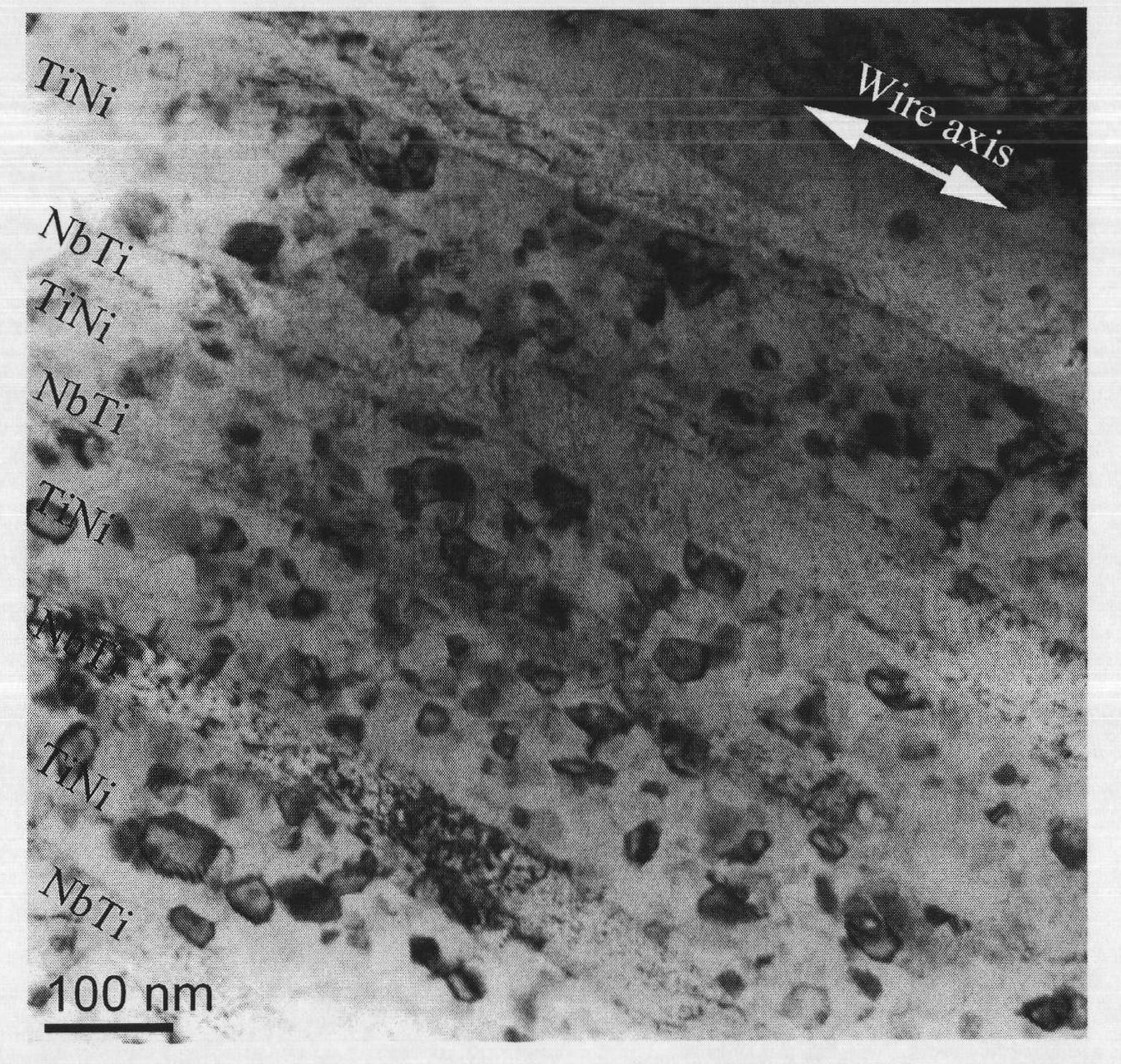

NbTi/TiNi memory alloy composite material and preparation method thereof

A technology of composite materials and memory alloys, which is applied in the field of memory alloy composite materials with in-situ self-generated ultrafine eutectic structure in the cast state and its preparation field, which can solve the limitations of the shape memory effect of TiNi alloys, the inability of superelasticity to be fully coupled with the matrix Memory alloy composite material functional properties and other issues, to achieve the effect of good interface bonding and high interface bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The preparation method of NbTi / TiNi memory alloy composite material provided by the invention can comprise the following specific steps:

[0046] (1) Select niobium with a purity of 99.0wt.%-99.9wt.% according to the composition ratio of the composite material, titanium with a purity of 99.0wt.%-99.9wt.%, titanium with a purity of 99.0wt.%-99.9wt.% nickel;

[0047] (2) Putting the above-mentioned composite material components into a smelting furnace, smelting to obtain the NbTi / TiNi memory alloy composite material, and casting it into an ingot;

[0048] (3) In the vacuum furnace (the ultimate vacuum degree is 6.7×10 -4 Pa), the ingot was subjected to homogenization annealing treatment for 10 hours at 950° C.;

[0049] (4) Hot forging the annealed ingot at 850°C into rod-shaped material (rod-shaped ingot) or cake-shaped material (cake-shaped ingot);

[0050] (5) Plastic processing is repeated on the rod-shaped material or cake-shaped material obtained by hot forging u...

