Automotive back seat restraint system test bed

A restraint system and test bench technology, which is applied in vehicle testing, machine/structural component testing, measuring devices, etc., can solve the problems of extended development cycle, inability to test and verify the restraint system of the whole vehicle, and increased development costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

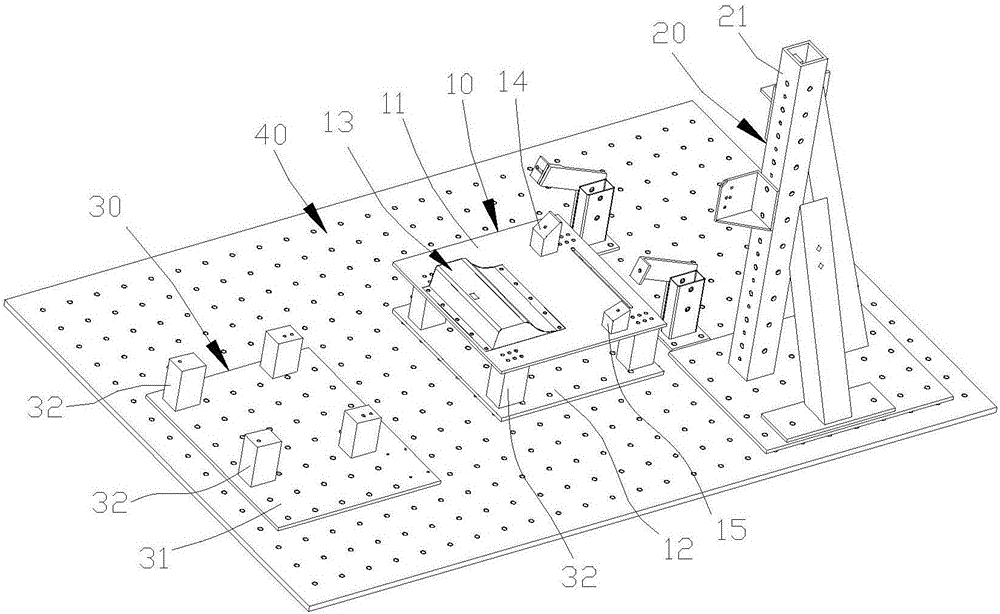

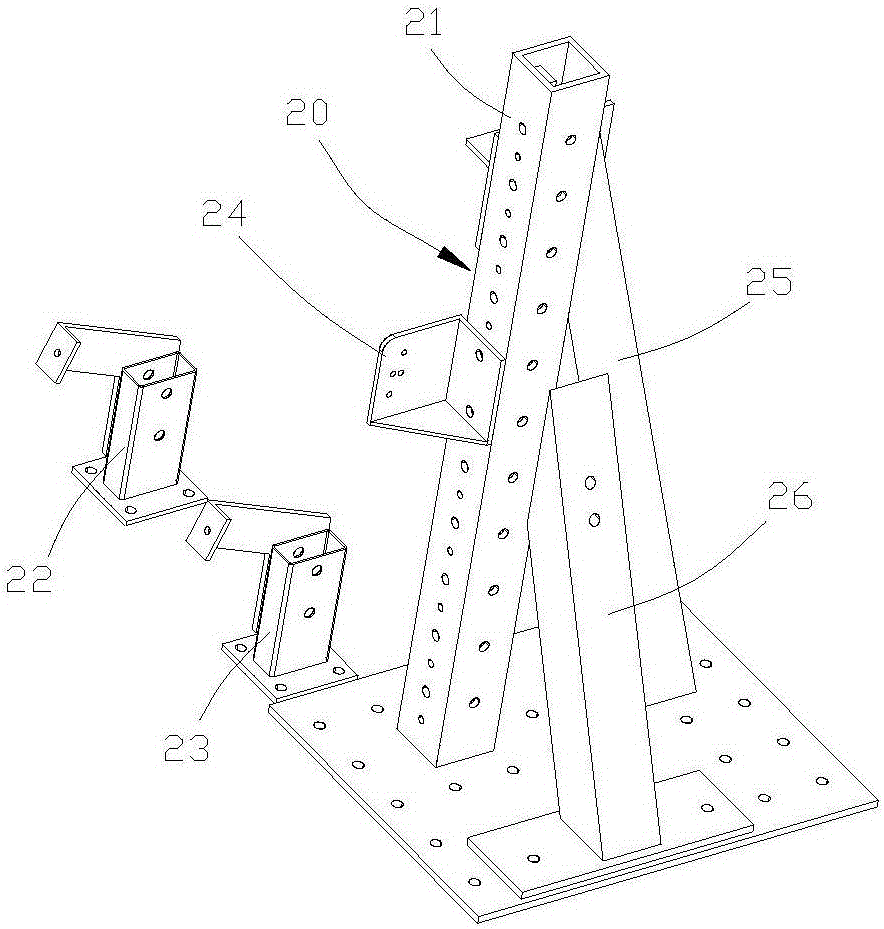

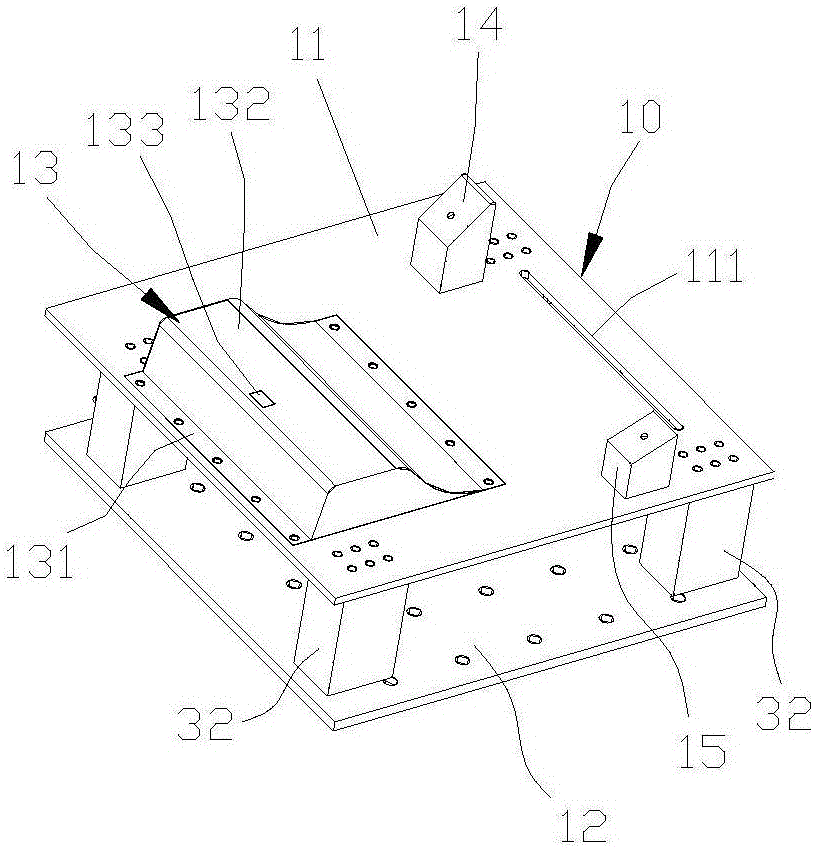

[0010] Combine below Figure 1 to Figure 3 , the present invention is described in further detail.

[0011] A test bench for the rear restraint system of an automobile, comprising a slide table 40 and a front seat fixing unit 30 and a rear seat fixing unit 10 arranged on the slide table 40, a bracket assembly is arranged on the side of the rear seat fixing unit 10 20. The rear seat fixing unit 10 includes an upper base plate 11 and a lower base plate 12 fixed to the upper base plate 11, and the upper base plate 11 is fixed with an anti-submergence plate 13, a lock mounting frame 14 and a safety belt fixing block 15. In the actual operation process, the lower base plate 12 in the rear seat fixing unit 10 is fixed on the slide table 40, then the upper base plate 11 is fixed with the lower base plate 12 through the fixing block 31, and then the anti-submarine plate 13 and the lock catch are respectively installed Frame 14 and seat belt fixing block 15 are fixed on the plate sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com