Composite conical section forming die pressurized by using soft die

A composite material and molding die technology, used in applications, household components, household appliances, etc., can solve the problems of pressure rise, inability to accurately control pressure, hinder the free expansion of rubber, etc., to improve the degree of compaction and avoid the overall pressure. The effect of uniform and uniform pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

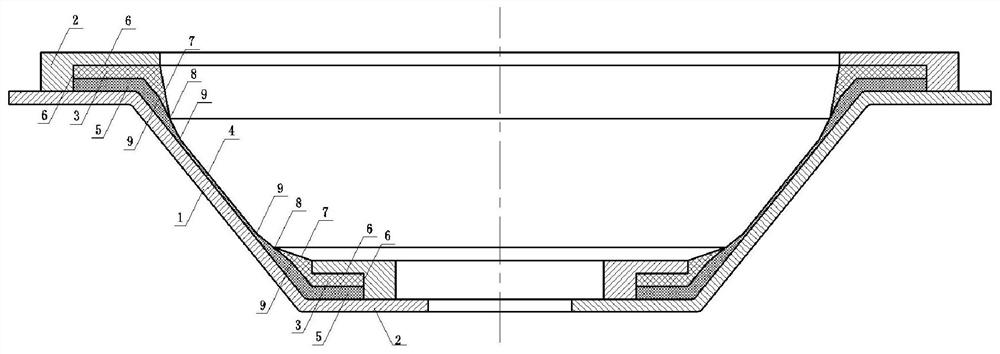

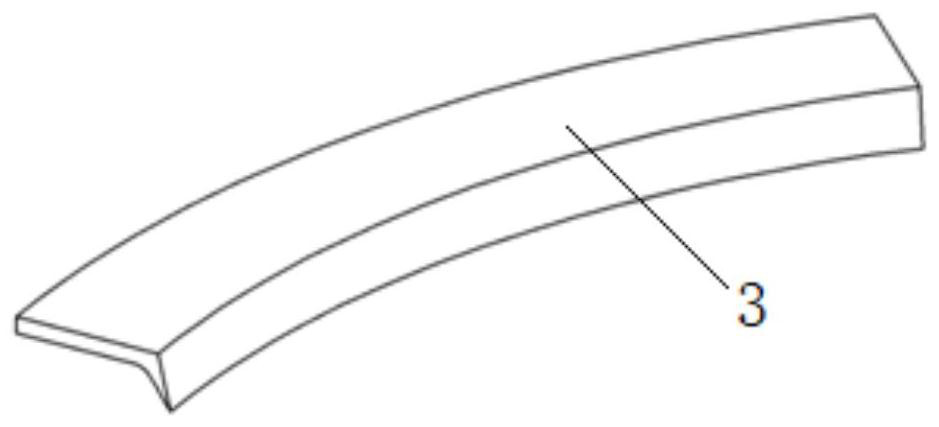

[0034] This embodiment relates to a kind of composite material cone segment molding die that uses soft mold pressurization, such as figure 1 As shown, it includes mold main body 1, rigid outer mold 2 and rubber soft mold 3;

[0035] The mold body 1 is used to support the product 4 to be laid up and cured with prepreg.

[0036] The rigid outer mold 2 is arranged on the end of the mold body 1 and the soft rubber mold 3 to limit the flange end of the product 4 and limit the expansion of the soft rubber mold 3 so that all the expansion is released to the inner surface 7 . The mold of this embodiment is provided with a rigid outer mold 2 limit on the outer surface 6 of the soft rubber mold 3; the inner surface 7 of the soft rubber mold 3 has no rigid outer mold 2 limit, which is used as a pressure relief surface in the curing process to make the soft rubber mold 3 expand. The pressure is consistent with the pressure in the autoclave.

[0037] The soft rubber mold 3 is set on the ...

Embodiment 2

[0049] This embodiment relates to a kind of composite material cone segment molding die that uses soft mold pressurization, such as Figure 5 As shown, it includes mold main body 1, rigid outer mold 2 and rubber soft mold 3;

[0050] The mold body 1 is used to support the product 4 to be laid up and cured with prepreg.

[0051] The rigid outer mold 2 is set on the end of the mold main body 1 and the soft rubber mold 3 to limit the flange end of the product 4 and limit the expansion of the soft rubber mold 3, so that the expansion can release pressure to the inner surface 7 and the outer side Face 10 is released.

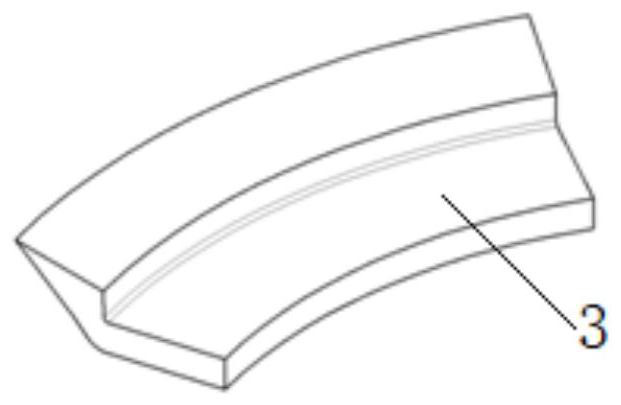

[0052] And, different from Example 1, in order to better avoid fiber buckling, the outer side pressure relief surface 10 without steel mold constraints is arranged at intervals on the lateral outer side 6 of the soft rubber mold 3 of this embodiment (the outer side pressure relief surface 10 is not the whole circle); as in Image 6 shown. This setting enables the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com