Tool head and method for controlling buckling deformation in thin plate die-free gradual edge turning process

A tool head and flanging technology, which is applied in the field of tool heads to control the warpage and deformation of thin plates during the dieless progressive flanging process, to achieve the effects of simple structure, elimination of longitudinal warping, and easy forming process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

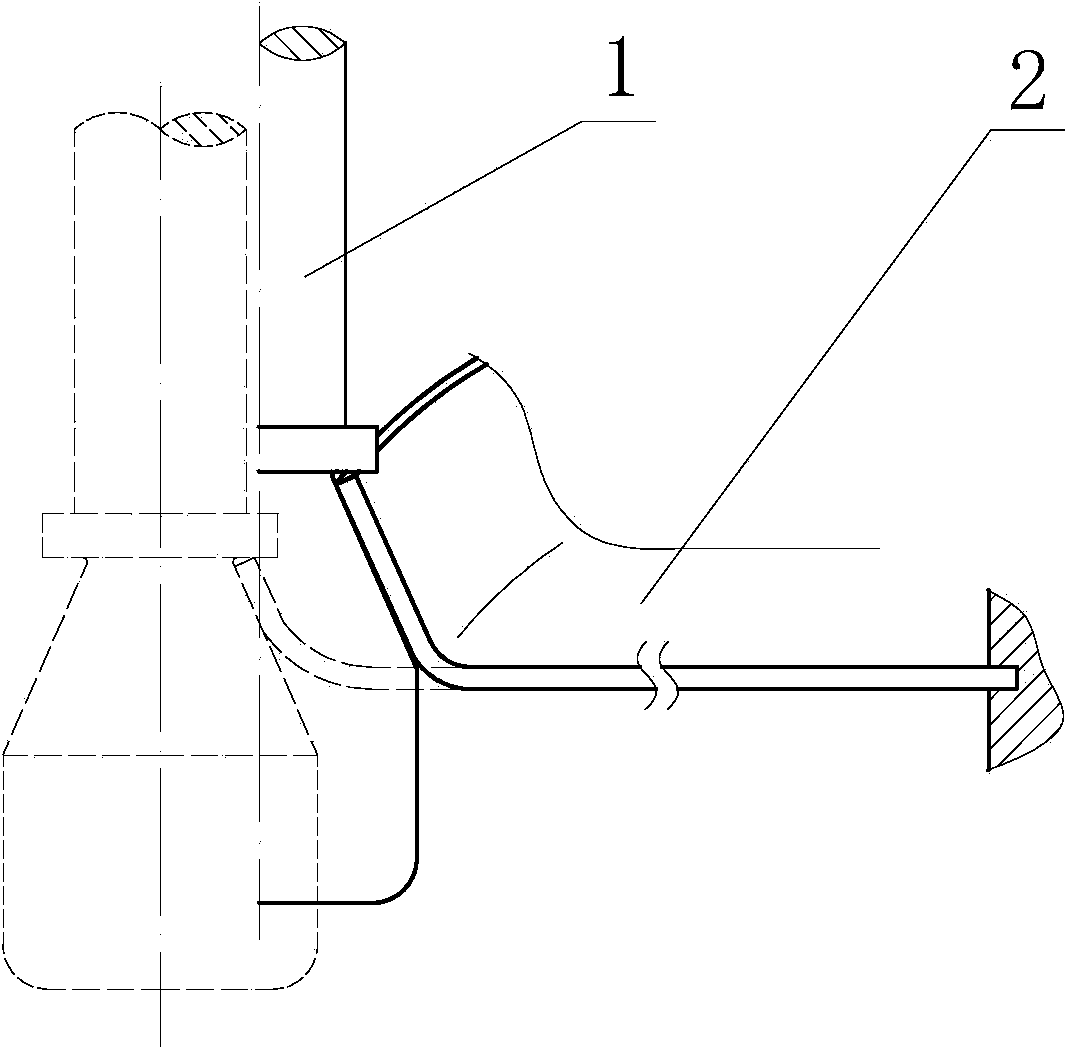

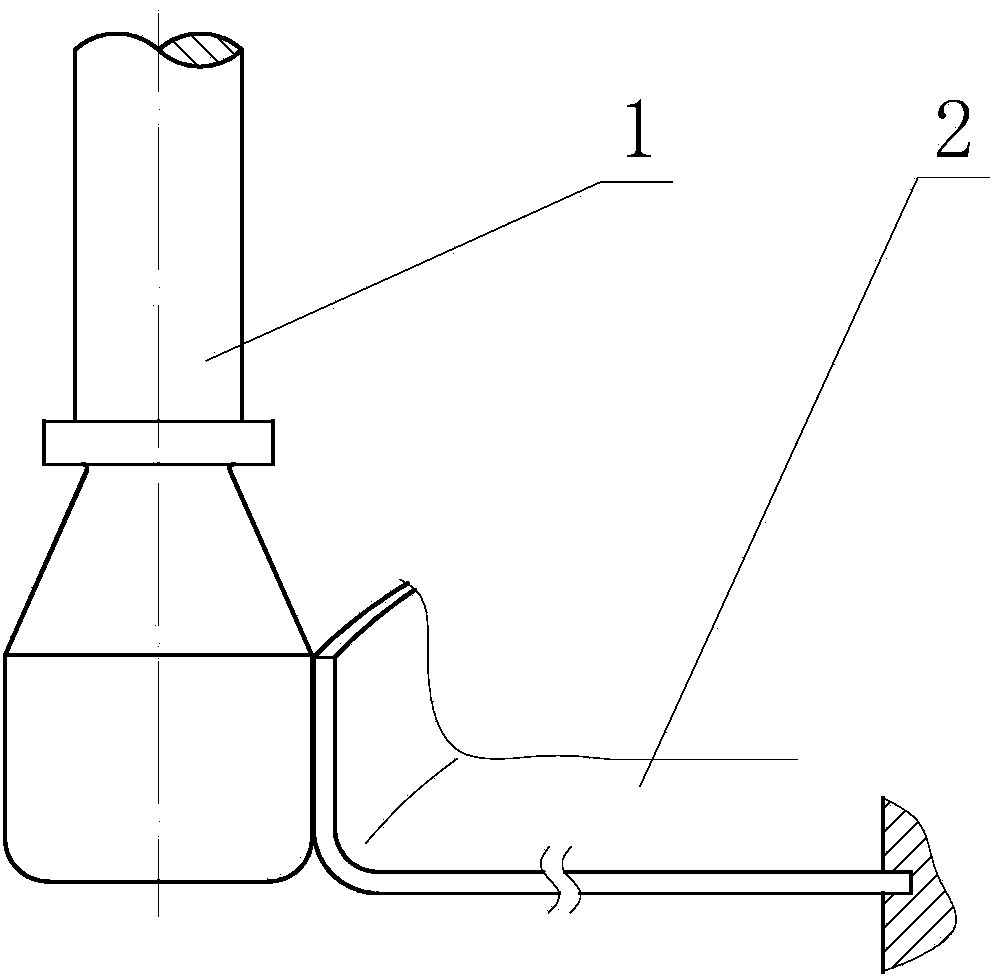

[0020] The specific implementation of the present invention will be described below by taking the edge flanging of an Al 6061 aluminum alloy sheet with a thickness of 1 mm and a length and width of 100 mm and 100 mm respectively on the progressive forming equipment as an example.

[0021] The entire flanging forming process uses a tool head 1 in the shape of a rotating body. The upper end of the tool head 1 is a slender cylinder with a diameter of 10mm, and the lower end of the slender cylinder is connected to a disc with a diameter of 15mm and a thickness of 3mm. The bottom surface of the disk is connected with a truncated cone with an upper diameter of 8 mm and a lower diameter of 20 mm. The upper end of the truncated cone and the bottom surface of the disk are smoothly connected through a transition fillet with a radius of 0.5 to 1 mm; The angle is 30°, and the lower end is connected to a large cylinder with a diameter of 20mm and a height of 15mm. There is a round corner tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com