Sputtering target and manufacturing method therefor

A manufacturing method and sputtering target technology, which are applied in sputtering coating, semiconductor/solid-state device manufacturing, ion implantation plating, etc., to achieve the effects of excellent corrosion resistance, pollution prevention, and deformation suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

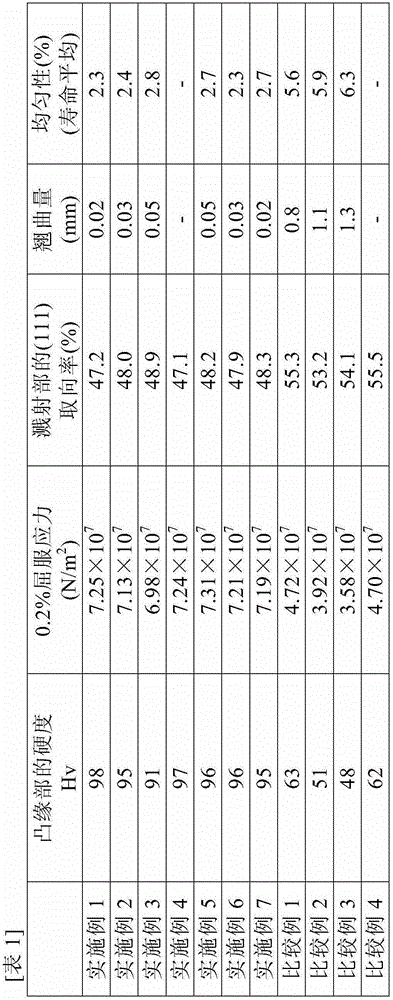

Embodiment 1

[0039] In Example 1, the Cu-Mn alloy (Mn1wt%) ingot obtained by melting and casting was forged and rolled to produce a rolled plate, and the outer peripheral portion (corresponding to the flange portion) of the rolled plate was further forging. Next, heat treatment is performed on this, and then quenched to obtain a target raw material. Then, a backing plate-integrated sputtering target with a diameter of 540 mm and a thickness of 25 mm was produced by machining. The physical properties of this target were evaluated. As a result, the Vickers hardness Hv of the flange was 98, and the 0.2% yield stress of the flange was 7.25×10 7 N / m 2 , the (111) orientation rate of the sputtered surface is 47.2%.

Embodiment 2

[0041] In Example 2, the Cu-Mn alloy (Mn1wt%) ingot obtained by melting and casting was forged and rolled to produce a rolled plate, and the outer peripheral portion (corresponding to the flange portion) of the rolled plate was further processed. forging. Next, heat treatment is performed on this, and then quenched to obtain a target raw material. Then, a backing plate-integrated sputtering target with a diameter of 540 mm and a thickness of 25 mm was produced by machining. The physical properties of this target were evaluated. As a result, the Vickers hardness Hv of the flange was 95, and the 0.2% yield stress of the flange was 7.13×10 7 N / m 2 , the (111) orientation rate of the sputtered surface is 48.0%.

Embodiment 3

[0043] In Example 3, the Cu-Mn alloy (Mn1wt%) ingot obtained by melting and casting was forged and rolled to produce a rolled plate, and the outer peripheral portion (corresponding to the flange portion) of the rolled plate was further forging. Next, heat treatment is performed on this, and then quenched to obtain a target raw material. Then, a backing plate-integrated sputtering target with a diameter of 540 mm and a thickness of 25 mm was produced by machining. The physical properties of this target were evaluated. As a result, the Vickers hardness Hv of the flange was 91, and the 0.2% yield stress of the flange was 6.98×10 7 N / m 2 , the (111) orientation rate of the sputtered surface is 48.9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| orientation degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com