Sandwich composite pipe and rapid forming method thereof

A composite material and molding method technology, which is applied in the direction of chemical instruments and methods, synthetic resin layered products, slender components, etc., can solve the problems of high quality of composite material pipe fittings, limited application range of pipe fittings, and cumbersome operation of molding methods, etc. Achieve the effects of shortening the production cycle, facilitating mass production, and facilitating promotion and implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0060] Taking bamboo boards as an example, the manufacturing process of outline bamboo boards is as follows:

[0061] 1) Select the bamboo board with the required interlayer thickness and cut it into bamboo strips with a width of 15mm. The length is determined by the length of the product. For products with a length of more than 2m, it can be spliced by two or more bamboo strips.

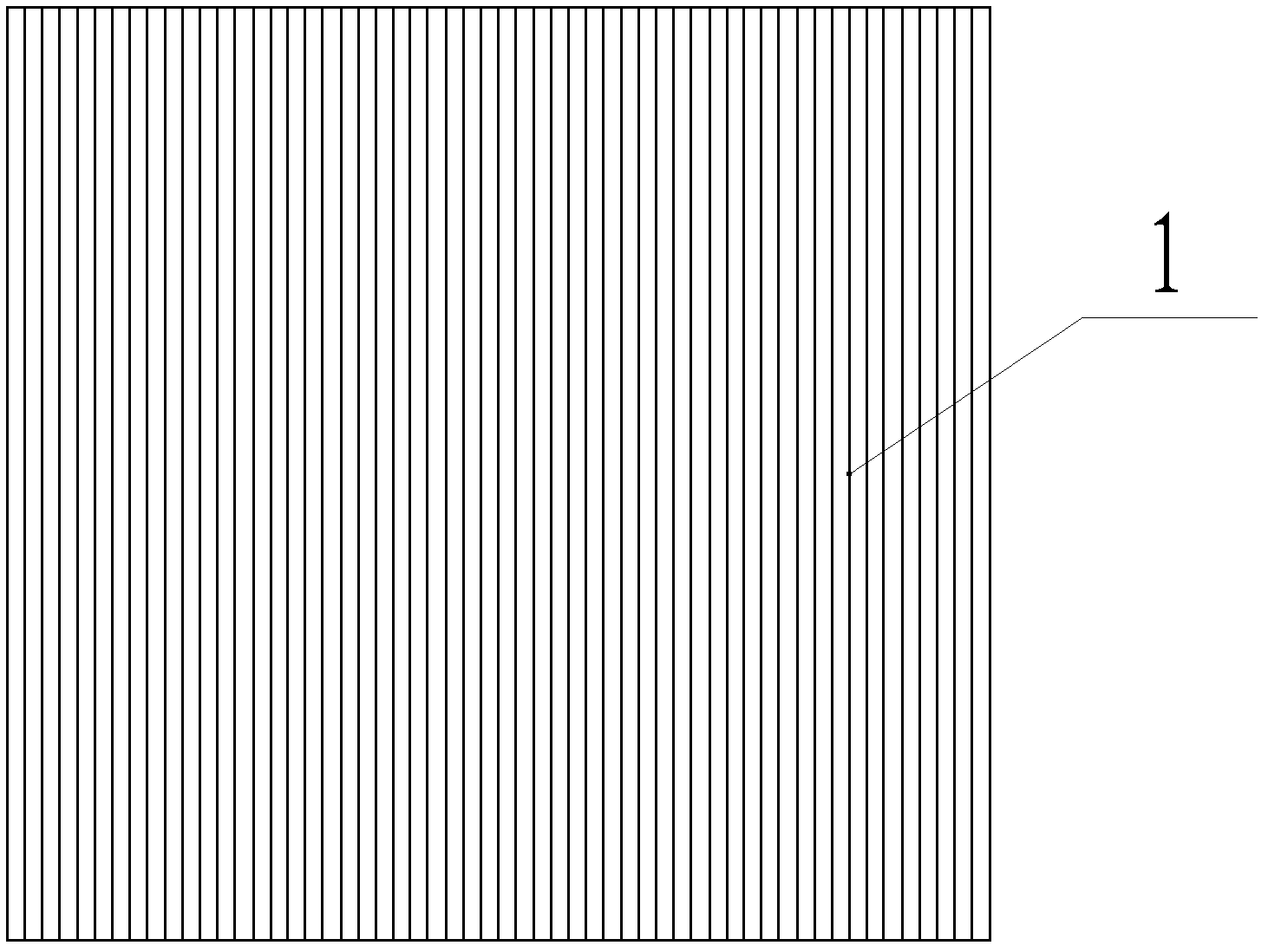

[0062] 2) If the pipe fitting is a round pipe product, the profile plate is expanded into a rectangular plate, and the diameter d of the round pipe is calculated by the formula πd to calculate the width of the rectangular plate, select the number of corresponding bamboo strips, and place the bamboo strips side by side on the platform , use a 50mm wide adhesive fiber tape to bond the upper surface of multiple bamboo strips, and connect multiple bamboo strips into a row to form a rectangular profile board.

