Interior wall screeding method

A technology for punching bars and interior walls, which is applied in the direction of architecture and building construction, and can solve problems such as difficulty in meeting the requirements for the depth of bays, inability to accurately control the thickness of punching bars, and excessive plastering of the base of the wall, so as to reduce the risk of rectification , It is beneficial to measure the distance and control the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

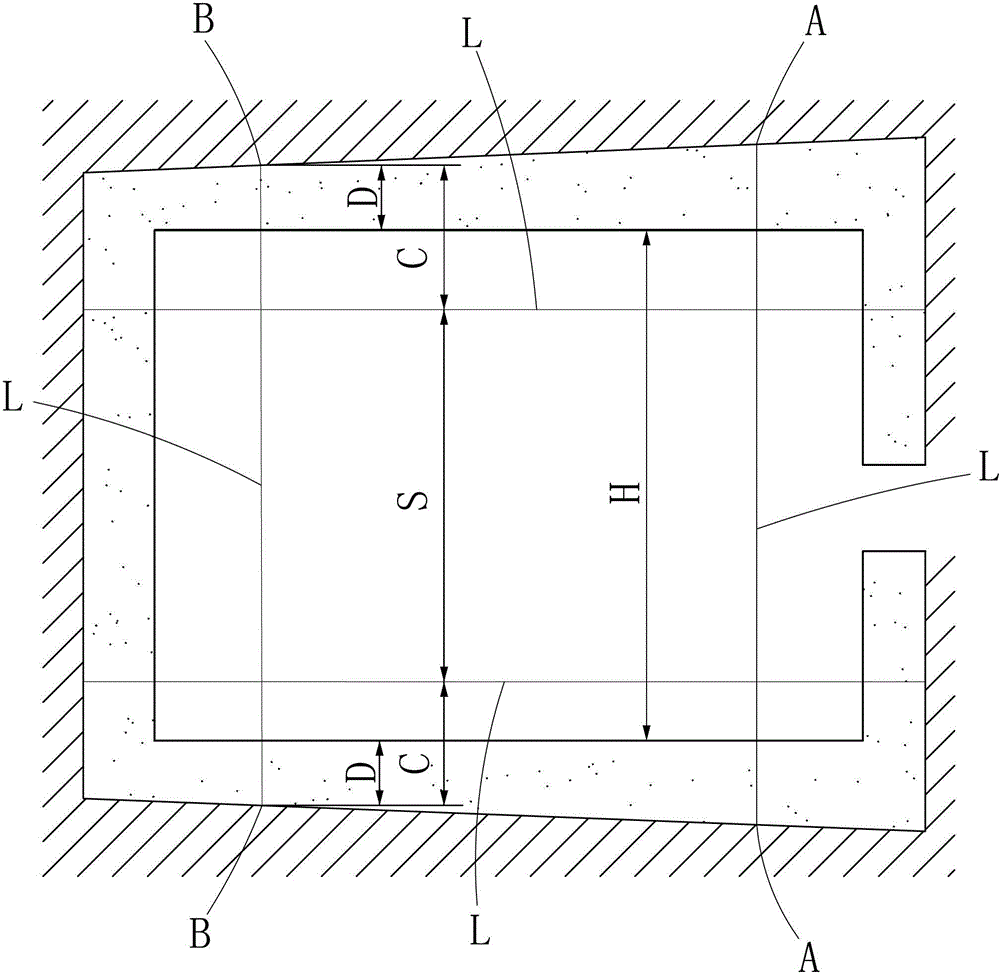

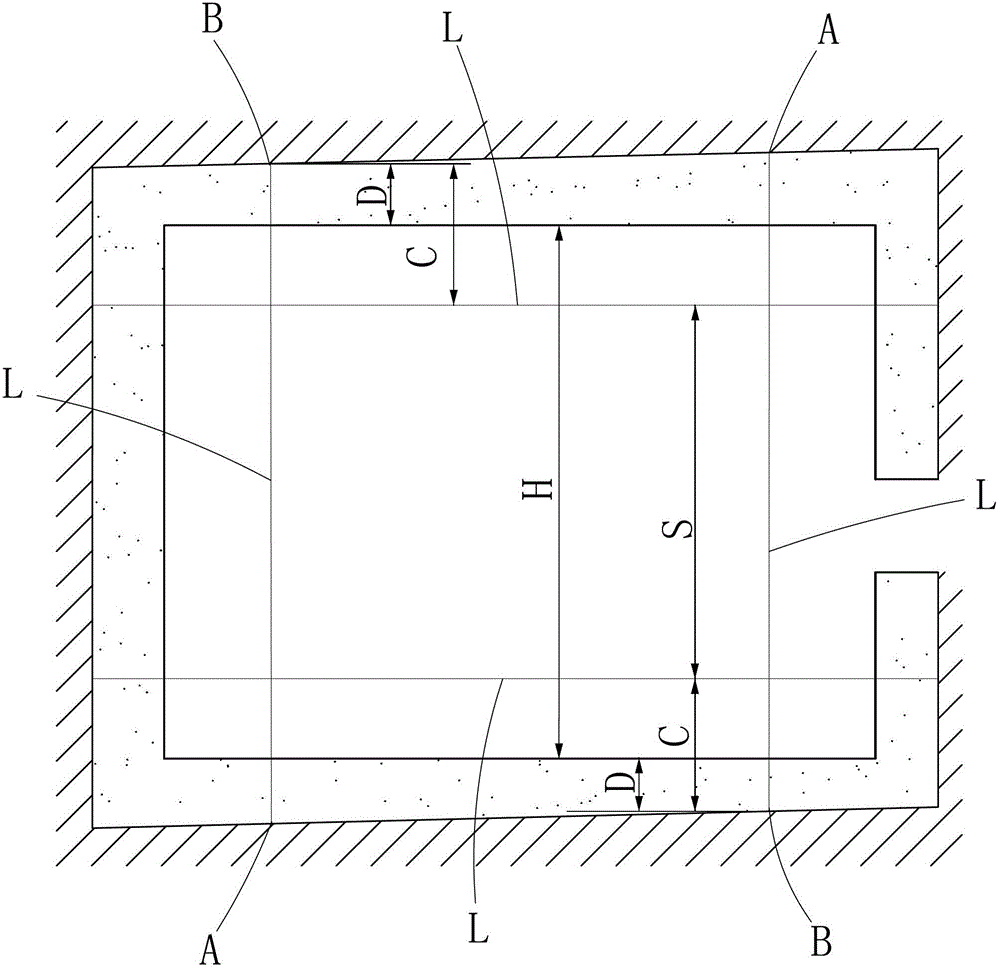

[0024] For the convenience of description, only the figure 1 and figure 2 Among them, the control of punching bars on the upper and lower sides of the relative wall base will be described, and the other two wall bases can be controlled according to the same steps.

[0025] A method for punching ribs in an interior wall of the present invention comprises the following steps: a. processing the base layer of the wall body; b. adjusting the squareness of the laser level; c. measuring the distance between the horizontal ends of the base layer of the wall body and the control line; d. calculating the proximal end of the base layer of the wall body plastering thickness; e, marking standard points; f, punching ribs.

[0026] a. Treatment of the base of the wall, that is, cleaning the dirt on the surface of the base of the wall, knocking out the discarded wooden formwork, steel bars, concrete blocks, etc. object interference.

[0027] b. Adjust the squareness of the laser level, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com