Embodiment 1

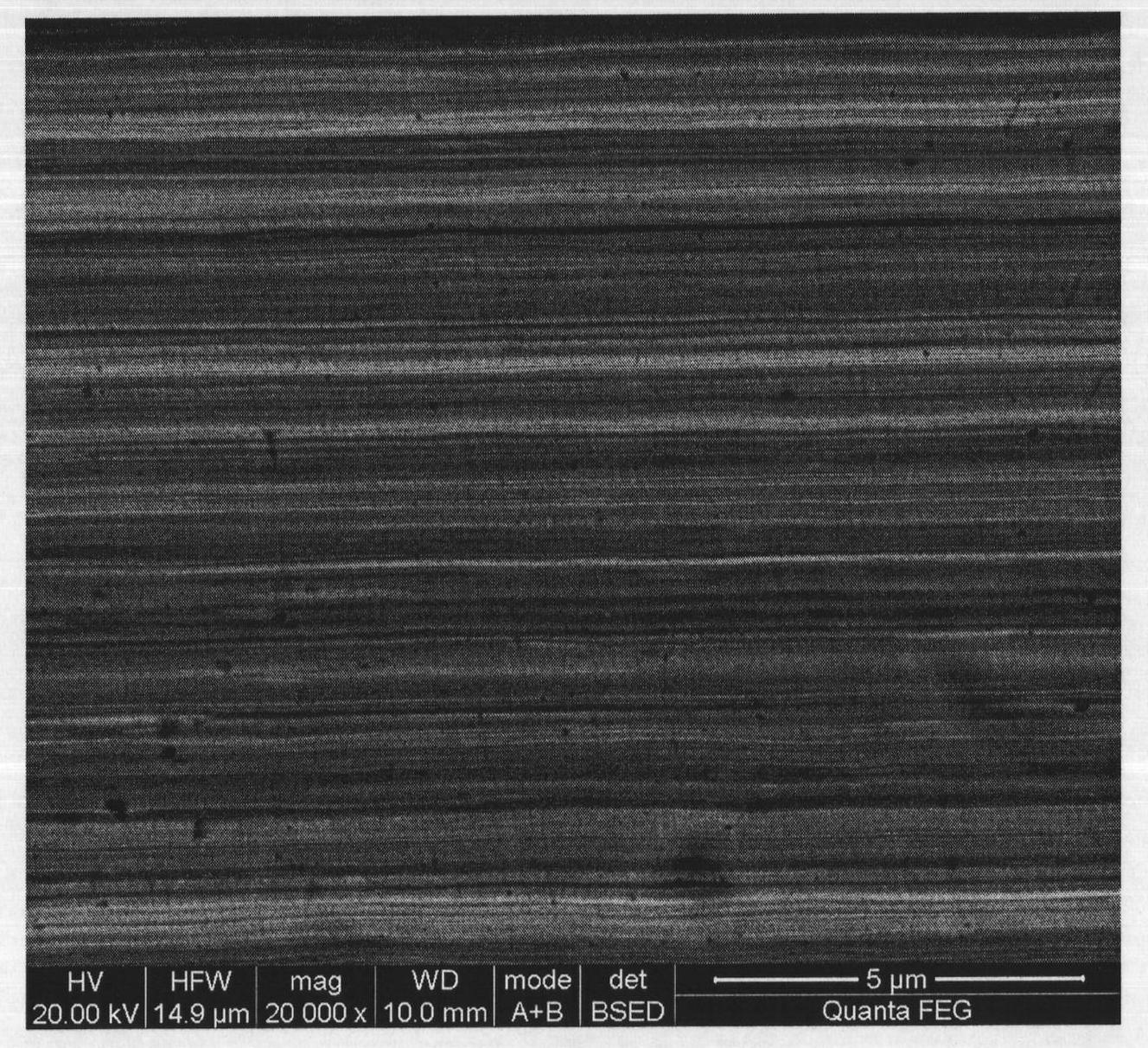

[0051] Example 1: Nb 20 Ti 42 Ni 38 memory alloy composite

[0052] (1) by Nb content 20at.%, the proportioning of Ti and Ni atomic ratio 21: 19 selects the niobium that purity is 99.9wt.%, the titanium that purity is 99.9wt.%, the nickel that purity is 99.9wt.%, wherein , the sum of the atomic percentages of Nb, Ti and Ni is 100%;

[0053] (2) Put the above-mentioned alloy components into a vacuum melting furnace, and melt them into ingots under the protection of argon at -0.05MPa;

[0054] (3) In the vacuum furnace, the ingot is subjected to homogenization annealing treatment for 10 hours at 950° C.;

[0055] (4) Hot forging the annealed ingot into a rod-shaped material (rod-shaped ingot) at 850°C;

[0056] (5) At 600°C, the rod-shaped material obtained by hot forging is hot-drawn to obtain a wire with a diameter of 1mm;

[0057] (6) annealing the wire material obtained in step (5) at 750° C. for 3 minutes;

[0058] (7) cold drawing the wire material obtained in step ...

