Organic electroluminescent element

An electroluminescent element and luminescent technology, applied in the direction of electroluminescent light source, electrical components, electric light source, etc., can solve the problems of quenching luminescence, complicated process, and increase of product manufacturing cost, and achieve simple and simplified forming process Manufacturing process, the effect of reducing the number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

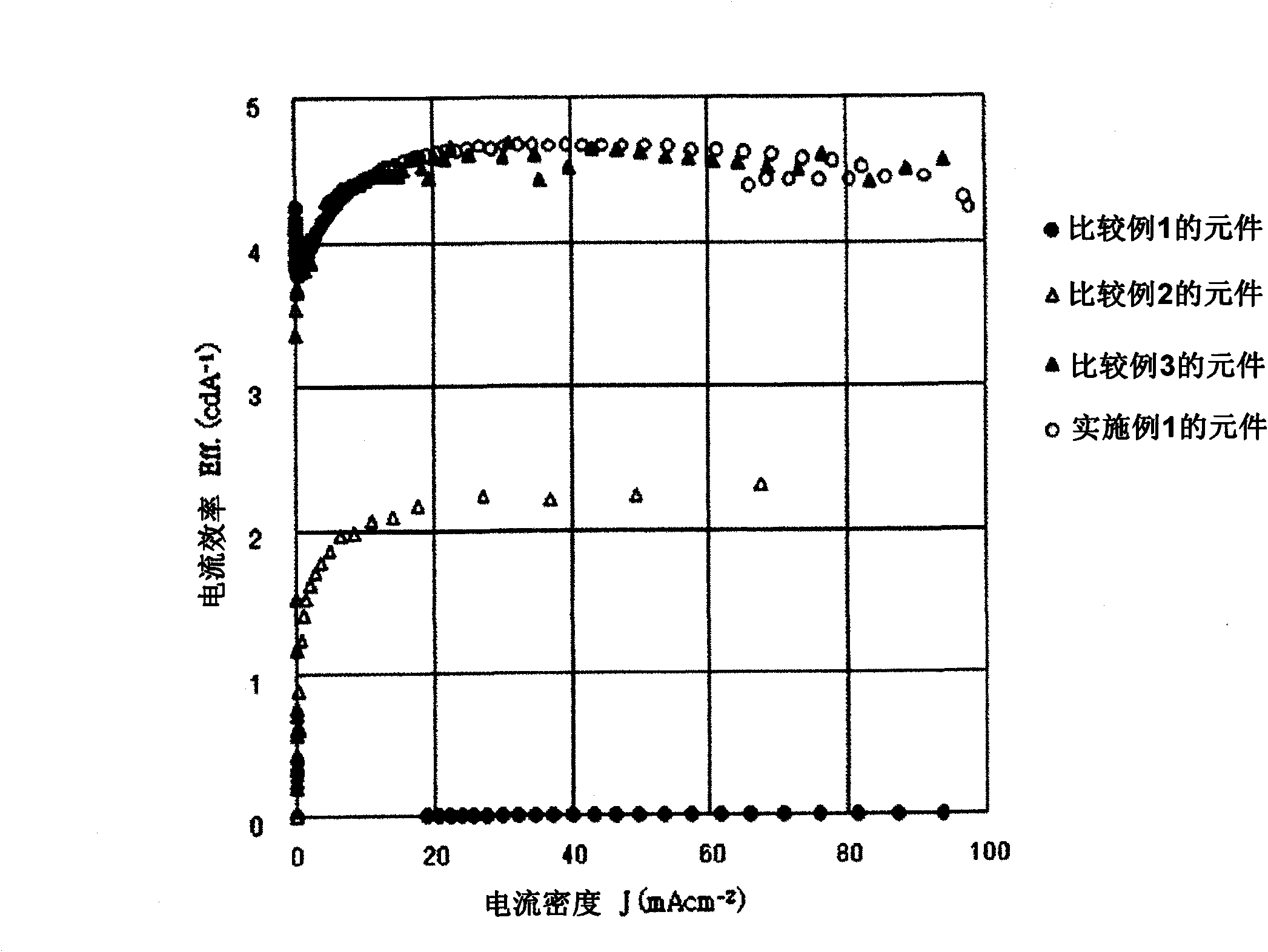

Embodiment 1

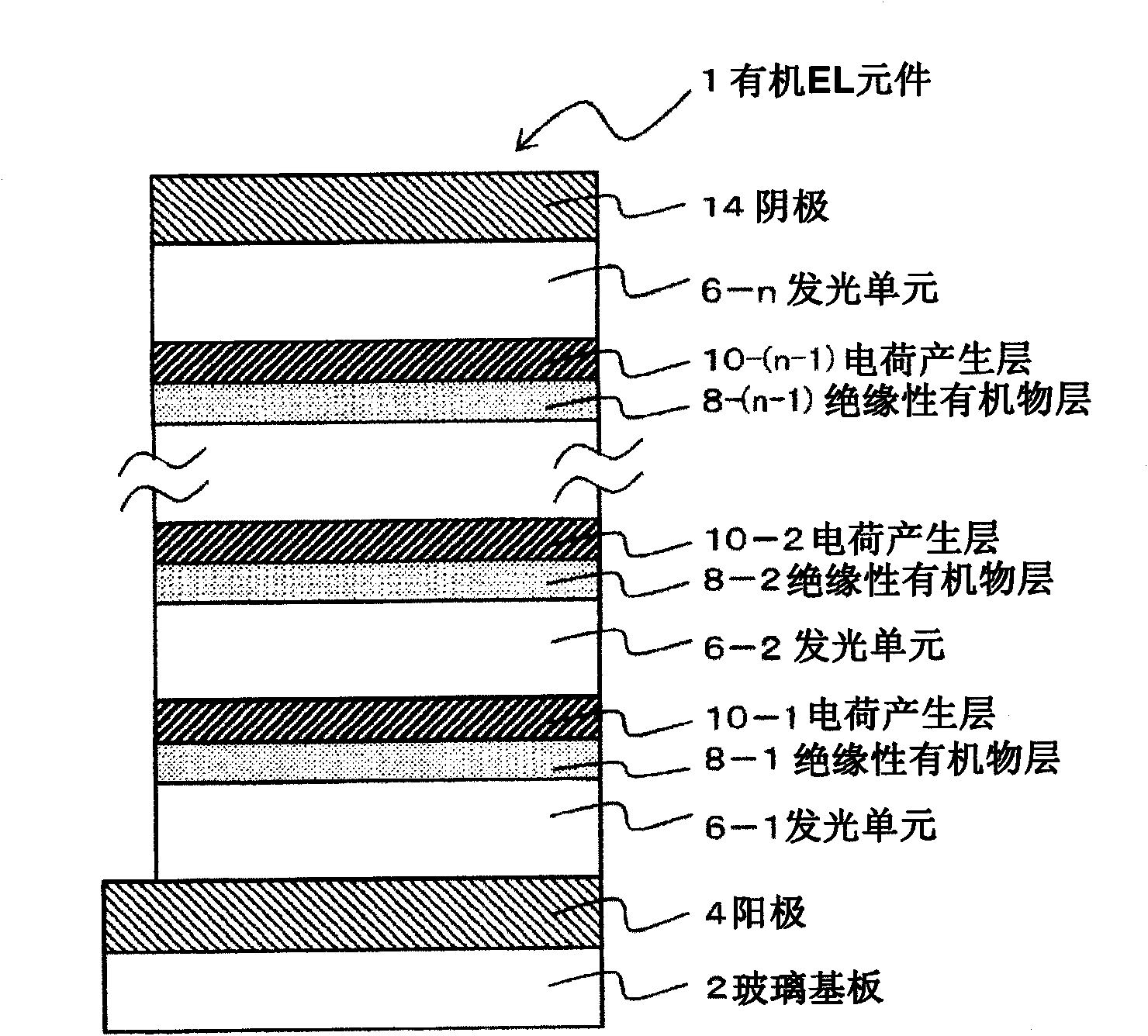

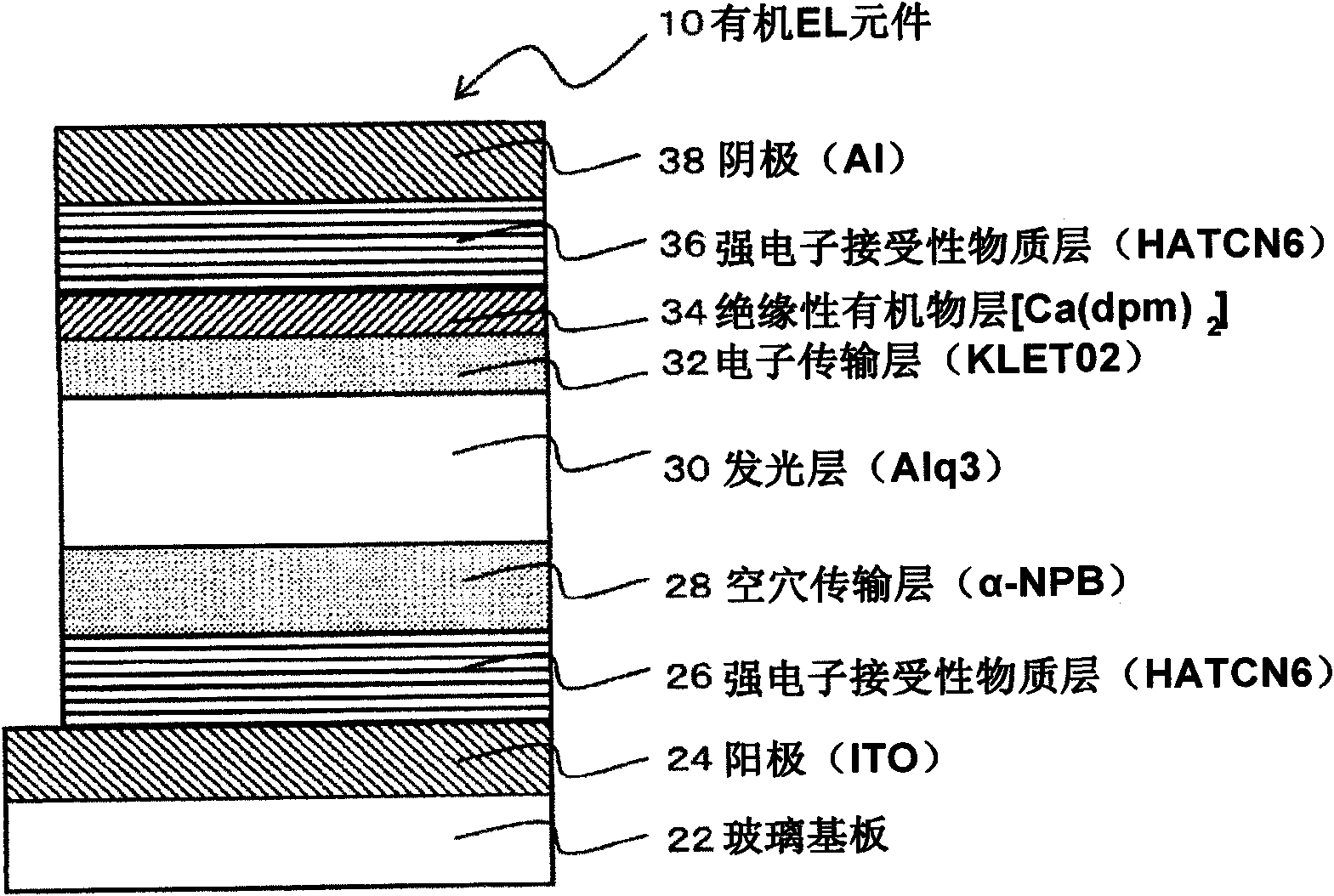

[0159] As the organic EL element of Example 1, the layer described below was sequentially stacked, which had figure 1 An organic EL element 1 of the structure shown. The constituent materials and thickness of each layer are as follows.

[0160] 1) Anode

[0161] ITO (Indium Tin Oxide), 800 Angstroms

[0162] 2) Strong electron-accepting material layer

[0163] HATCN6 (hexaazatriphenylene derivative), 200 Angstroms

[0164] 3) Hole transport layer

[0165] NPB{4,4′-bis[N-(2-naphthyl)-N-anilino]biphenyl}, 500 Angstroms

[0166] 4) Light-emitting layer

