Method for bending and forming metal pipe by placing steel balls inside

A metal pipe, bending forming technology, applied in the field of metal pipe built-in steel ball bending forming, to achieve the effect of easy sealing and removal, large supporting force, and restraining the collapse of the outer wall of the forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

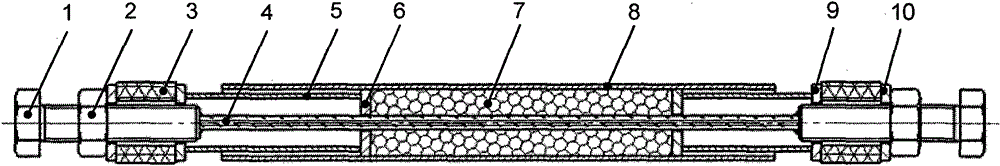

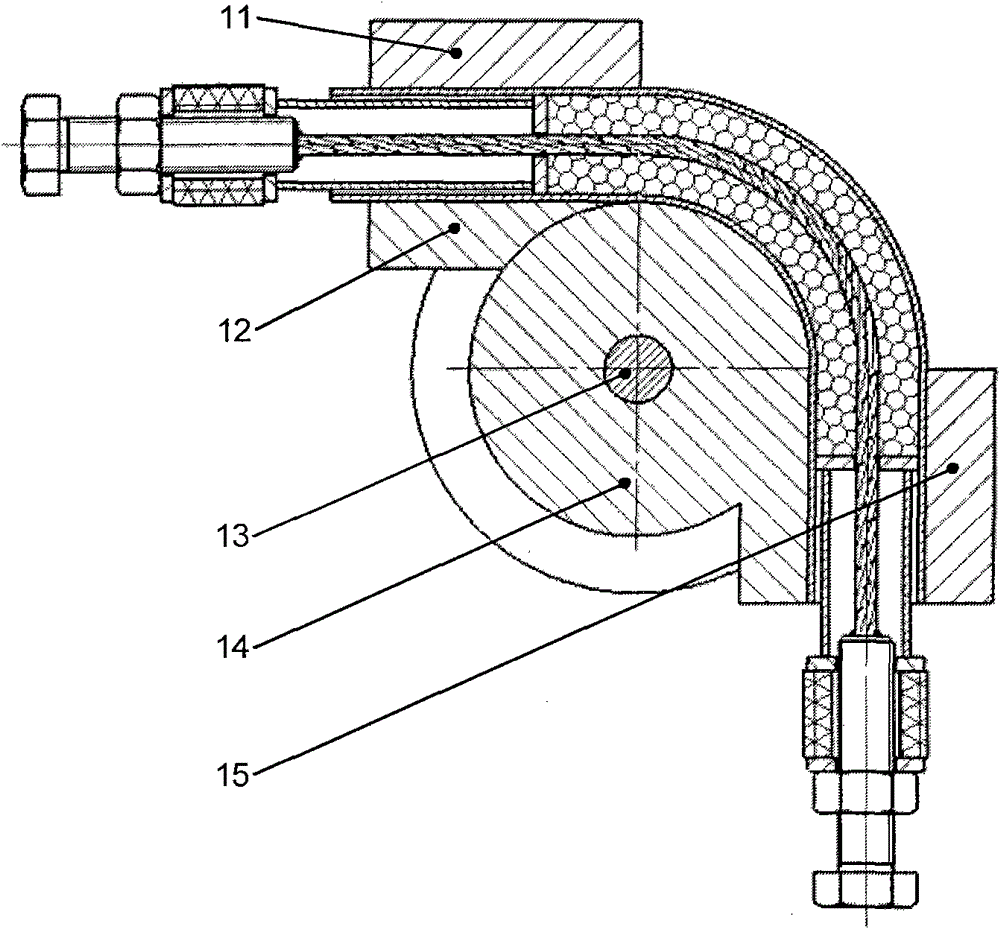

[0017] refer to figure 1 The closed pressure transmission structure at both ends of the metal pipe built-in steel ball consists of tension screw 1, nut 2, rubber spring 3, steel wire rope 4, force transmission tube 5, retaining ring 6, steel ball 7, pipe material 8, inner gasket 9 and outer Composed of gasket 10, the retaining ring 6 is placed in the pipe 8, the steel wire rope 4 penetrates into the pipe 8, and passes through the center hole of the retaining ring 6, one end of the steel wire rope 4 is connected with the tension screw 1, and the tension screw 1 and the nut 2 are movable Connection, the rubber spring 3 is sandwiched between the inner gasket 9 and the outer gasket 10 on the nut 2, one end of the power transmission tube 5 is firmly connected with the inner gasket 9, and the other end is closely connected to the top of the retaining ring 6, and the end of the retaining ring 6 There are built-in steel balls 7 between them, and the advance and retreat of the tension ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com