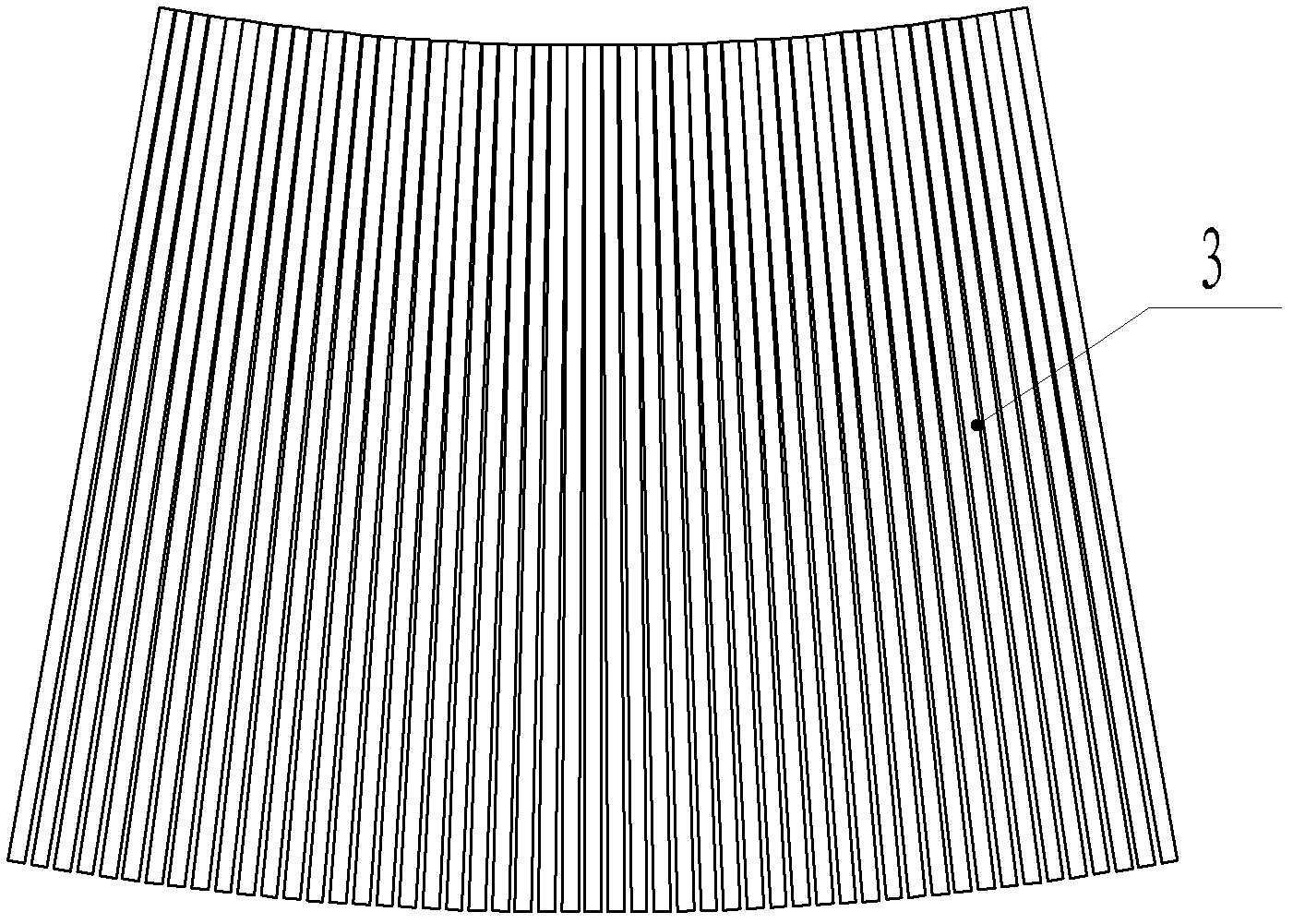

[0063] If the pipe fitting is a tapered product, the profile plate is expanded into a fan-sh...

example 2

[0072] The molding method of the sandwich composite material pipe is basically the same as that of Example 1, and will not be repeated here.

