Method and apparatus for forming surface shape, method and apparatus for forming flying surface shape of magnetic head

A technology of magnetic head and specified shape, applied in the directions of magnetic recording, maintaining head frame alignment, head hydrodynamic spacing, etc., can solve the problems of prolonging the manufacturing time, reducing the shape accuracy of the flying surface, increasing the manufacturing cost, etc., and reducing the manufacturing cost. , The effect of shortening the processing time and simplifying the forming process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

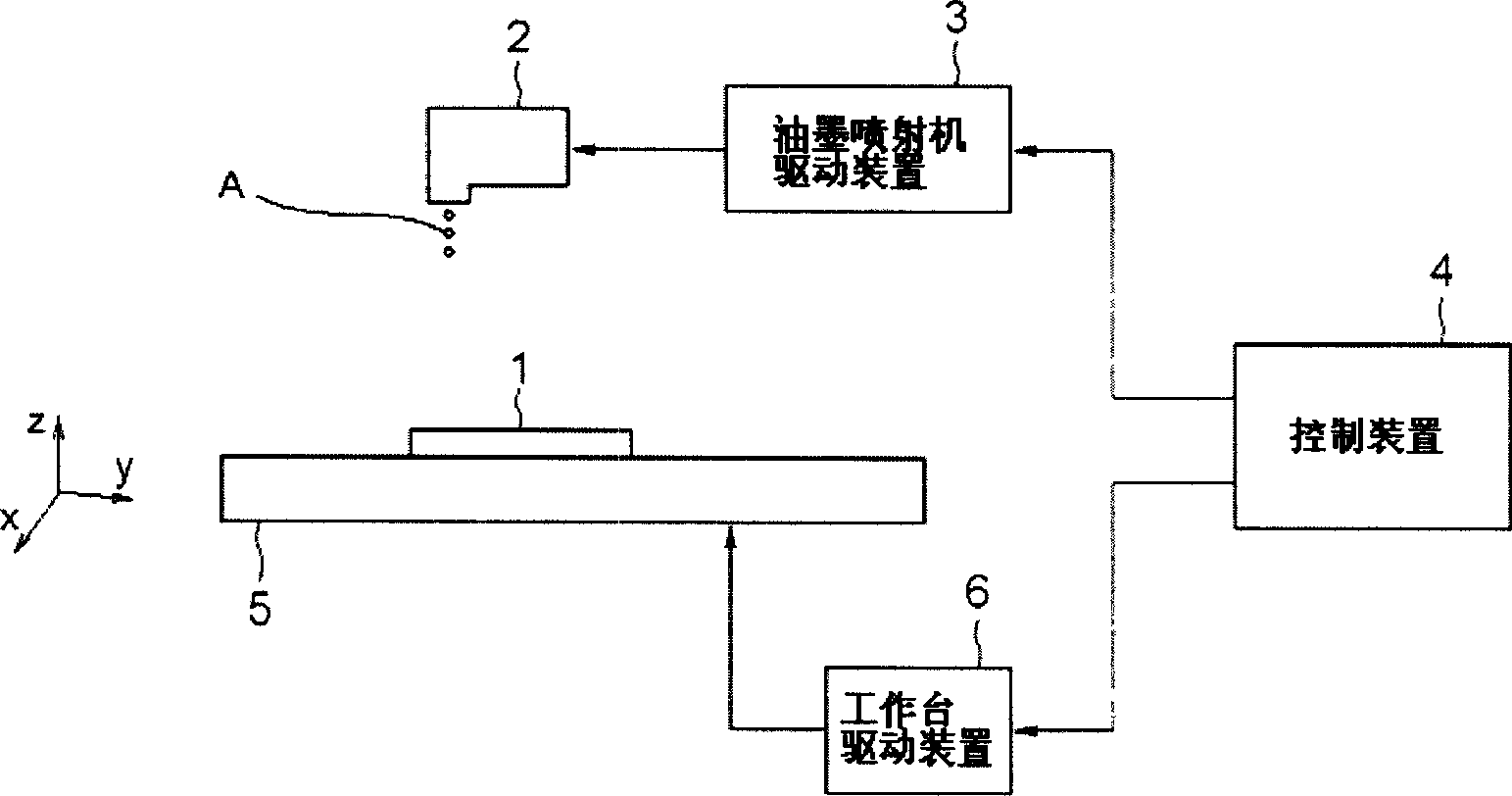

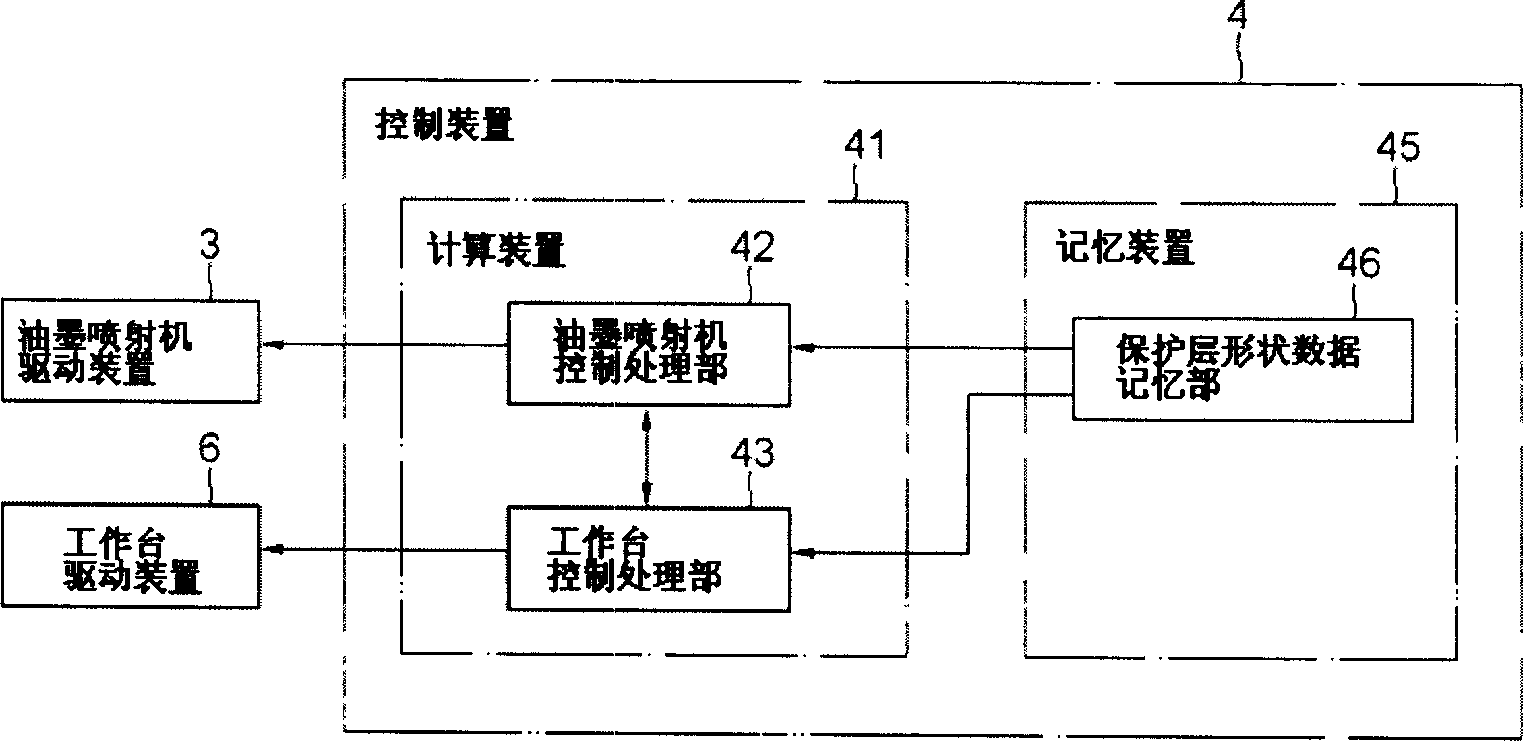

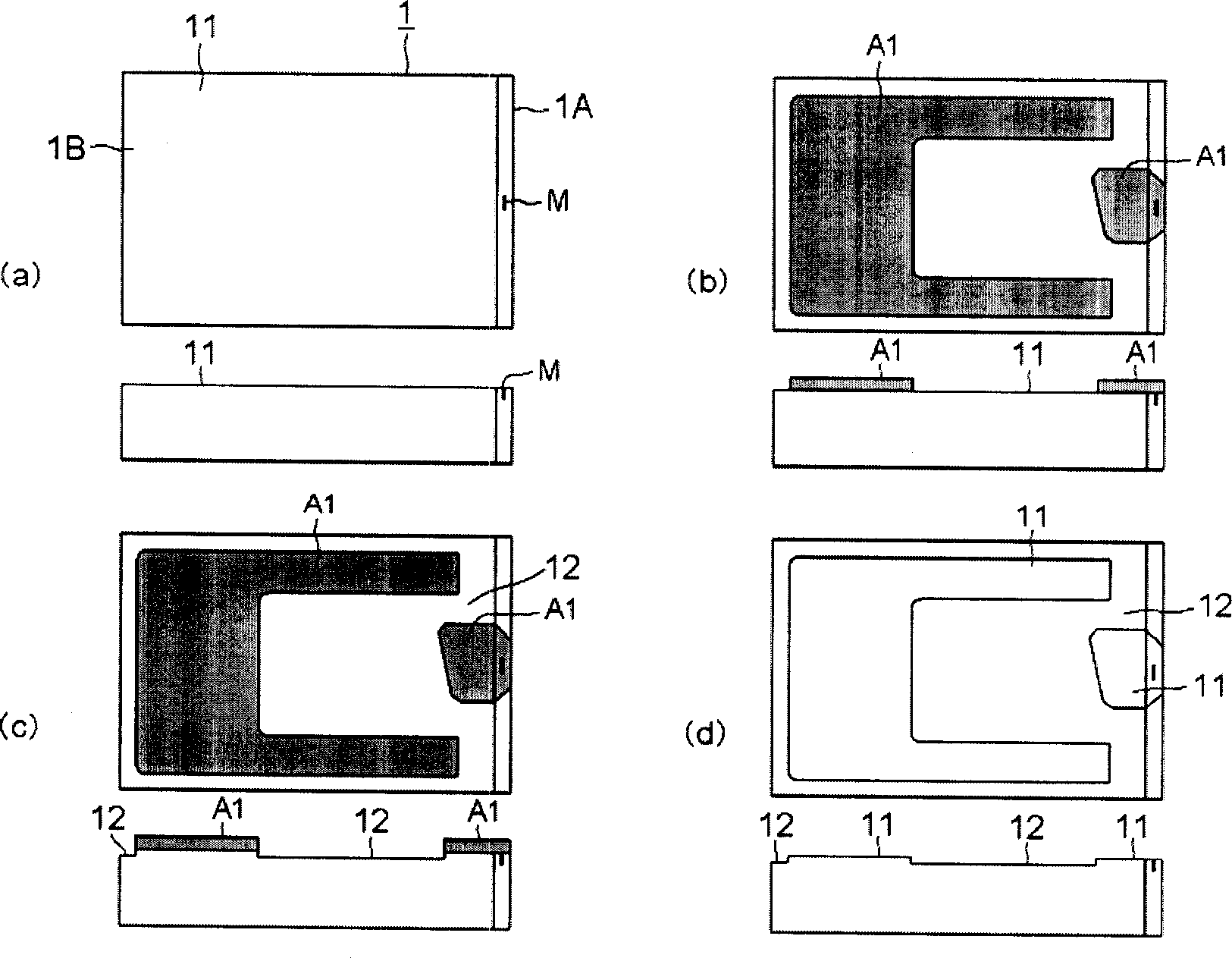

[0040] combine Figure 1 to Figure 5 As shown, the first embodiment of the present invention will be described. figure 1 It is a block diagram showing the structure of the magnetic head flying surface forming device. figure 2 It is a functional block diagram showing the structure of the control device. Figure 3 to Figure 4 It is an explanatory diagram showing the state when the flying surface of the magnetic head is formed. Figure 5 It is a flow chart of the operation of the surface shape forming device.

