Annealing-free driving bridge shell hydraulic forming method using high-strength welded pipe

A hydroforming, high-strength technology, applied in the field of auto parts manufacturing, can solve the problems of high-strength steel elongation not greater than 25%, and achieve the effects of reasonable wall thickness distribution, reducing tonnage, and eliminating the problem of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The hydroforming method of the drive axle case using high-strength welded pipe and no need for annealing in the present invention will be further described in detail below through specific examples.

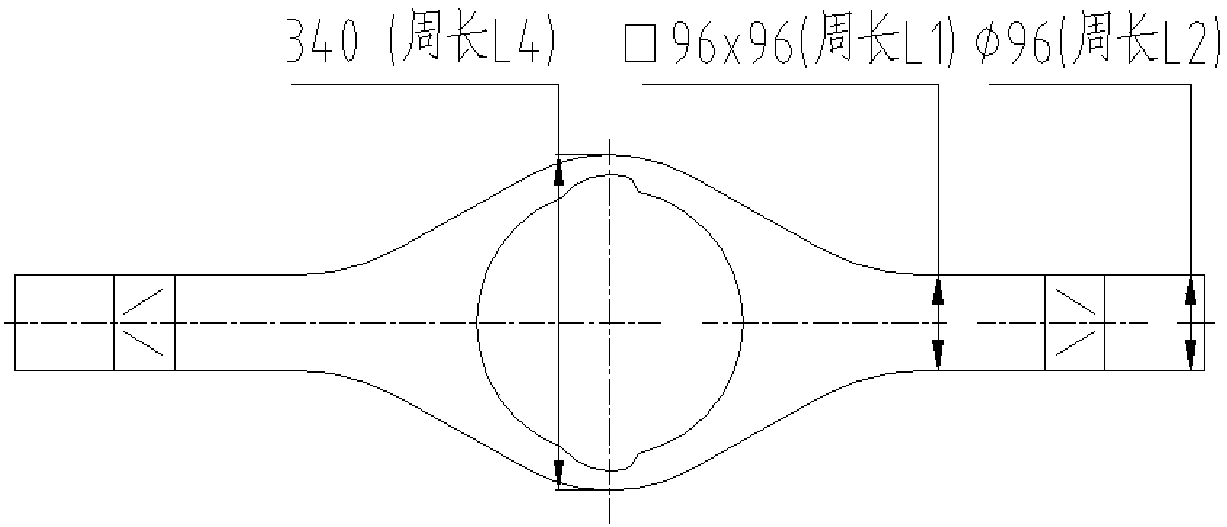

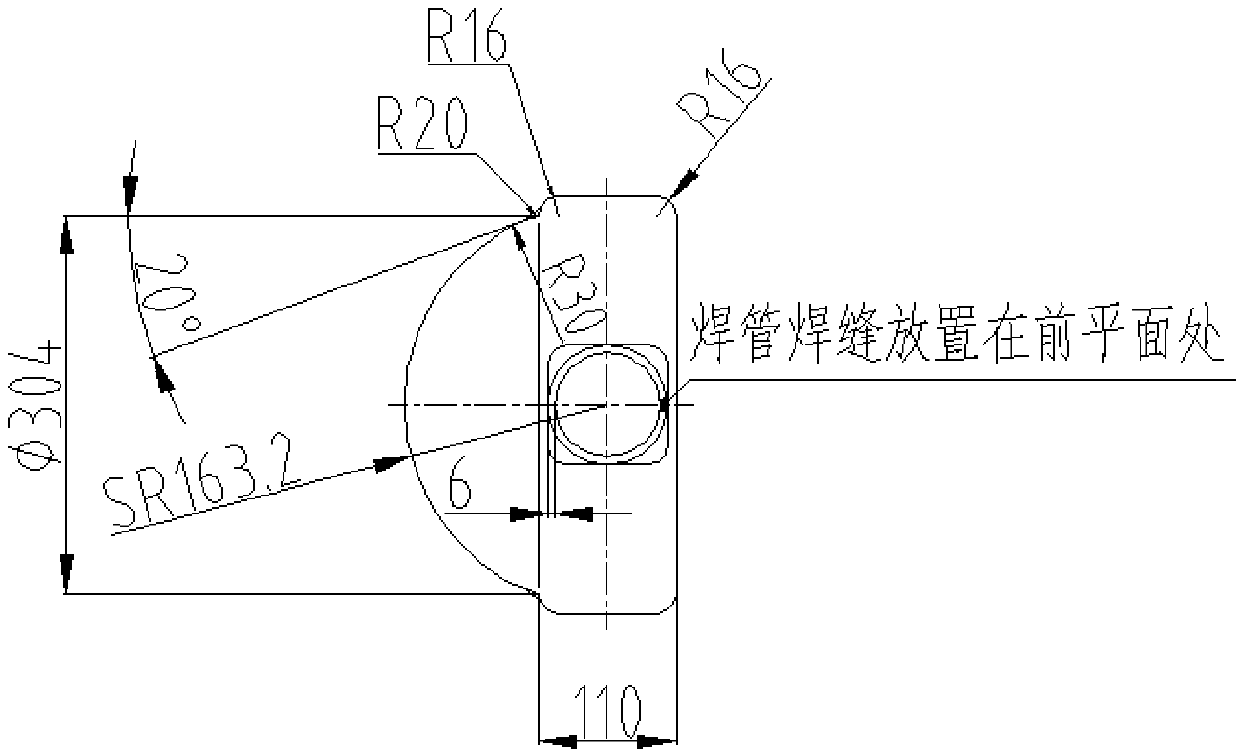

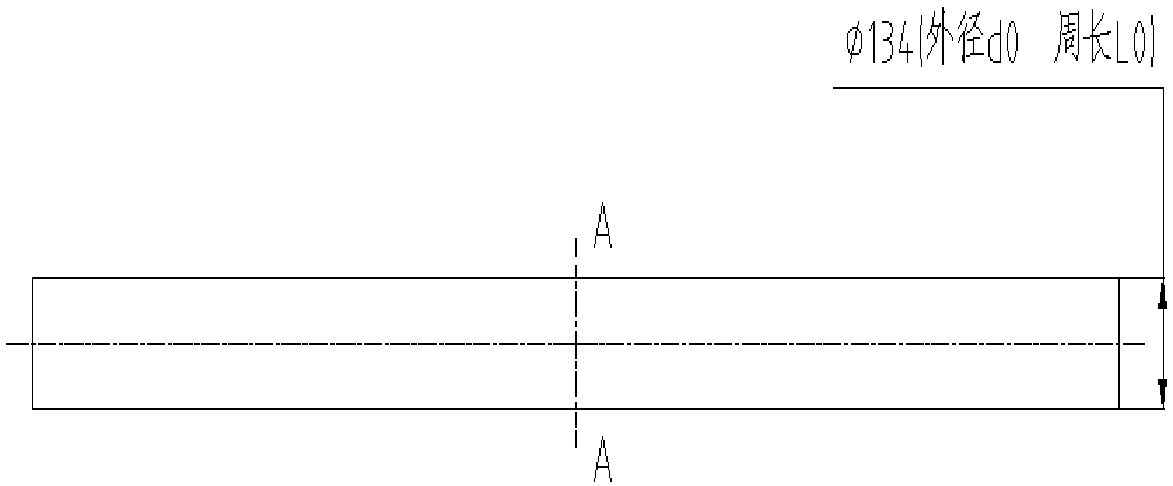

[0070] figure 1 -2 shows a schematic diagram of a 3.5-ton light truck axle housing according to the embodiment of the present invention. Its main shape parameters include: wall thickness 6mm, middle section height of the bridge package L4 is 340mm, rear cover height SR163.2, square section on both sides of the bridge package The size is □L1×L196×96mm, the outer diameter of the round section at both ends of the axle housing is φ96mm, and the transition fillets of the bridge package are R16, R 20, etc. figure 2 The middle welded pipe weld 001 is placed at the front plane.

[0071] Figure 15 , 16 It is a structural schematic diagram of the first hydraulic bulging die of the embodiment of the present invention. The mold body consists of a sliding die 11, a spring assembl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com