[0073] The differences are:

[0074] The mixing ratio of vinyl resin glue is: 100 parts of vinyl resin glue, 3 parts of curing agent, and 1.5 parts of accelerator;

[0075] The profile board made of several strips of balsa wood is used as the sandwich layer, and the tapered tube formed by the fan-shaped surface is taken as an example. The specific molding steps are as follows: First, on the mold coated with the release agent, use a plastic film to be evenly wound from one end of the mold to the other end of the mold. The lap width of the plastic film should be 25mm; after wrapping the inner skin, Cover the fan-shaped balsa wood profile boards cut according to size directly on the surface of the inner skin, use 10mm thick adhesive fiber tape to bond the joints, use a brush to seal the gaps between the balsa wood profile boards with viny...

example 3

[0078] The molding method of the sandwich composite material pipe is basically the same as that of Example 1, and will not be repeated here.

[0079] The differences are:

[0080] The mixing ratio of vinyl resin glue is: 95 parts of vinyl resin glue, 2 parts of curing agent, and 0.8 parts of accelerator;

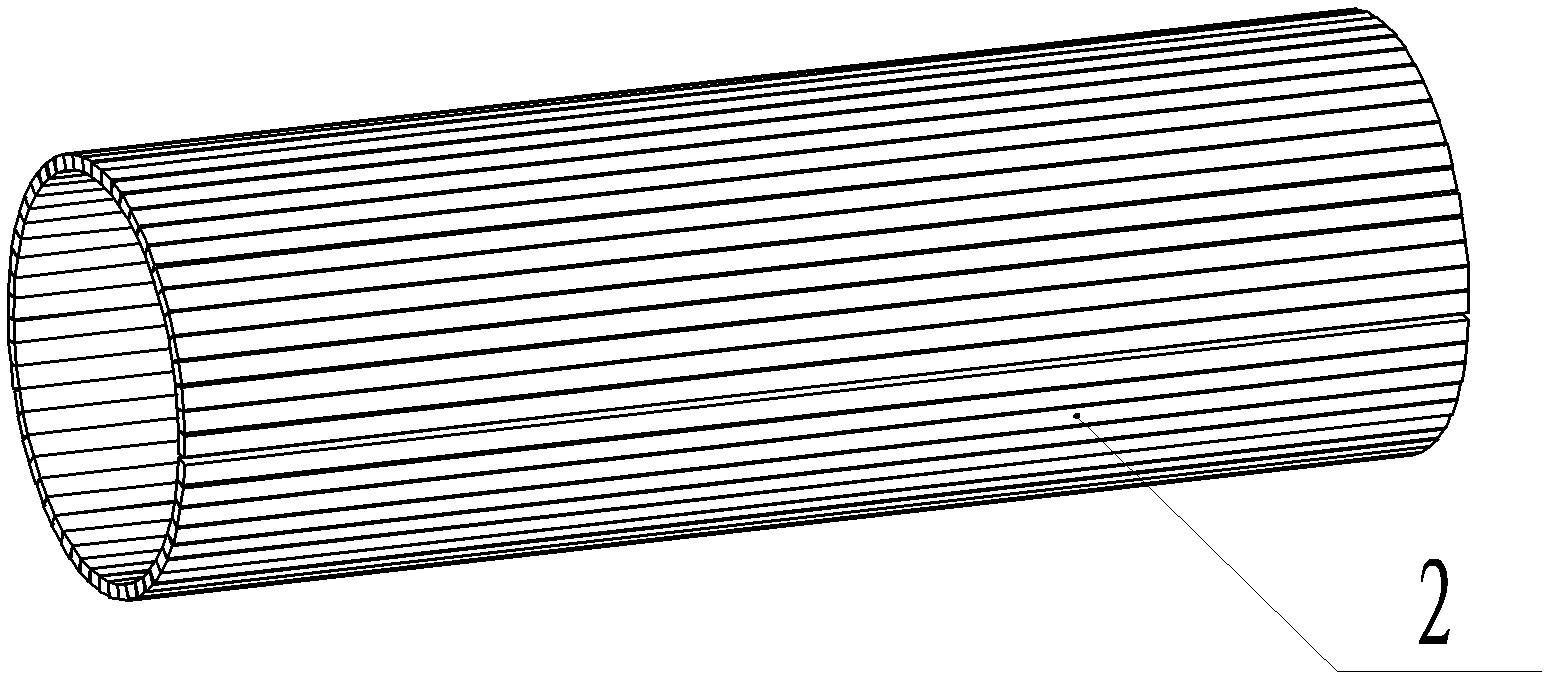

[0081] The profile plate made of pultruded rods is used as the sandwich layer, and the specific forming steps are as follows:

[0082] 1) Select an epoxy resin pultruded rod with an outer diameter of 10mm and a wall thickness of 3mm, calculate the expanded rectangular width of the pultruded rod profile plate according to the diameter of the product, select the number of corresponding pultruded rods, and place the pultruded rods side by side On the platform, use a steel ruler to vertically draw the pultrusion rod and draw a line after pressing it tightly. Use a diameter of 2 ~ Drill holes with a 3mm drill bit, and use glass fiber roving to penetrate and sew into a pultruded r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com