Helical blade forming device

A technology for forming and processing helical blades, which is applied in the field of forming and processing devices for helical blades, can solve problems such as poor precision and low production efficiency, and achieve the effects of shortening process time, high processing precision and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

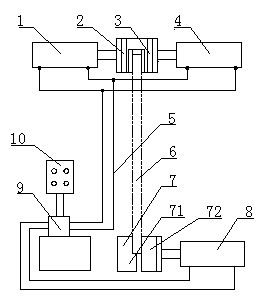

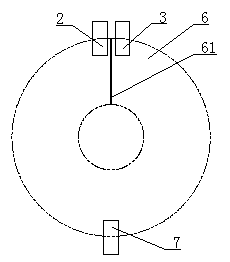

[0008] see Figure 1 to Figure 2 , the present invention comprises a left hydraulic cylinder 1, a left chuck 2, a right chuck 3, a right hydraulic cylinder 4, a lower chuck 7, a lower hydraulic cylinder 8, a hydraulic station 9 and an electric control box 10, and the lower chuck 7 includes Fixed clip 71 and movable clip 72, described left chuck 2 is connected with the extension shaft of left hydraulic cylinder 1, and described right chuck 3 is connected with the extension shaft of right hydraulic cylinder 4, and described movable clip The block 72 is connected with the extension shaft of the lower hydraulic cylinder 8, and the hydraulic station 9 is respectively connected with the left hydraulic cylinder 1, the right hydraulic cylinder 4 and the lower hydraulic cylinder 8 through the oil pipe 5 to form a hydraulic control circuit, and the electric control box 10 It is connected with the hydraulic station 9 by wires to form an electrical control circuit.

[0009] During work, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com