[0167] Alq3 [tris(8-hydroxyquinoline) aluminum complex], 300 Angstroms

[0168] 5) Electron transport layer

[0169] KLET02 manufactured by CHEMIPRO KASEI KAISHA, LTD., Japan, 250 Angstroms

[0170] 6) Insulating organic layer

[0171] Ca(dpm) 2 [bis(2,2,6,6-tetramethyl-3,5-heptanedionate) calcium], 60 Angstroms

[0172] 7) Strong electron-accepting material layer

[0173] HATCN6 (hexaazatriphenylene derivative), 200...

Embodiment 2

[0225] As the organic EL element of Example 2, an organic EL element having a structure in which the layers described below were sequentially laminated on a glass substrate was produced.

[0226] 1) Anode

[0227] ITO (Indium Tin Oxide), 800 Angstroms

[0228] 2) Strong electron-accepting material layer

[0229] HATCN6 (hexaazatriphenylene derivative), 200 Angstroms

[0230] 3) Hole transport layer

[0231] NPB{4,4′-bis[N-(2-naphthyl)-N-anilino]biphenyl}, 500 Angstroms

[0232] 4) Light-emitting layer

[0233] Alq3 [tris(8-hydroxyquinoline) aluminum complex], 200 Angstroms

[0234] 5) Electron transport layer

[0235] KLET02 manufactured by CHEMIPRO KASEI KAISHA, LTD., Japan, 250 Angstroms

[0236] 6) Insulating organic layer (hole-transporting organic layer, a layer that functions as an insulating layer on the electron-transporting site)

[0237] NPB{4,4′-bis[N-(2-naphthyl)-N-anilino]biphenyl}, 60 Angstroms

[0238] 7) Strong electron-accepting material layer

[023...

Embodiment 3

[0262] As the organic EL element of Example 3, an organic EL element having two light-emitting layers, that is, two light-emitting units, was fabricated by sequentially laminating the layers described below on a glass substrate.

[0263] 1) Anode

[0264] ITO (Indium Tin Oxide), 800 Angstroms

[0265] 2) Strong electron-accepting material layer

[0266] HATCN6 (hexaazatriphenylene derivative), 200 Angstroms

[0267] 3) The hole transport layer of the first light-emitting unit

[0268] NPB{4,4′-bis[N-(2-naphthyl)-N-anilino]biphenyl}, 500 Angstroms

[0269] 4) The light-emitting layer of the first light-emitting unit

[0270] Alq3 [tris(8-hydroxyquinoline) aluminum complex], 200 Angstroms

[0271] 5) The electron transport layer of the first light-emitting unit

[0272] KLET02 manufactured by CHEMIPRO KASEI KAISHA, LTD., Japan, 250 Angstroms

[0273] 6) Insulating organic layer (hole-transporting organic layer, a layer that functions as an insulating layer on the electron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com