Flexible plate reeling machine with side roller

A technology of a plate rolling machine and a side roller, which is applied in the field of sheet rolling and flexible plate rolling machine, can solve the problems of increasing manufacturing cost and reducing production efficiency, and achieves the effect of improving forming accuracy, high work efficiency and reducing production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

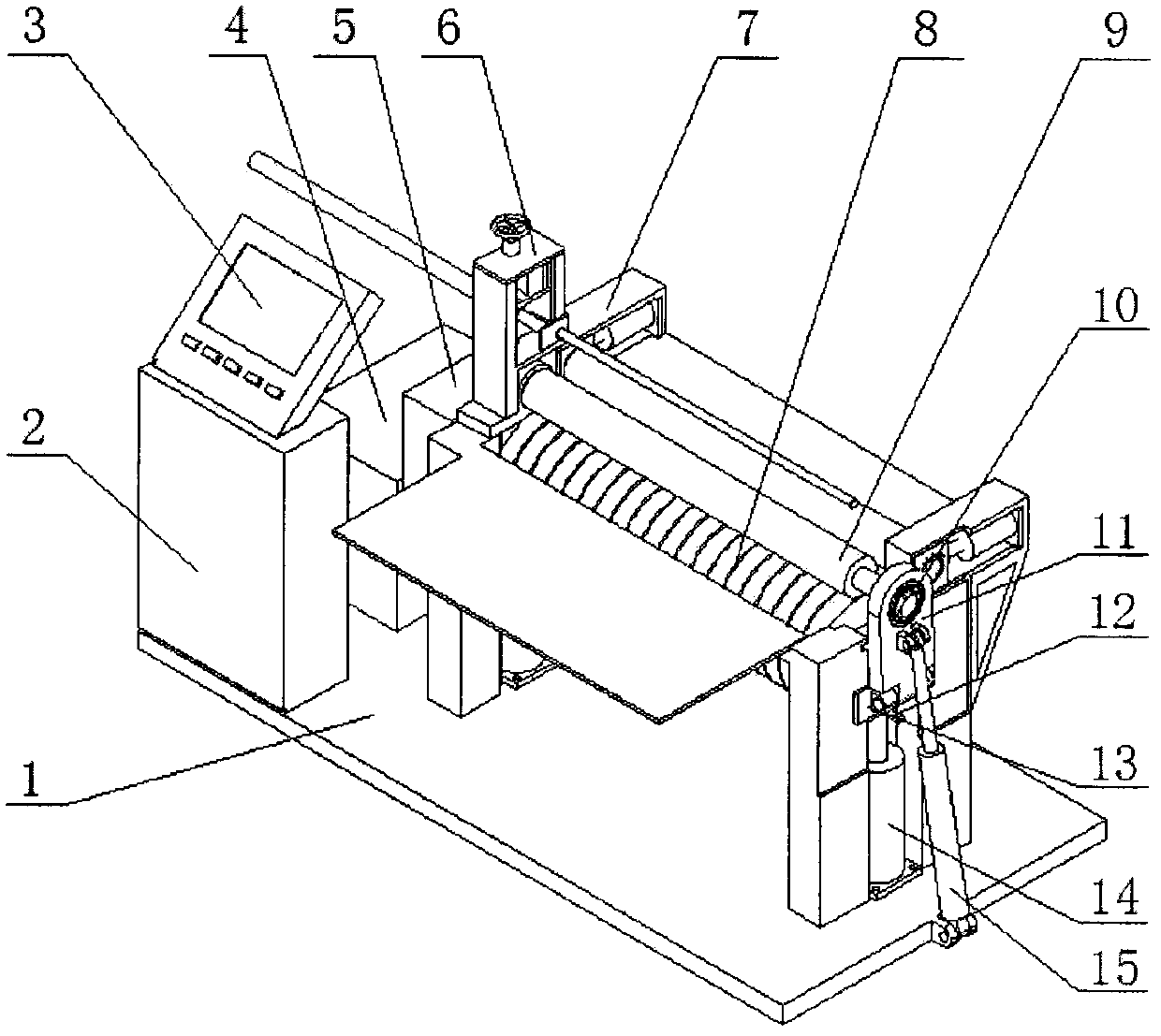

