Machining method of special-shaped hollow structure composite part molding mandrel

A composite material and processing method technology, which is applied in the field of autoclave molding of resin-based fiber-reinforced composite material prepreg, can solve the problems of difficult demoulding and high mold cost, and achieve the effects of low cost, simple processing and convenient demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

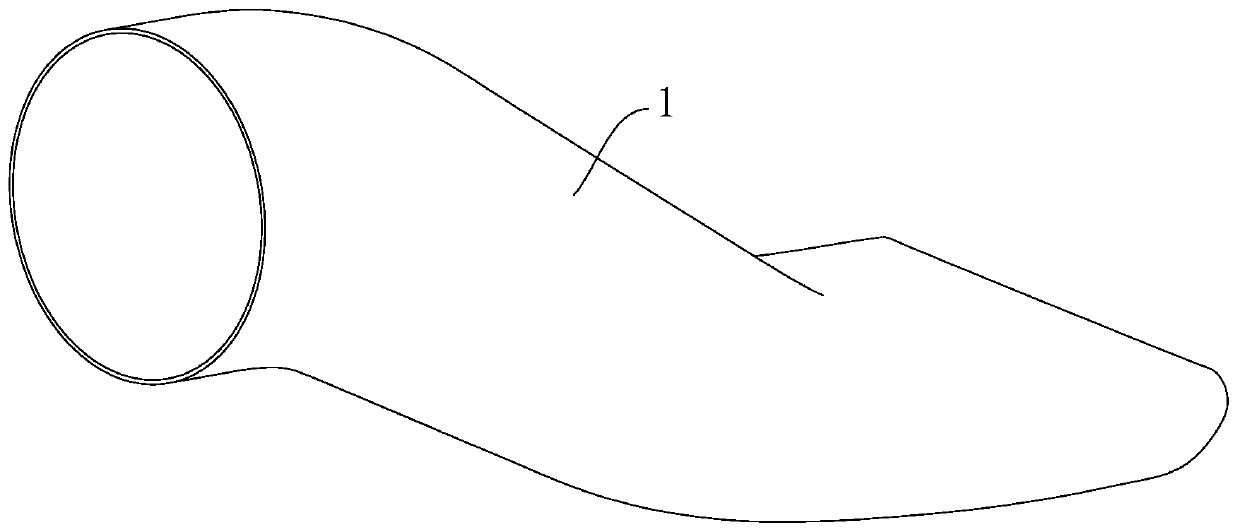

[0041] see Figure 1-Figure 9 . The embodiment of the present invention provides a processing method for forming a core mold 3 of a composite material part 1 with a variable cross-section and special-shaped hollow revolving body structure. see Figure 8 and Figure 9 , this processing method can obtain a kind of molding mandrel 3. This molding mandrel 3 can be used for processing such as figure 1 The variable cross-section special-shaped hollow rotary structure composite material part 1 is shown.

