Half-transmitting LCD and its mfg.method

A technology for a liquid crystal display device and a manufacturing method, which is applied in semiconductor/solid-state device manufacturing, transistors, optics, etc., and can solve problems such as impossible to ensure color characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The transflective liquid crystal display device and its manufacturing method according to the ideal embodiment of the present invention will be described in detail below according to the accompanying drawings.

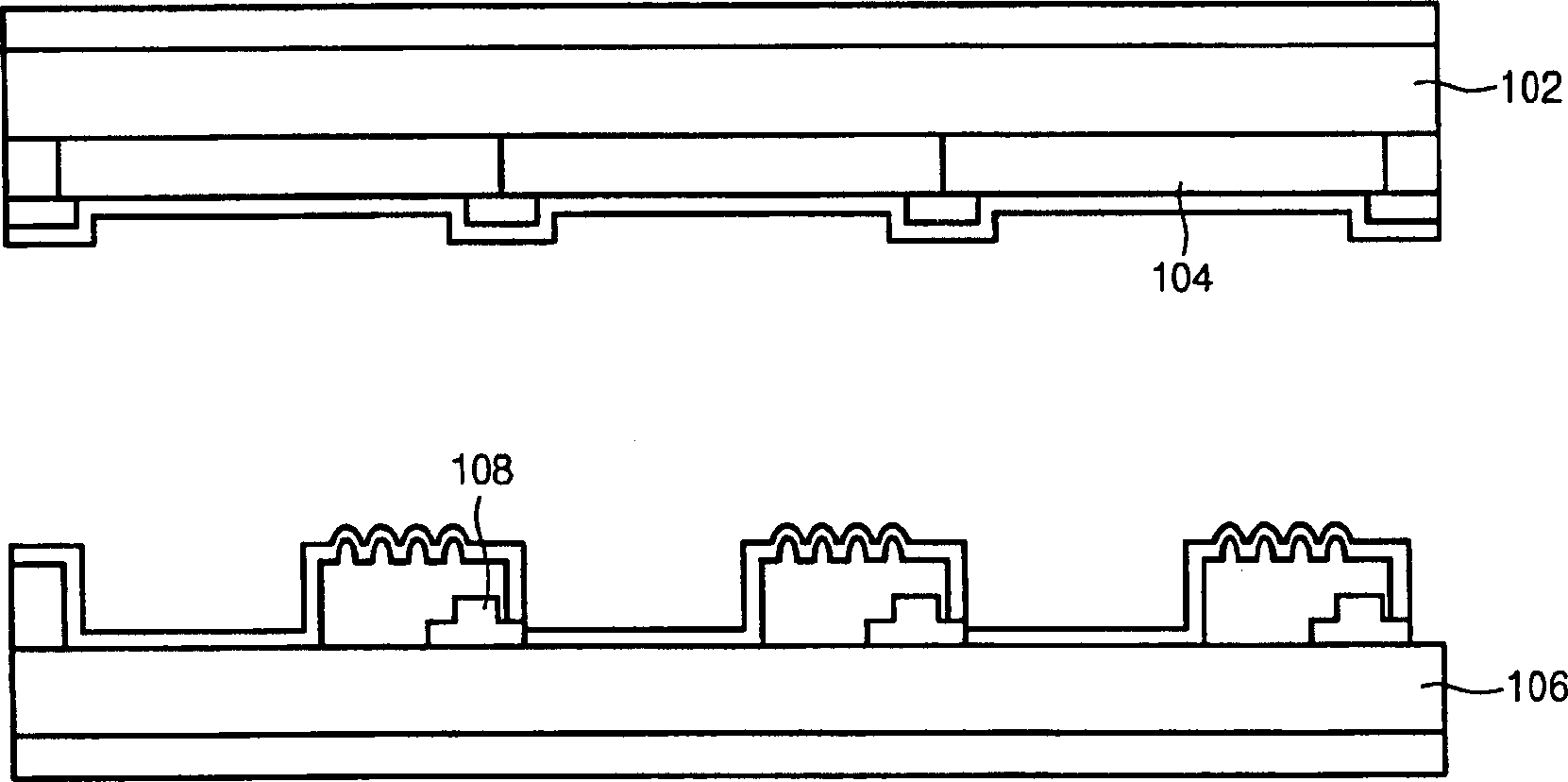

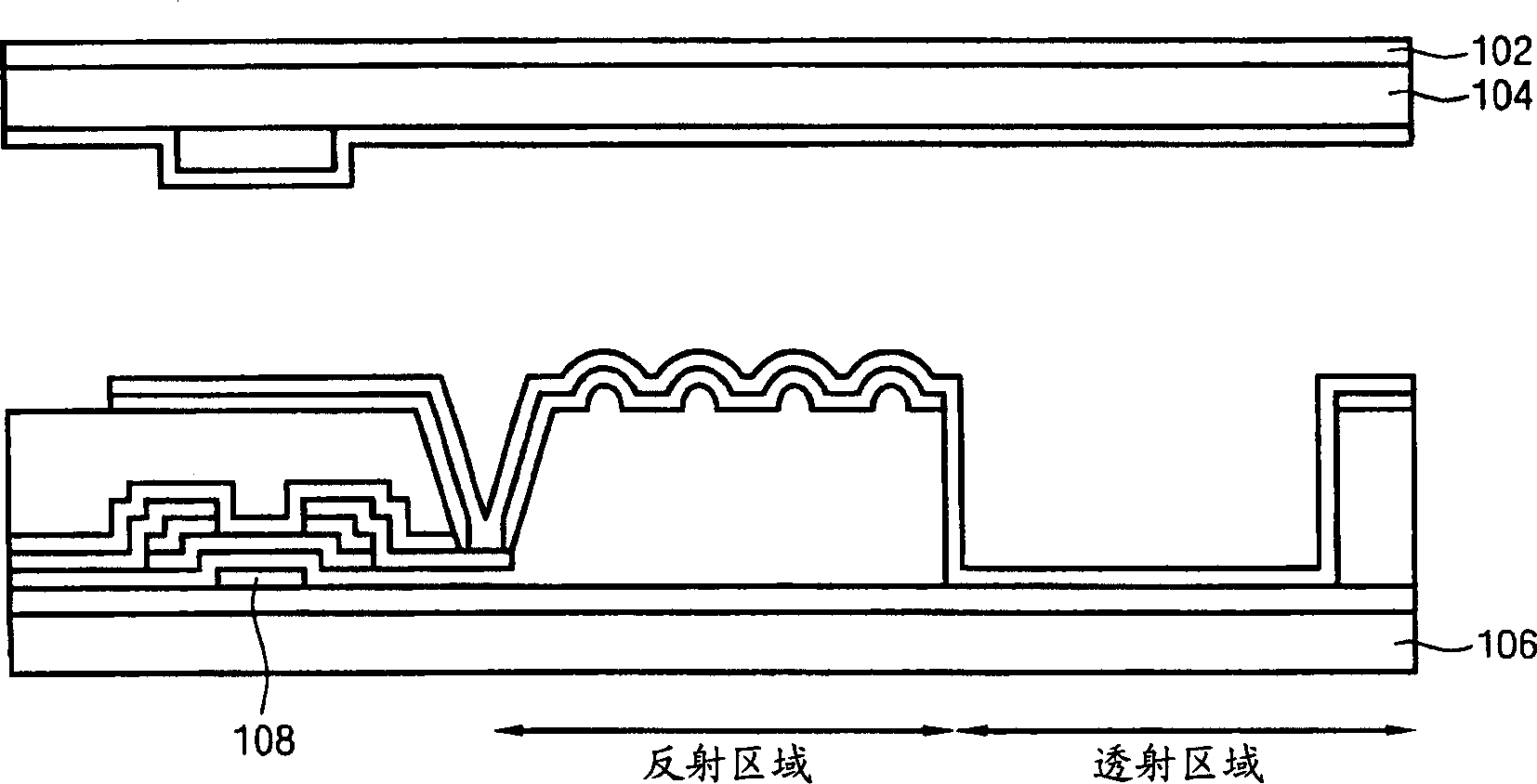

[0019] image 3 is a cross-sectional view showing a transflective liquid crystal display device according to an example of the present invention. Figure 4 is a cross-sectional view showing a transflective liquid crystal cell according to an example of the present invention.

