Spring cable

A spring cable, cable core technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of loss of spring steel wire, increased processing costs, incompatibility, etc., to reduce the concentration of bending stress, low production costs, and avoid localization. damaged effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

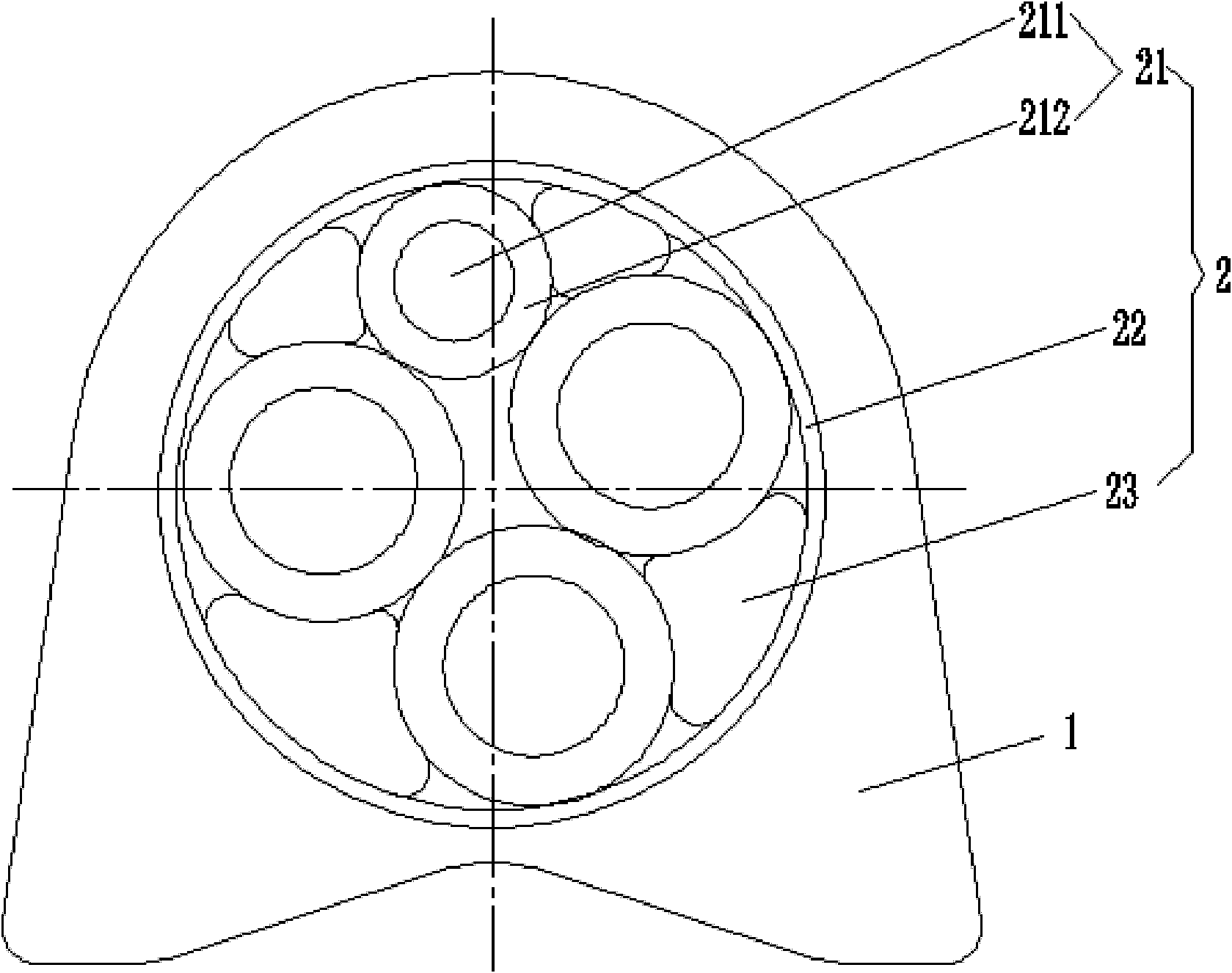

[0031] See figure 1 , the spring cable of this embodiment includes a cable core 2 and a sheath 1 extruded on the outer surface of the cable core 2 .

[0032] The cross-section of the sheath 1 is dovetail-shaped, bounded by the axial plane of the spring cable, the thickness of the lower half is greater than that of the upper half, and the sheath 1 is made of soft PVC material.