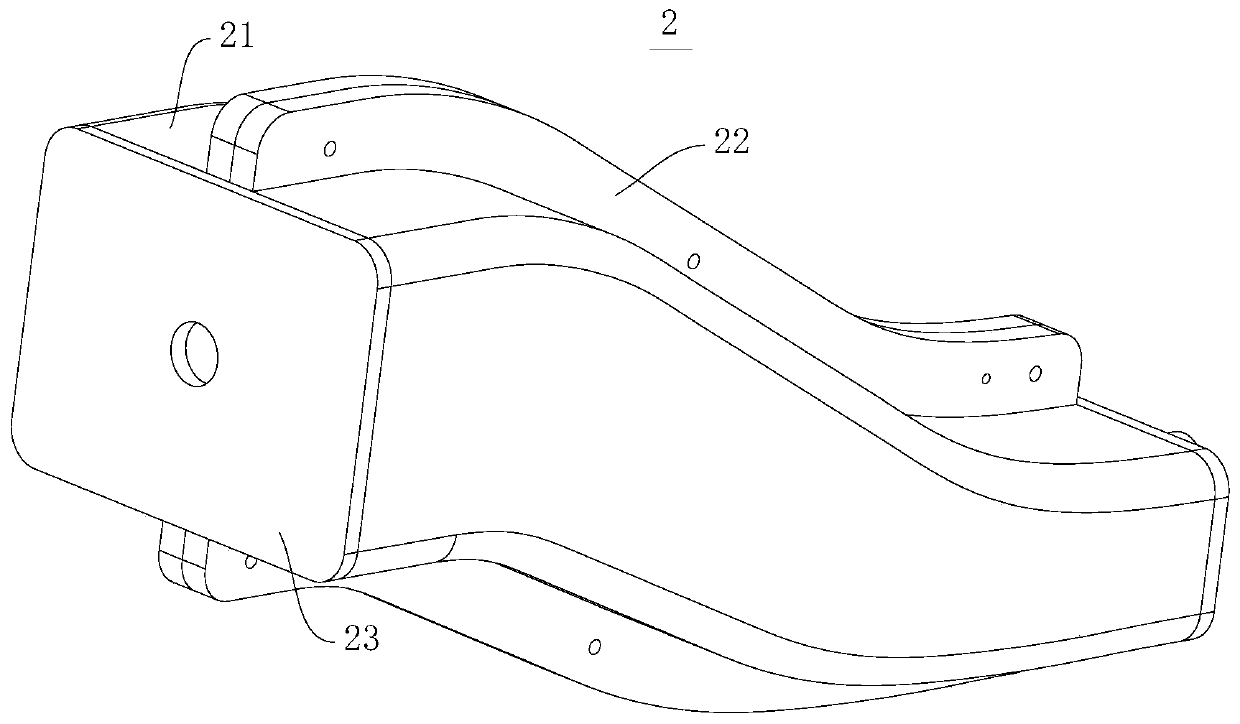

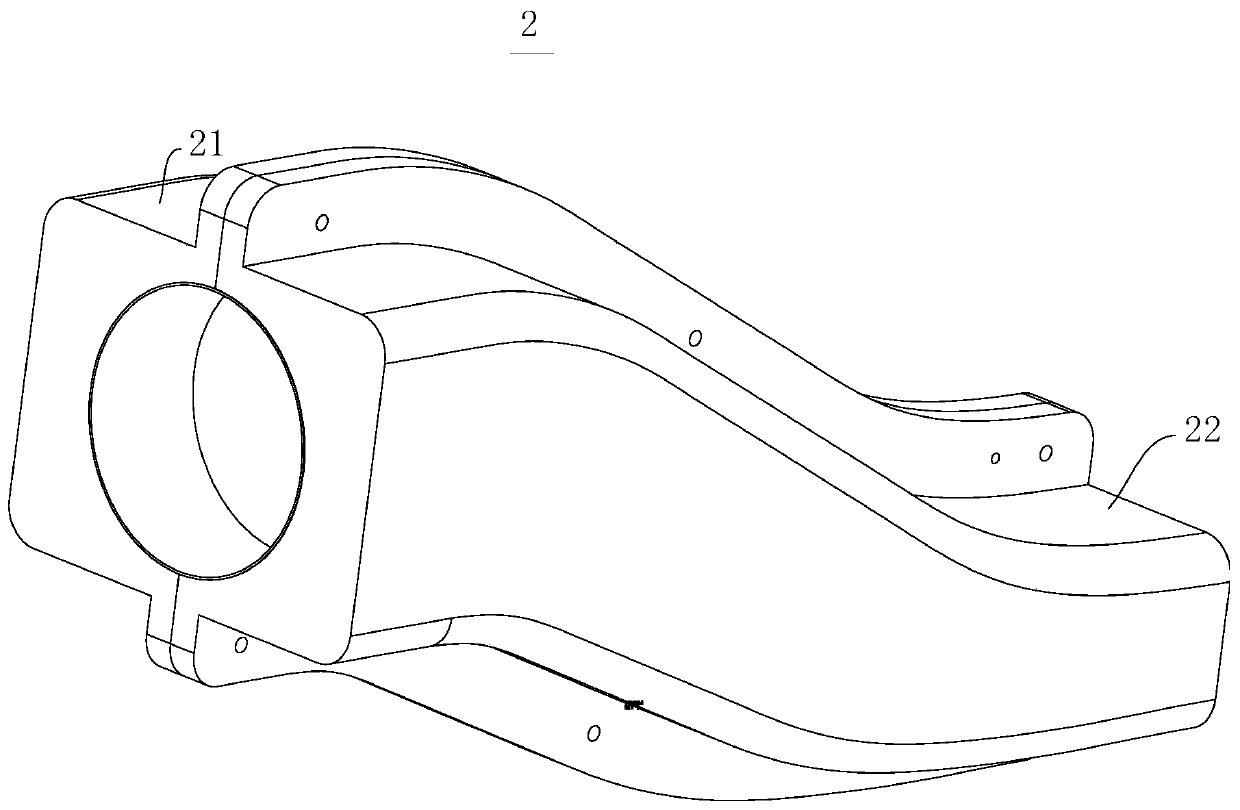

[0042] see figure 2 and image 3 The processing method provided by the embodiment of the present invention adopts a core mold forming mold 2, and the core mold forming mold 2 includes a first mold body 21, a second mold body 22 and a sealing plate 23. The first mold body 21 and the second mold body 22 are detachably connected. When the first mold body 21 and the second mold body 22 are connected, a molding space can be formed, and the shape of the molding space is adapted t...

example ( 1

[0077] see Figure 10-Figure 13 , when the above-mentioned molding mandrel 3 is used for the processing of the composite material part 1 with a variable cross-section special-shaped hollow rotary structure with high requirements on the surface quality and precision of the inner surface:

[0078] A1. fixing the forming mandrel 3 by a support rod 33;

[0079] Wherein, clamping support bar 33, can realize the fixing of forming mandrel 3, thereby make the surface of whole soft mold 31 not be blocked, be convenient to carry out the paving of composite material layer.

[0080] A2. on the surface of the soft mold 31, stick a release cloth with glue;

[0081] If multiple release cloths are required to cover the surface of the soft mold 31, two adjacent release cloths are butted together instead of spliced. That is: the edges of two adjacent release cloths are in contact, but the two release cloths do not overlap in the thickness direction. Through this arrangement, the surface qual...

example ( 2

[0091] see Figure 14-Figure 16 , when the above-mentioned molding mandrel 3 is used for the processing of the composite material part 1 with a variable cross-section special-shaped hollow rotary structure with high requirements on the surface quality and precision of the outer surface:

[0092] B1. fixing the forming mandrel 3 by a support rod 33;

[0093] Wherein, clamping support bar 33, can realize the fixing of forming mandrel 3, thereby make the surface of whole soft mold 31 not be blocked, be convenient to carry out the paving of composite material layer.

[0094] B2. Lay adhesive release cloth on the surface of soft mold 31;

[0095] If multiple release cloths are required to cover the surface of the soft mold 31, two adjacent release cloths are butted together instead of spliced. That is: the edges of two adjacent release cloths are in contact, but the two release cloths do not overlap in the thickness direction. Through this arrangement, the surface quality of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com