[0041] [constitute]

[0042] Such as figure 1 As shown, the flying surface forming device (surface shape forming device) of the magnetic head related to the present invention includes: the ink ejection device 2 (protective layer ejection device (protective layer forming device) for the protective layer material A of the protective layer formed by ejecting the protective layer of the prescribed shape to the magnetic head 1. device)), an ink jet driving device 3 that...

Embodiment 2

[0072] Next, combine Figure 6 to Figure 9 A second embodiment of the present invention will be described. Image 6 It is a block diagram showing the structure of the magnetic head flying surface forming apparatus. Figure 7 to Figure 8 It is an explanatory diagram showing the state when the flying surface of the magnetic head is formed. Figure 9 It is the flow chart of the operation of the flight surface forming device.

[0073] [constitute]

[0074] The magnetic head flying surface forming apparatus according to this embodiment further includes laser irradiation devices 7 and 8 (laser irradiation devices) for irradiating laser beams to the protective layer formed on the magnetic head 1 in addition to the structure described in the first embodiment. Correspondingly, the computing device 41 of the control device 4 includes a laser irradiation control processing unit (not shown) for controlling the operation of the laser irradiation devices 7 and 8 .

[0075] Specifically,...

Embodiment 3

[0091] combine Figure 10 Embodiment 3 of the present invention will be described. Figure 10 A shows a schematic diagram of the state when a protective layer is formed on the magnetic head 1 as an etching target, Figure 10 B is a schematic diagram of the state after etching. The process of forming the flying surface of the magnetic head using the above-mentioned method and apparatus for forming the flying surface is described below, but any method and apparatus may be used to form the shape of the magnetic head described below.

[0092] First, as described above, the protective layer material A is sprayed onto the magnetic head 1 by an ink jetting device, and a predetermined shape of the protective layer is drawn. Then, if Figure 10 As shown in A, the periphery of the protective layer A, that is, the corner (Corner) of the protective layer A is rounded and coated. Next, the flying surface of the magnetic head 1 on which the protective layer A is formed is dry-etched using an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com