Embodiment 2

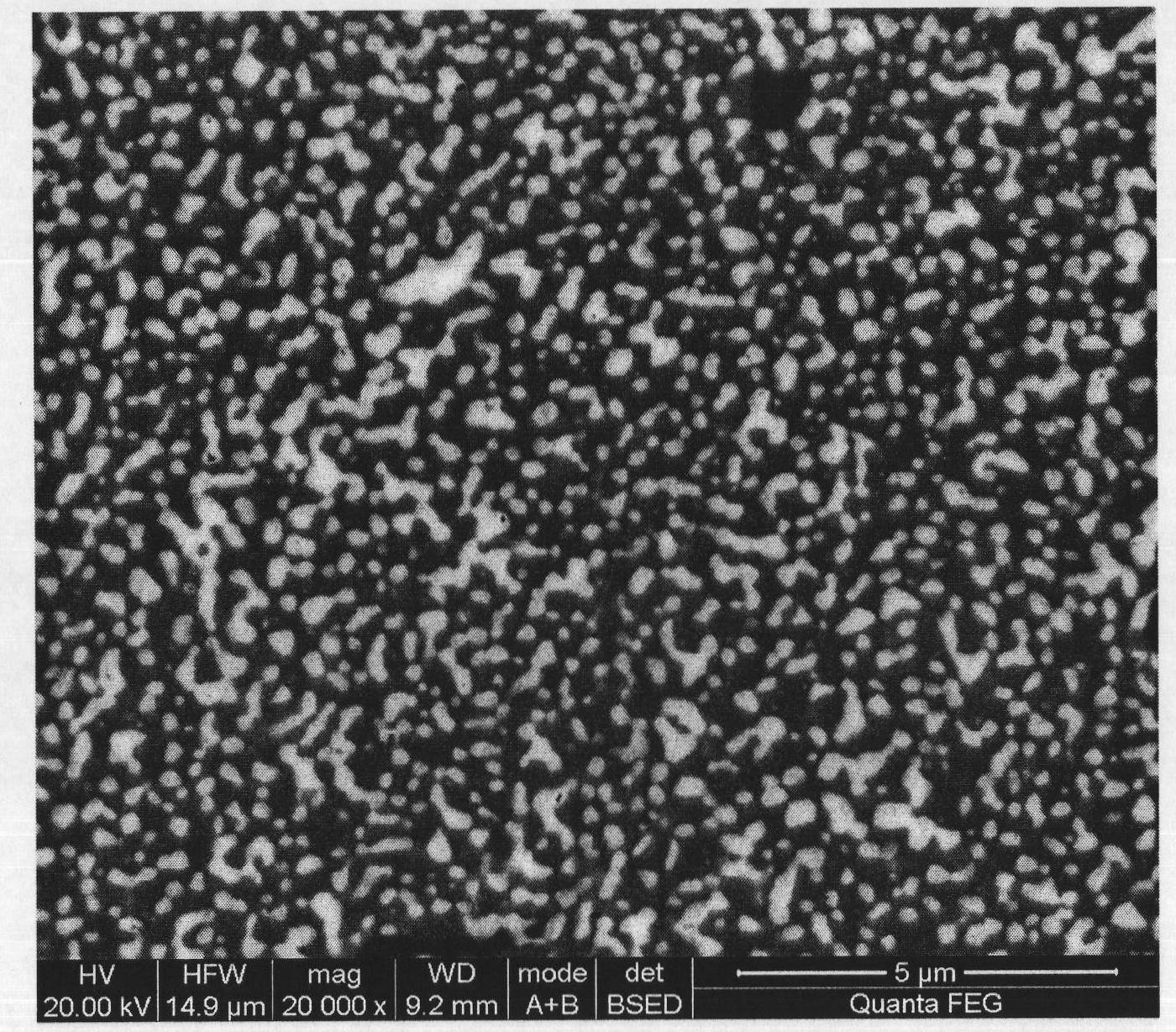

[0067] Example 2: Nb 20 Ti 37 Ni 43 memory alloy composite

[0068] (1) by Nb content 20at.%, the ratio of Ti and Ni atomic ratio 37:43 selects the niobium that purity is 99.9wt.%, the titanium that purity is 99.9wt.%, the nickel that purity is 99.9wt.%, wherein , the sum of the atomic percentages of Nb, Ti and Ni is 100%;

[0069] (2) Put the above-mentioned alloy components into a smelting furnace, melt and cast them into button-shaped ingots under the protection of -0.5MPa argon;

[0070] (3) In the vacuum furnace, the ingot is subjected to homogenization annealing treatment for 10 hours at 950° C.;

[0071] (4) At 850°C, hot forge the annealed button-shaped ingot radially into a cake-shaped material (cake-shaped ingot) with a thickness of 10 mm;

[0072] (5) cold rolling the cake-shaped material obtained by hot forging, the cold rolling deformation is 50%-60%;

[0073] (6) annealing the cold-rolled material at 800° C. for 20 minutes;

[0074] (7) Step (5) and step (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com