Magnetorheological fluid soft die forming method and device for deep-cavity thin-wall component

A magnetorheological fluid and thin-walled component technology, applied in the field of sheet metal forming, can solve problems such as difficulty and complex magnetic field regulation procedures in different regions, achieve good deformation, good application prospects, and solve the effects of complex regulation procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

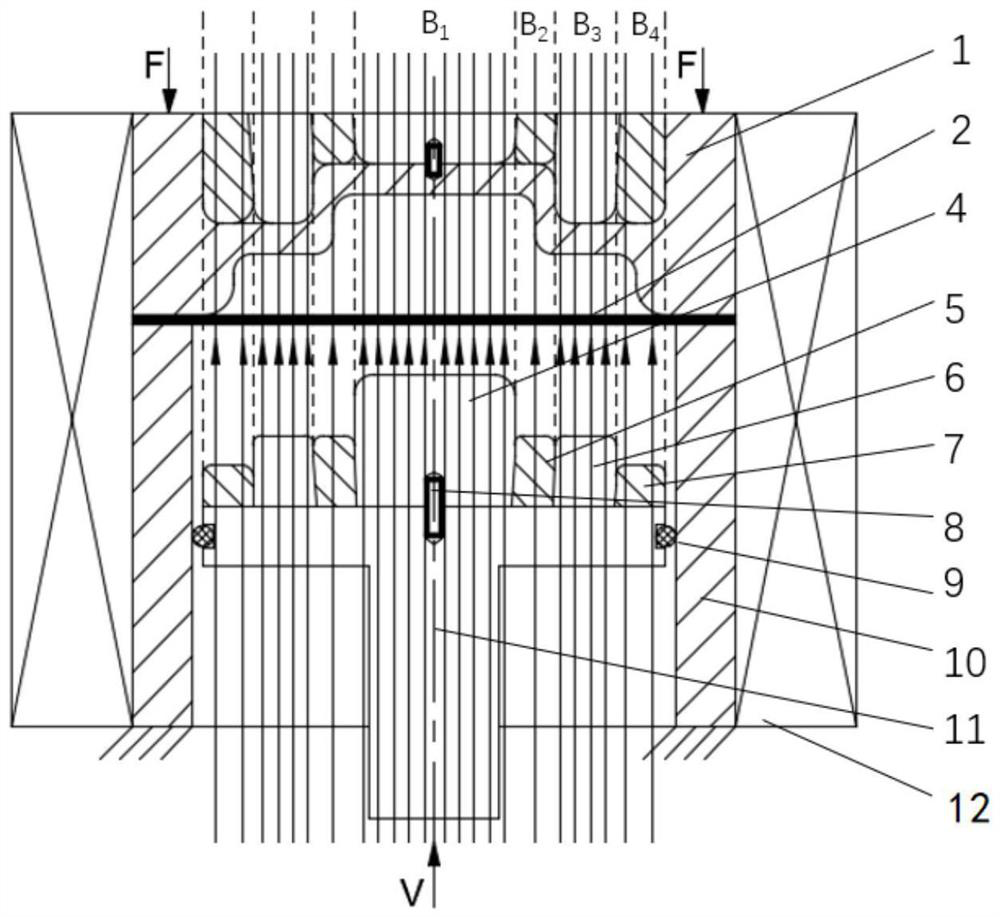

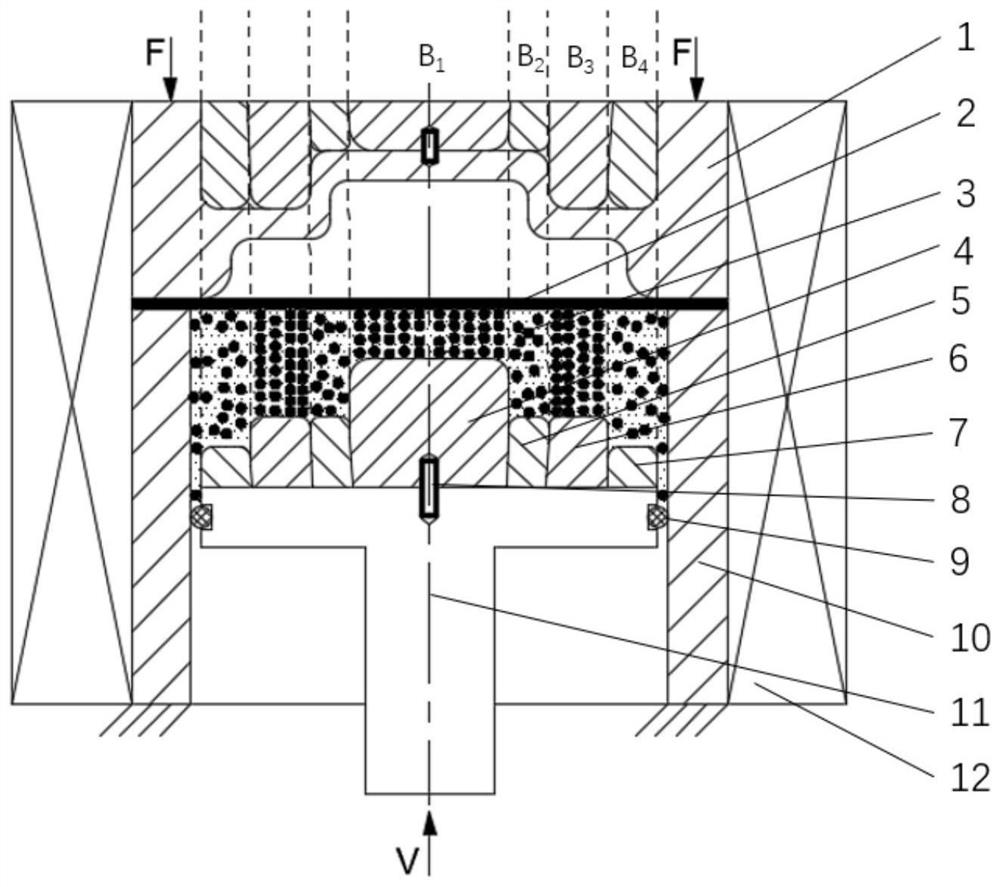

[0050] like figure 2 , 3 And 4, in this embodiment, it is necessary to process a step-shaped deep cavity thin-walled complex part, which has a plurality of rounded corners with small radius, and the rounded corners are prone to thinning of wall thickness due to large deformation and large force. Even cracking is a difficult-to-form structure in the forming process of the part. According to the geometry of the part, a smaller magnetic field strength is used in the fillet area, so that the material in this part is less stressed, and the plate / liquid friction coefficient is small to facilitate the flow of the material; The forming limit of the large plate will increase first and then decrease. Select a larger magnetic field strength in the parallel area, and