Cu-Mn alloy sputtering target and semiconductor wiring

A technology for sputtering targets and semiconductors, which is applied in semiconductor devices, semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, etc., can solve problems such as unclear mutual relations, contamination of Si substrates, and unreliable barrier films, etc., to achieve improved Anti-electromigration (EM), simplification of film formation process, and effects of pollution prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

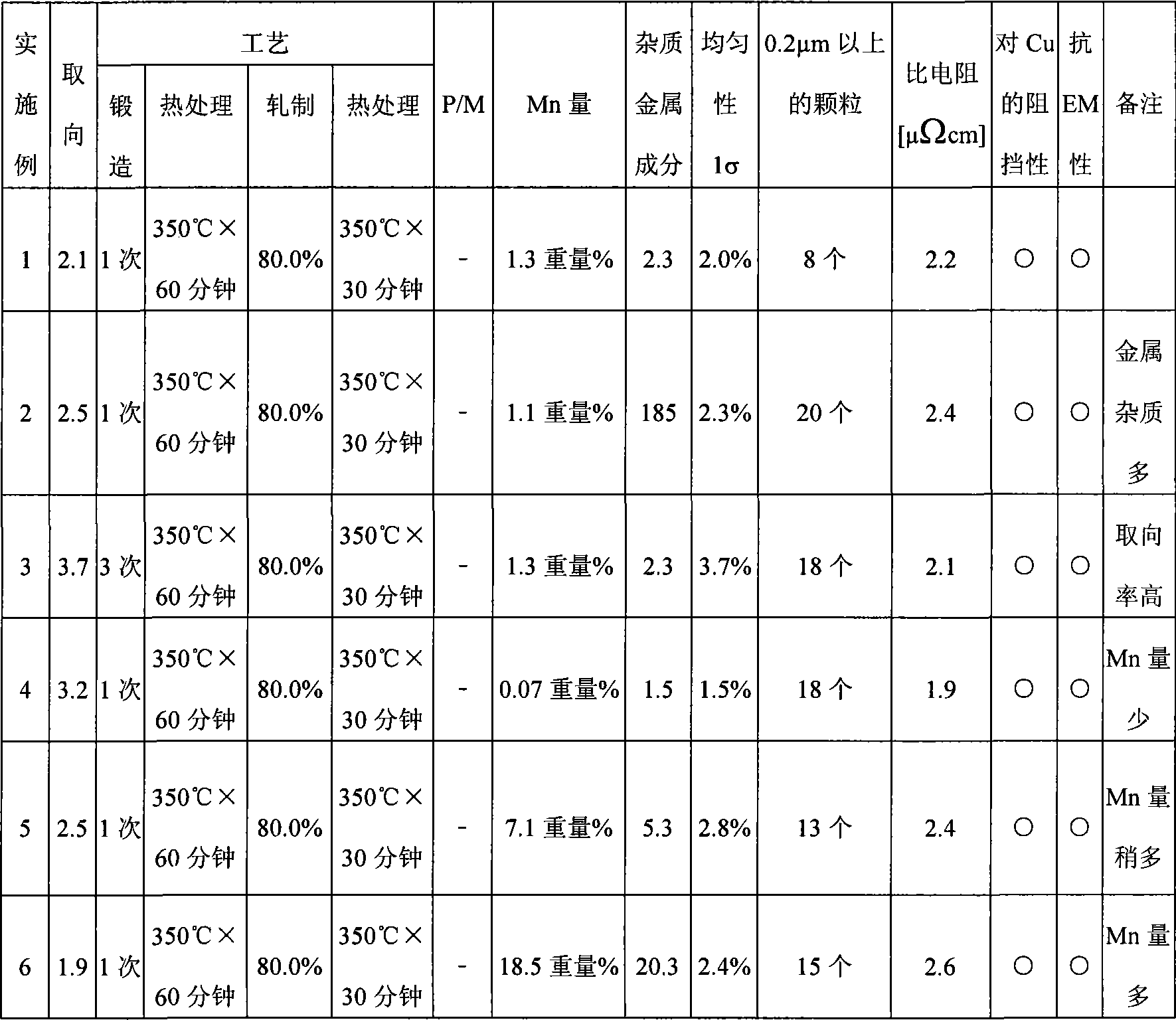

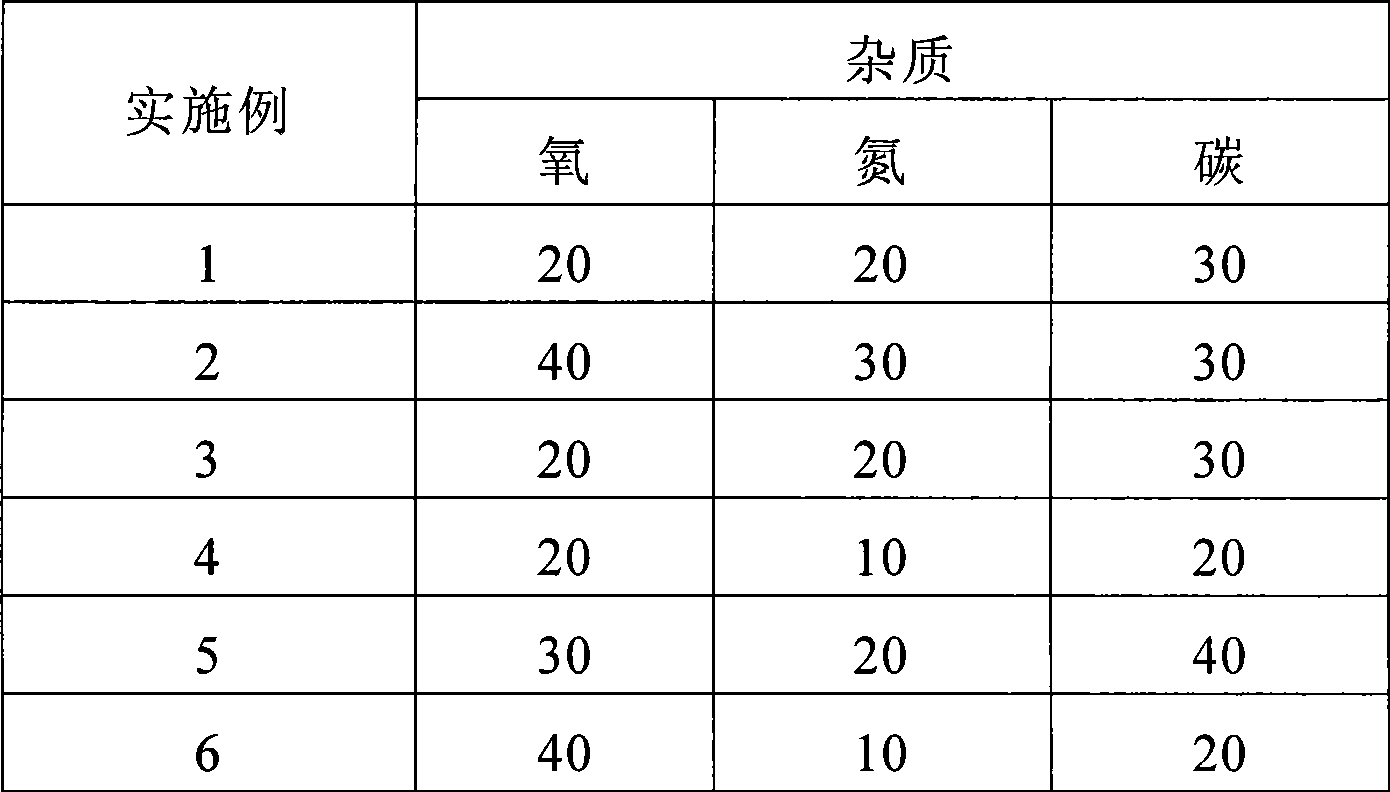

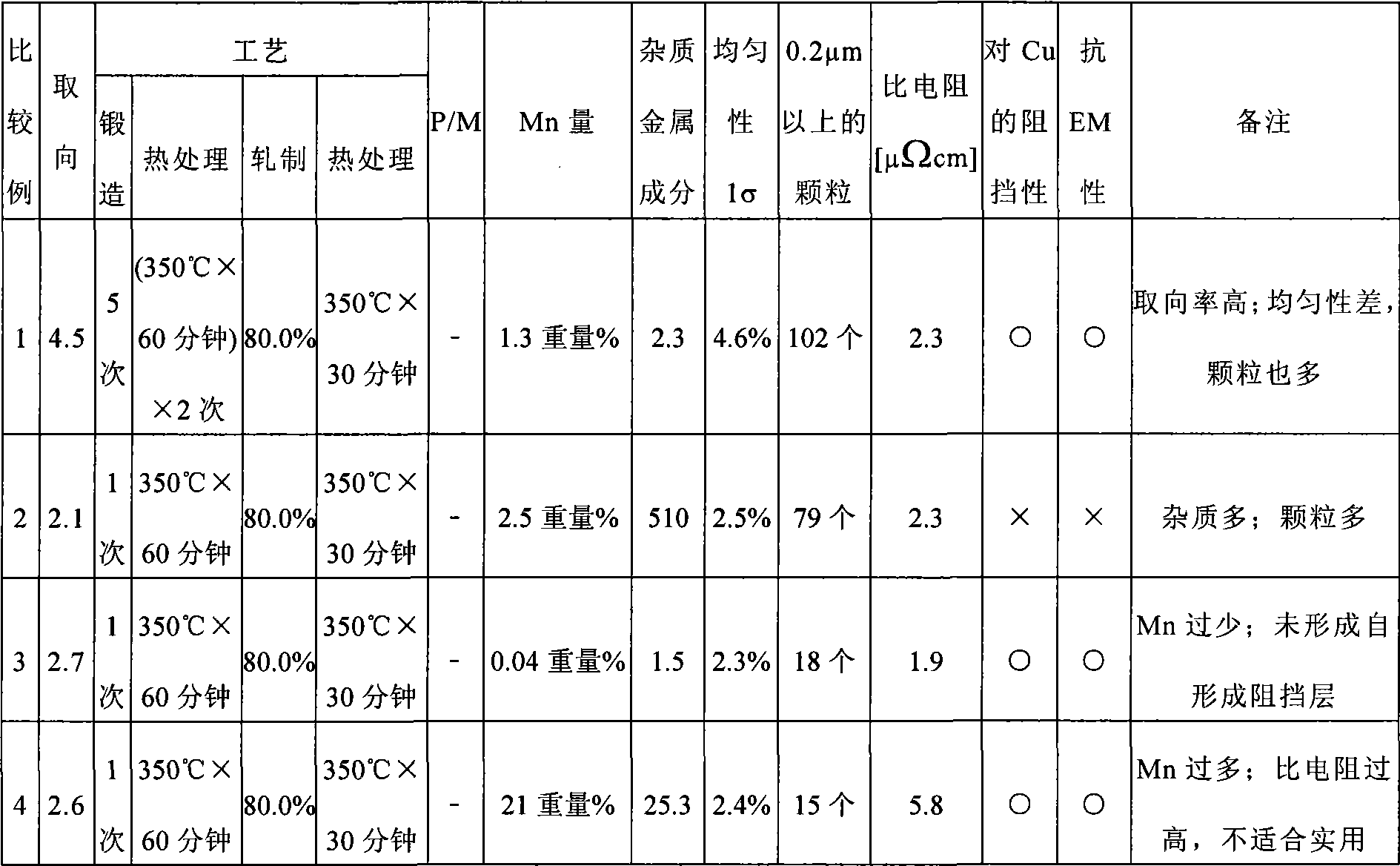

[0078] Prepare high-purity copper (Cu) with a purity of 6N or higher and manganese (Mn) with a level of 5N, and use a high-purity graphite crucible to melt in a high-vacuum atmosphere to obtain a high-purity alloy. Table 1 shows the alloy compositions of Examples 1 to 6 produced.

[0079] The alloyed molten metal is cast into a water-cooled copper mold under a high vacuum atmosphere to obtain an ingot. Next, after removing the surface layer of the produced ingot and making it into φ85×100h, it was heated to 350°C, and then directly hot forged (first forging) into φ105×65h, and then hot