heat exchanger

A technology of heat exchangers and fluids, applied in heat exchange equipment, heat exchanger shells, indirect heat exchangers, etc., can solve the problem of inability to completely prevent air accumulation, instability of bubble generation parts, and failure of cooling water and external air Efficient heat exchange and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] An embodiment of the present invention will be described below with reference to the drawings.

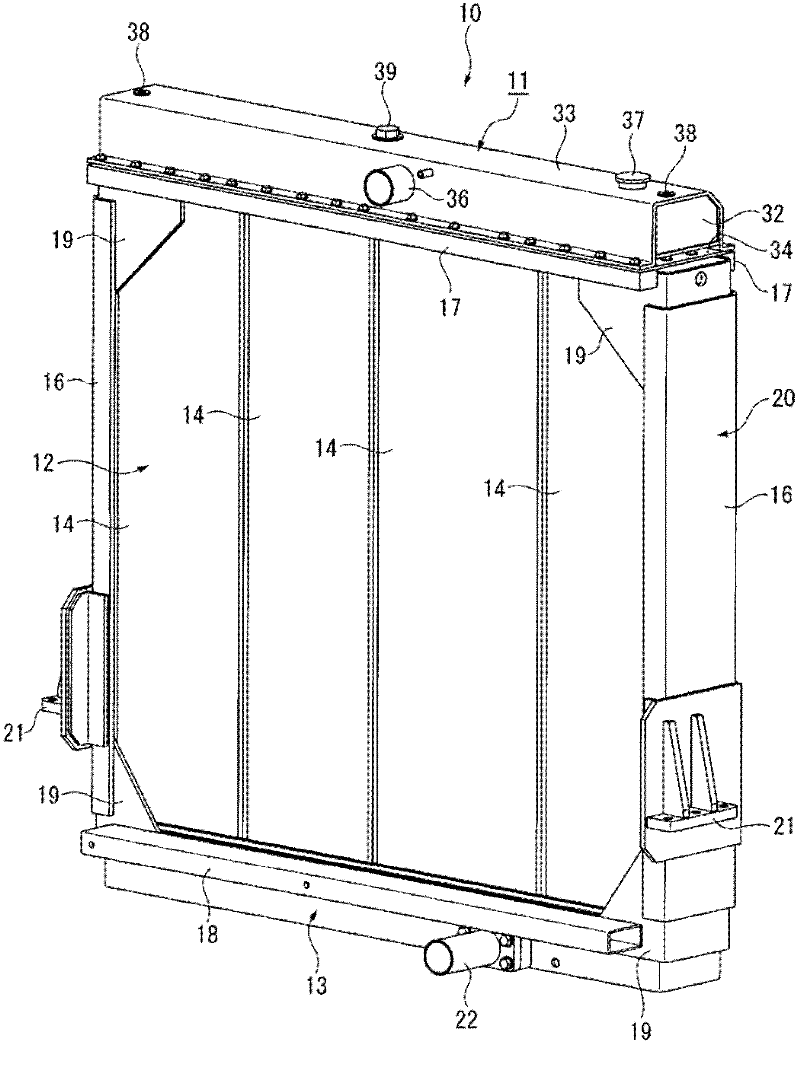

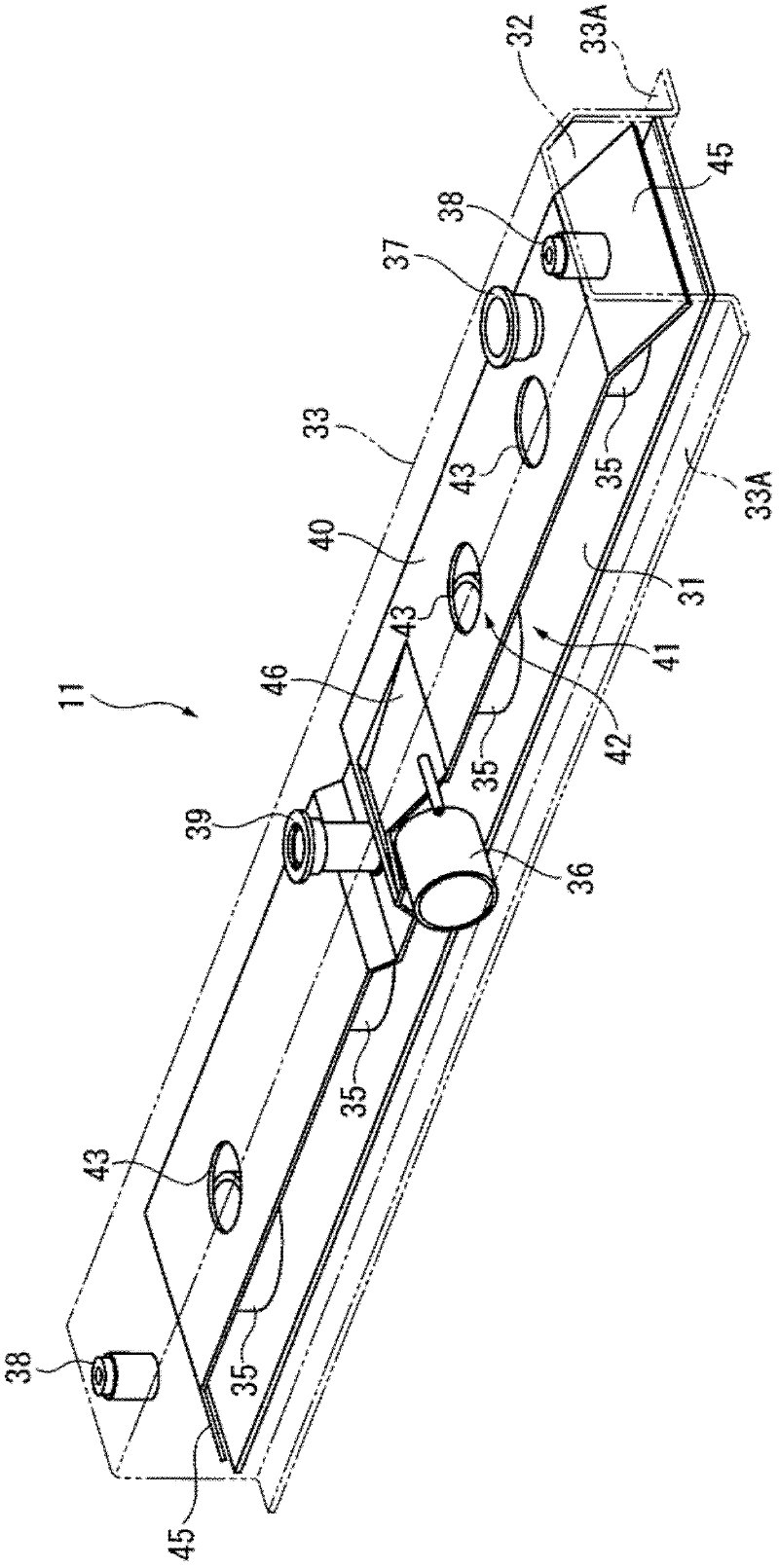

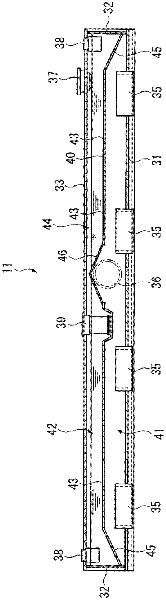

[0023] figure 1 It is a perspective view showing the whole radiator (heat exchanger) 10 according to this embodiment. The radiator 10 is used to cool the cooling water (fluid to be heat-exchanged) of the engine mounted on a large dump vehicle, etc., and it is configured as a vertical flow structure, with an upper tank 11 into which the cooling water from the engine flows, and through Heat exchange between the cooling water flowing inside the upper case 11 and the outside air The core 12 that cools the cooling water, and the lower case 13 that collects the cooling water flowing out of the core 12 and returns it to the engine side water pump of. The upper case 11 will be described later.

[0024] In the present embodiment, the core 12 is constituted by a plurality of (four in the present embodiment) module cores 14 arranged side by side in the horizontal direction. Since t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com