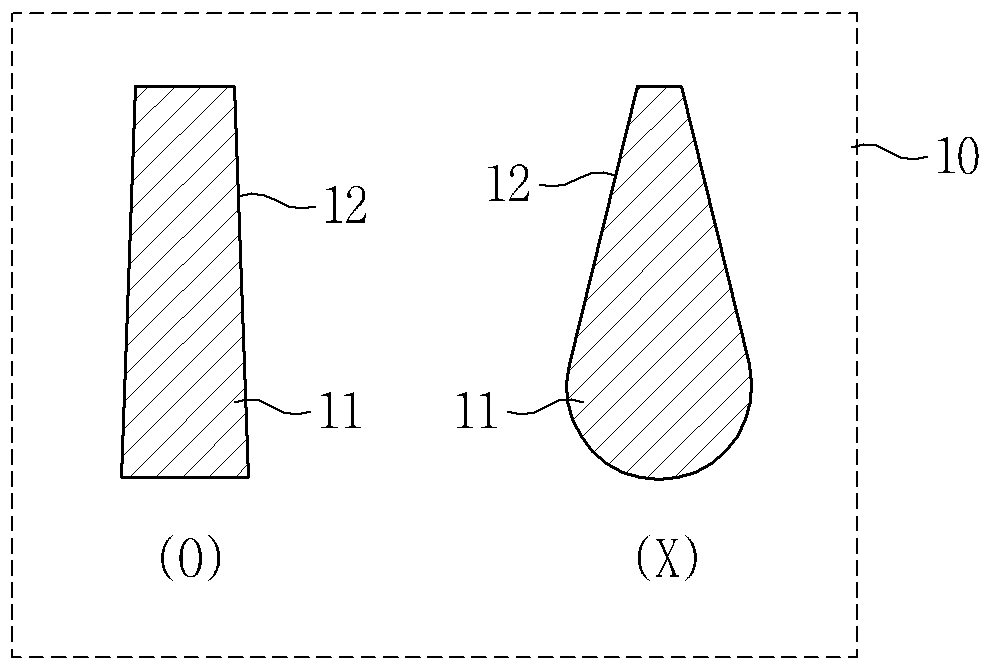

[0030] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings. figure 1 is a schematic diagram of a continuous manufacturing process of a vacuum insulation material according to an embodiment of the present invention. figure 2 is a schematic illustration of an implementation of a permeable inner wrap filled with porous insulation.

[0031] In order to achieve the above object, the continuous manufacturing method of vacuum insulation material according to the present invention comprises a first step of placing the porous insulation material into an inner package with permeability, for example, into a Inner wrapping, and sealing the inner wrapping.

[0032] Although figure 1 Shown is the continuous manufacturing method of the vacuum insulation material, however, figure 1 does not show the first step of placing the porous insulation in the permeable inner package and sealing the package. In the method according to the inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com