rolled in the next step. Among them, the following operations are only performed on Example 3: hot forging (first forging) to φ105×65h, then reheating to 350°C, radial forging (second forging) to φ85×100h, and further Its hot heading forging (the third forging) is φ105×65h. The number of times of forging is arbitrary. Next, hot rolling was performed at 400° C. to φ200×18 t, and further cold r...

Embodiment 1

[0090] (Film characteristics and evaluation of Example 1)

[0091] Example 1 contained 1.3% by weight of Mn, and the total amount of Be, B, Mg, Al, Si, Ca, Ba, La, and Ce was 2.3 ppm by weight. The manufacturing conditions of the target are shown in Table 1. The results are shown in Table 1. When the copper alloy wiring and seed layer for semiconductors are made, the Cu diffusion resistance (barrier property) is excellent, and all show good anti-EM characteristics (almost no disconnection) and film Resistance (low resistance: 2.2 μΩcm). This is because manganese diffuses to the upper part, the side surface, and the lower part of the wiring to form a good barrier film, and at the same time, the resistance of the central part of the wiring is lowered. In addition, almost no disconnection was observed, which is considered to be because the total amount of Be, B, Mg, Al, Si, Ca, Ba, La, and Ce was reduced to 2.3 wtppm.

[0092] In this Example 1, as the structure of the Cu-Mn a...

Embodiment 2

[0096] (Film characteristics and evaluation of Example 2)

[0097] Example 2 contained 1.1% by weight of Mn, and the total amount of Be, B, Mg, Al, Si, Ca, Ba, La, and Ce was 185 ppm by weight. The manufacturing conditions of the target are shown in Table 1. The results are shown in Table 1. When the copper alloy wiring and seed layer for semiconductors are made, the Cu diffusion resistance (barrier property) is excellent, and all show good anti-EM characteristics (almost no disconnection) and film Resistance (low resistance: 2.4 μΩcm). This is because manganese diffuses to the upper part, the side surface, and the lower part of the wiring to form a good barrier film, and at the same time, the resistance of the central part of the wiring is lowered. In addition, almost no disconnection is observed, which is considered to be because the total amount of Be, B, Mg, Al, Si, Ca, Ba, La, and Ce is 185 ppm by weight, which is within the condition range of the present invention. Ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com