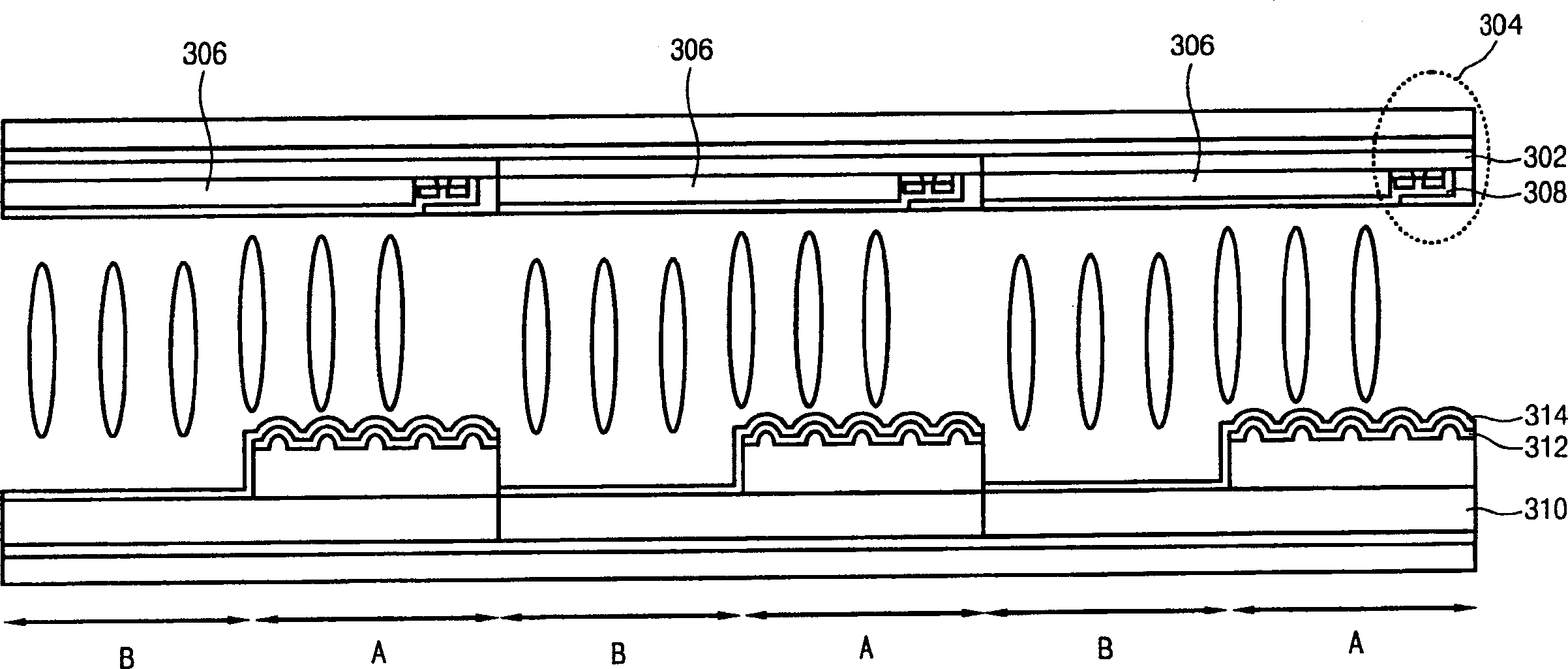

[0020] The transflective liquid crystal display device of the embodiment of the present invention includes: an upper substrate 302, a thin film transistor 304, R, G, B color filters 306, a light-shielding film 308, a lower substrate 310 with a reflective portion A and a transmissive portion B, and a reflective plate 312 and transparent electrode 314.

[0021] Refer below image 3 and Figure 4 A method for manufacturing a transflective liquid crystal display device according to an embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com