control the magnetic field strength to increase the forming limit. As mentioned above, the use of iron core components in the parallel area increases the magnetic field strength in the parallel area; the use of non-magneti...

Embodiment 2

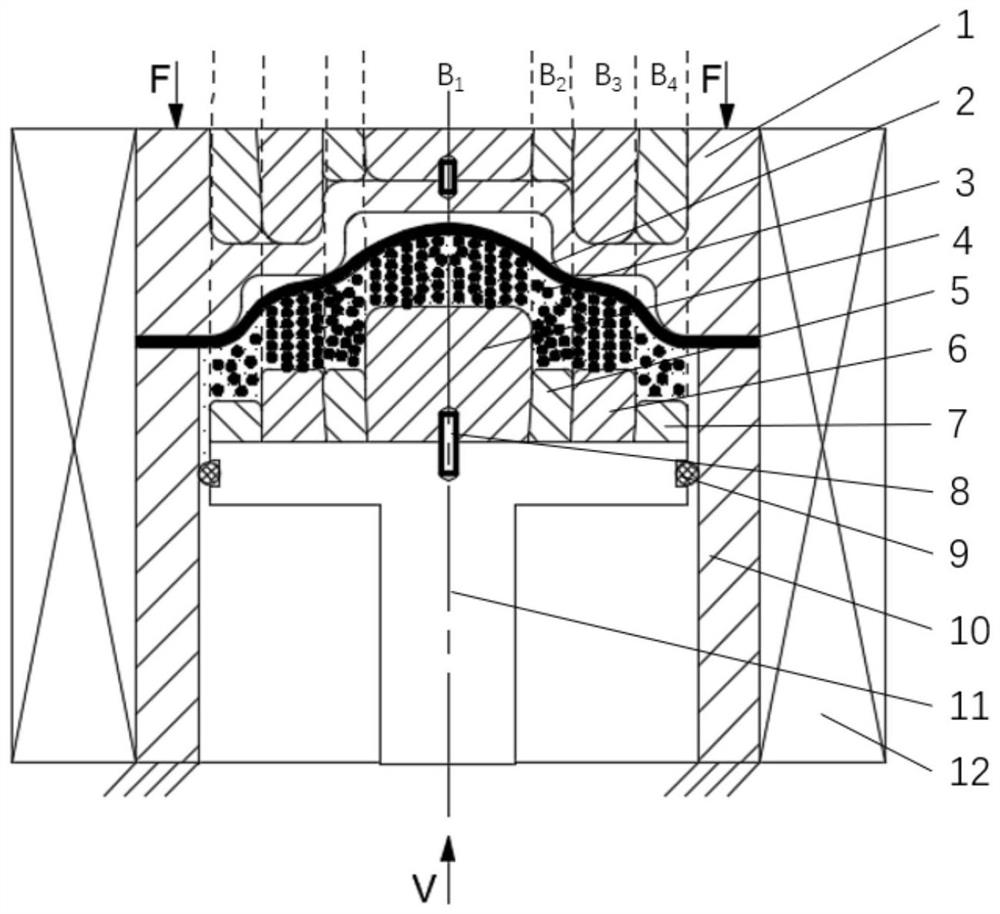

[0060] like Figure 5 , 6 And 7, in this embodiment, a hump-shaped deep cavity thin-walled complex part needs to be processed, and the part has two small-radius fillets and one large-radius fillet. According to the geometry of the part, use a smaller magnetic field strength in the fillet area, so that the material in this part is less stressed, and the plate / liquid friction coefficient is small to facilitate the flow of the material; choose a larger magnetic field strength in the hump area to control the magnetic field strength to increase the forming limit. As mentioned above, iron core components are used in the hump area to enhance the magnetic field strength in the parallel area; non-magnetic steel is used in the rounded area to weaken the magnetic field strength in the rounded area.

[0061] The specific processing steps are:

[0062] Step 1, according to the shape of the parts, design the positions and shapes of the first iron core piece 4, the first non-magnetic stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com