[0033] The cable core 2 includes four insulated wire cores 21 , isolation tapes 22 and elastomer filling strips 23 filling the gaps between the insulated wire cores 21 and the isolation tapes 22 . Each insulated wire core 21 includes a conductor 211 and an insulating layer 212 covering the conductor 211; the conductor is a type 5 conductor material, and the insulating layer 212 is an elastomer, which can be selected from natural rubber, ethylene propylene rubber, neoprene and other materials . Four insulated wire cores 21 are twisted into a cable, and the isolation tape 22 is tightly wrapped on the ou...

Embodiment 2

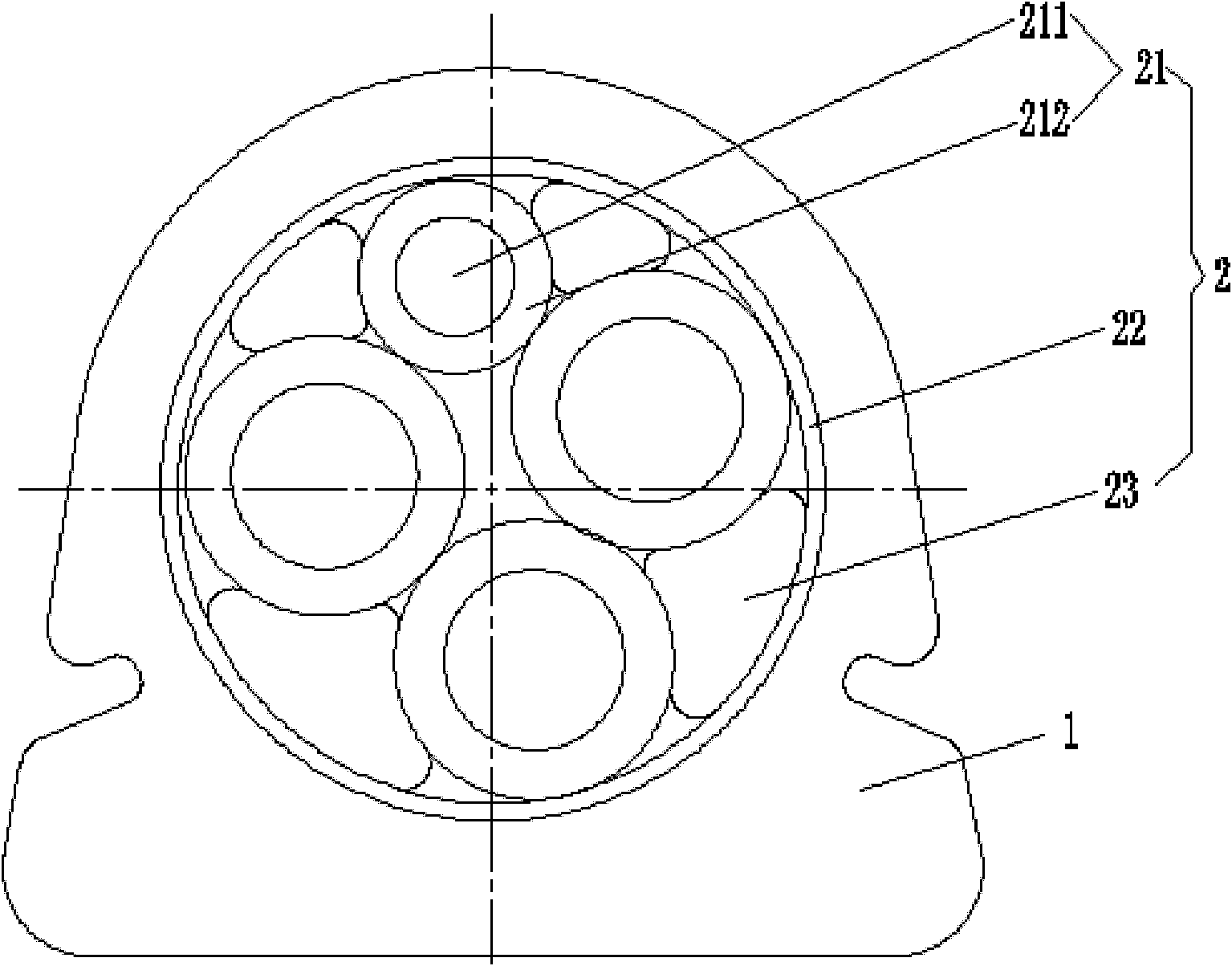

[0036] See figure 2 , the spring cable of this embodiment is basically the same as that of Embodiment 1, the difference is that the cross-section of the sheath 1 is semicircular, bounded by the axial plane of the spring cable, the end face of the lower half is a plane, and in the lower half Grooves are also arranged on the top, and the grooves can assist in absorbing the effect of bending stress and torsional stress generated when the cable is bent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com