Method of rending plasters on wall with high precision

A high-precision, cake-sticking technology, applied in construction, building structure, building material processing, etc., can solve the problems of complex procedures, low efficiency, high requirements for construction personnel, etc., to reduce the deviation of ash cake, improve efficiency, yin and yang The effect of improved corner squareness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

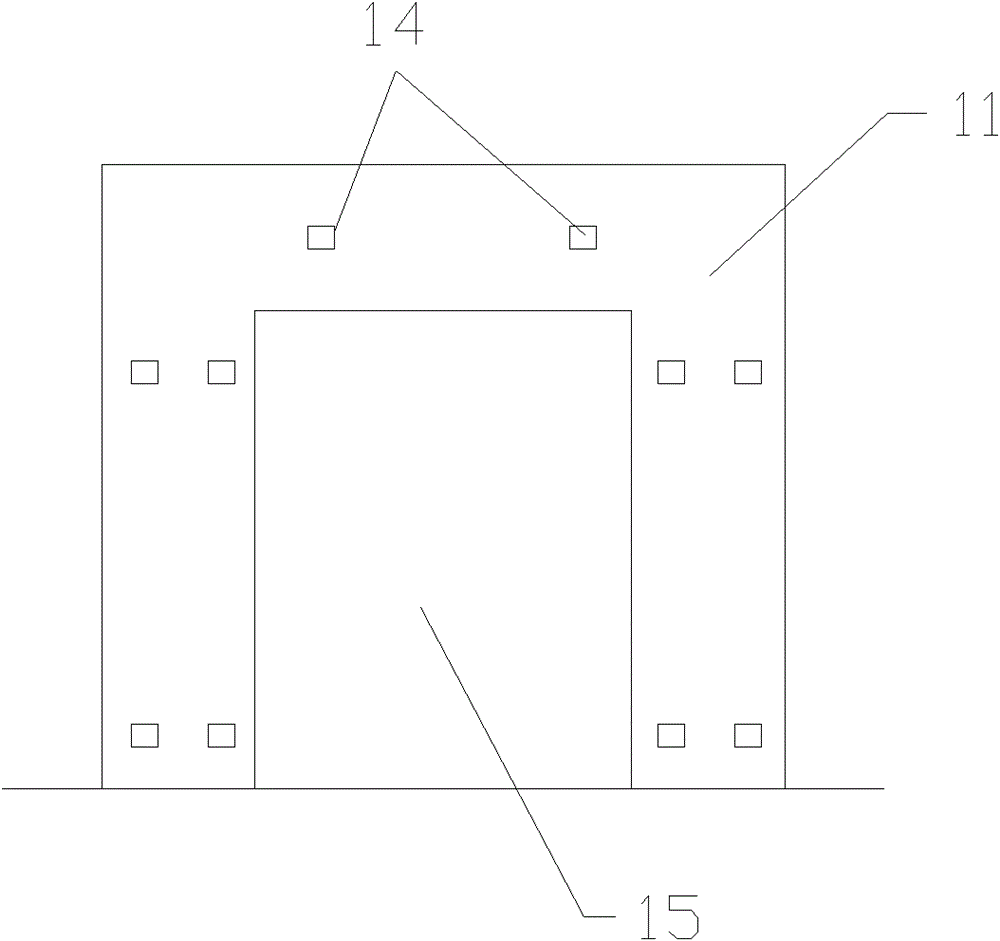

[0027] The invention uses a laser sweeper to control plastering and sticking cakes, which simplifies the sticking complexity of the gray cakes while improving the sticking precision of the gray cakes, and greatly improves the efficiency.

[0028] The high-precision wall pasting cake method of the present invention specifically comprises the following steps:

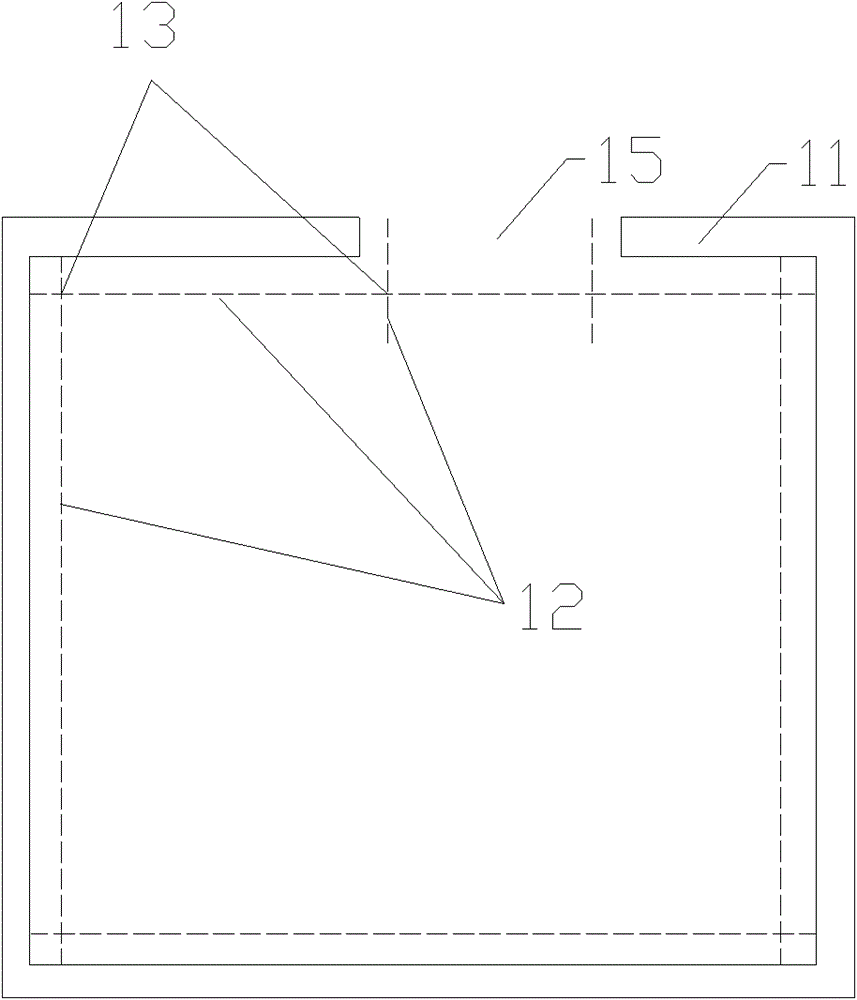

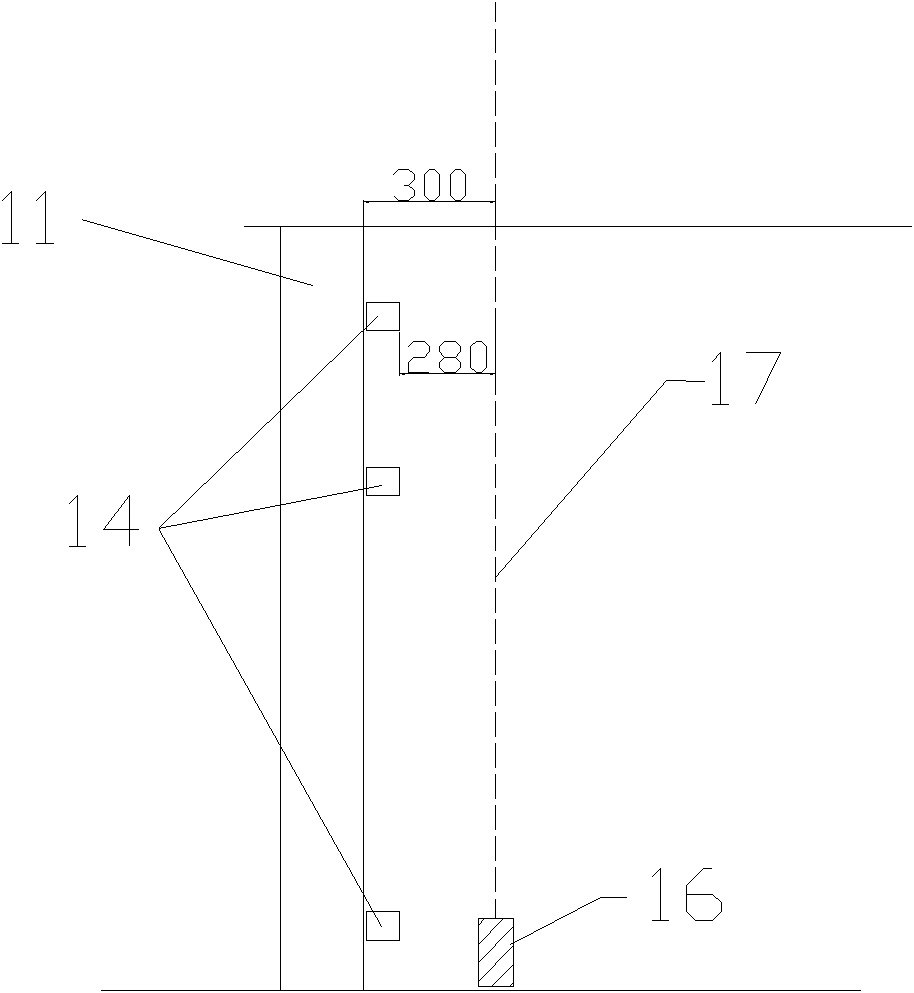

[0029] Step 1, setting the control line 12 on the ground, the control line 12 is parallel to the wall 11 (building interior wall) and the distance from the control line to the wall is the first distance, as figure 1 shown.

[0030] In this step, the control line 12 can be set according to the drawings, so as to ensure that the entire plastering effect is completely consistent with the design. Usually, the above-mentioned first distance is 300 mm, that is, the distance from the control line to the wall is 300 mm.

[0031] Step 2, setting the laser leveling device 16 according to the control line 12 and making the laser l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com