Photosensitive resin composition

A technology of photosensitive resin and composition, which is applied in the direction of optics, optomechanical equipment, printed circuit, etc., can solve problems such as inability to correspond to circuit patterns, decrease in clarity, and poor shape, so as to suppress line peeling and defect, simplify Pattern forming process, effect of preventing loss of definition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] The preparation method of the above-mentioned photosensitive resin composition of the present invention is not limited to a specific method. For example, after mixing the above-mentioned components in a predetermined ratio, pass through mixing equipment such as a three-roll machine, a ball mill, and a sand mill at room temperature, or The photosensitive resin composition of the present invention is prepared by kneading or mixing with stirring equipment such as a high-speed mixer and a planetary mixer. In addition, pre-kneading or pre-mixing may be performed as necessary before the above-mentioned kneading or mixing.

[0060] Next, the usage method of the photosensitive resin composition of this invention mentioned above is demonstrated. Here, the case where the photosensitive resin composition of the present invention is coated on a circuit board to form a solder resist film will be described as an example.

[0061] For example, on a printed circuit wiring board having...

Embodiment 1~10、 comparative example 1~5

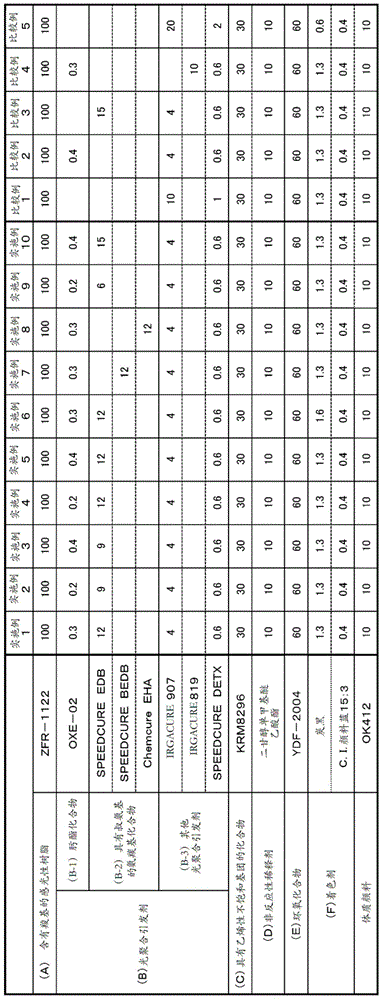

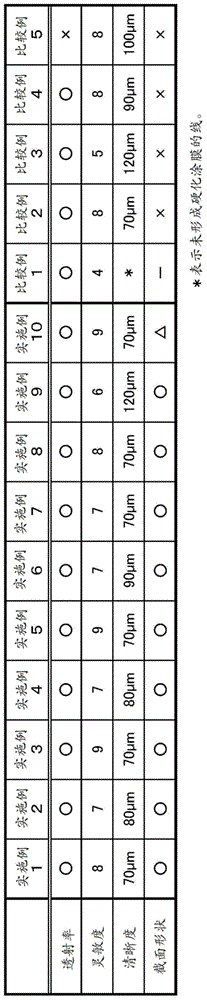

[0066] Mix the components shown in the following Table 1 according to the mixing ratio shown in the following Table 1, and mix and disperse them at room temperature using a three-roll machine to prepare the photosensitive resins used in Examples 1-10 and Comparative Examples 1-5. resin composition. Unless otherwise specified, the compounding quantity of each component shown in following Table 1 represents a mass part.

[0067] Table 1

[0068]

[0069] In addition, the detail of each component in Table 1 is as follows.

[0070] (A) Photosensitive resin containing carboxyl group

[0071] · ZFR-1122: An acid anhydride additive of bisphenol F type epoxy acrylate, manufactured by Nippon Kayaku Co., Ltd.

[0072] (B) Photopolymerization initiator

[0073] (B-1) Oxime ester compound

[0074] OXE-02: ethyl ketone, 1‐[9‐ethyl‐6‐(2‐methylbenzoyl)‐9H‐carbazole‐3‐yl]‐, 1‐(O‐acetyloxime), BASF Made by the company.

[0075] (B-2) Aminocarbonyl compounds having tertiary amino grou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com