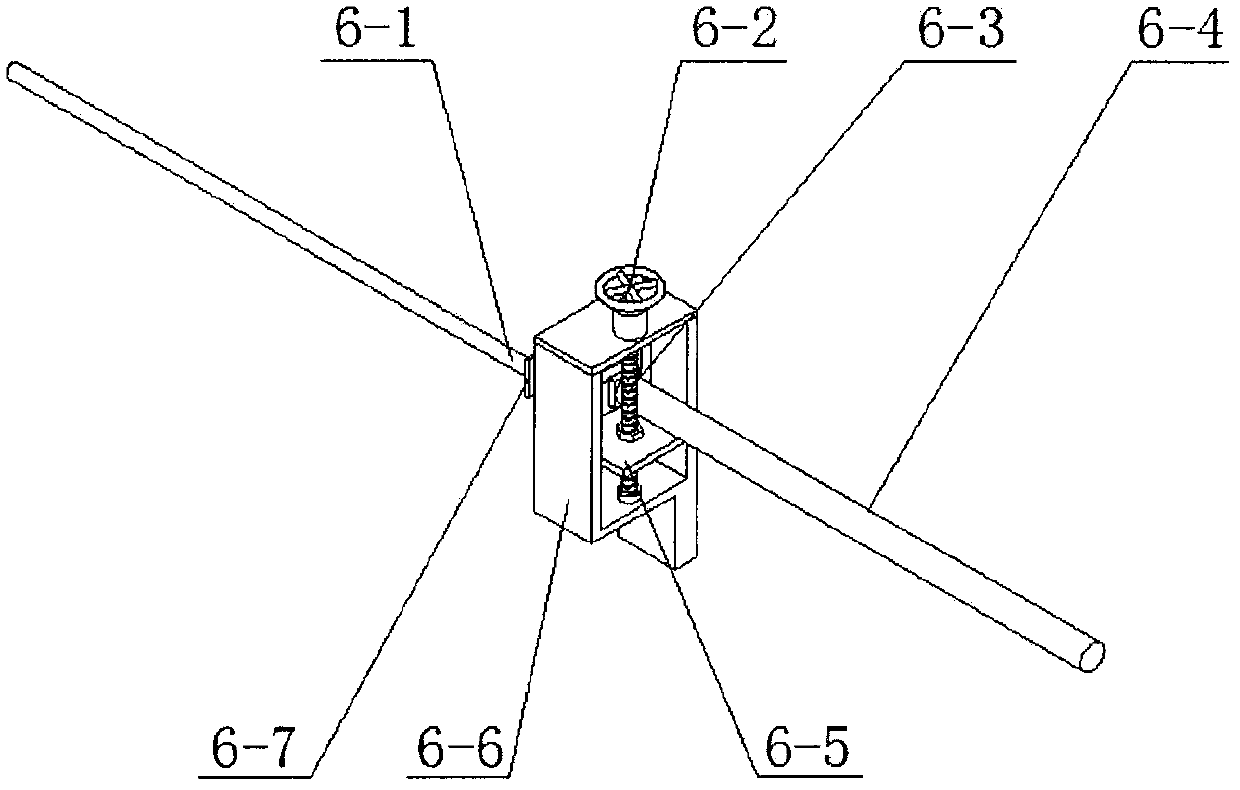

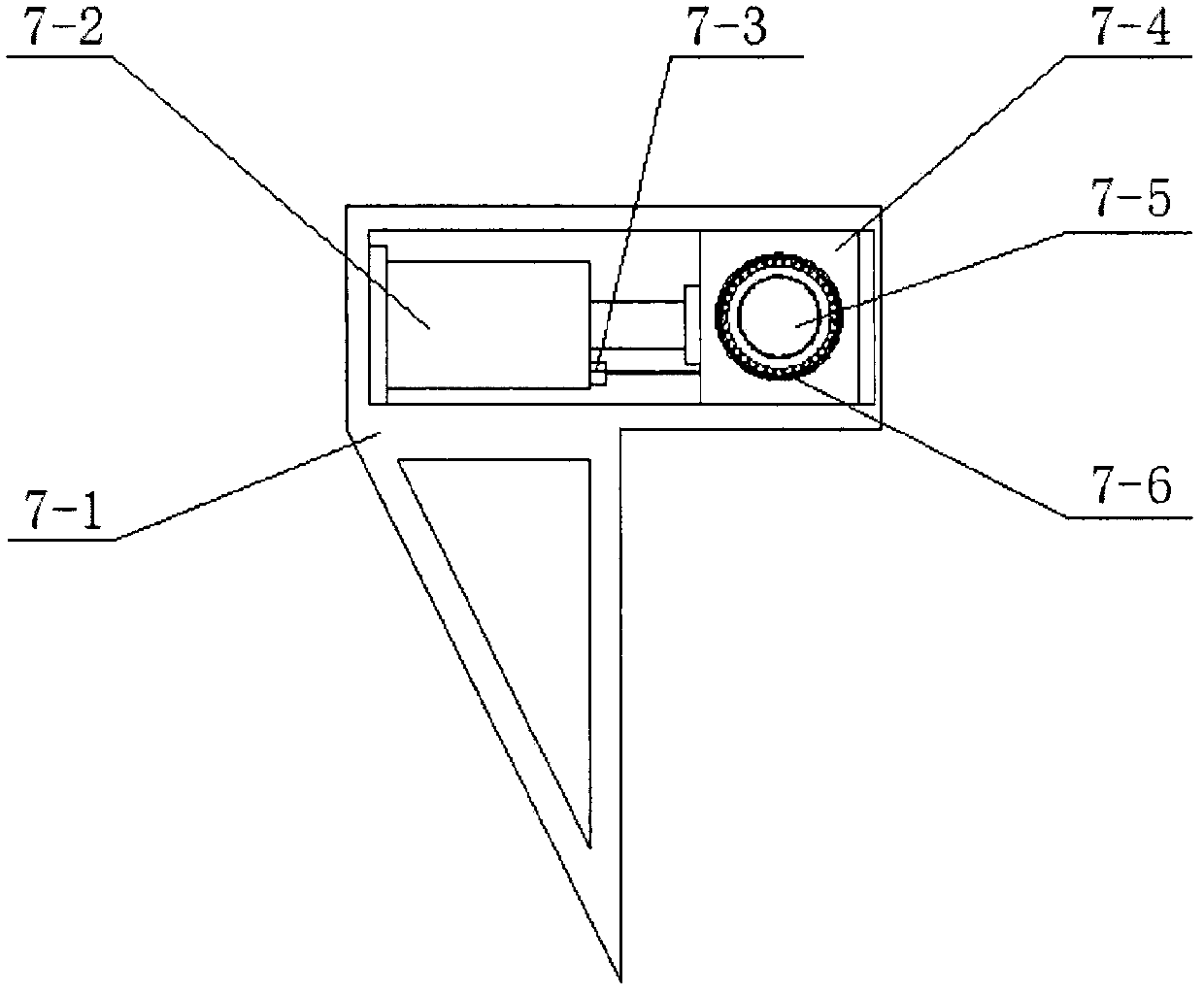

[0019] Such as figure 1 As shown, a flexible plate rolling machine with side rollers consists of body 1, control cabinet 2, operation panel 3, hydraulic station 4, drive motor 5, unloading device 6, side roller device 7, polyurethane rubber roller 8, rigid Roller 9, bearing 10, overturning frame 11, proximity switch 12, bearing pin seat 13, lifting hydraulic device 14, overturning hydraulic cylinder 15 constitute. The control cabinet 2 and the hydraulic station 4 are installed on the base of the body 1, the operation panel 3 is placed on the top of the control cabinet 2, the driving motor 5 is installed on the body 1 and connected to one end of the polyurethane rubber roller 8, and the unloading device 6 is connected to the upper part of the body 1 through screws Connection, the side roller device 7 is connected with the body 1, the polyurethane rubber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com