Multi-headed isopach deep agitation driller

A deep mixing and equal thickness technology, applied in rotary drilling rigs, drilling equipment, earth-moving drilling, etc., can solve the problems of bit deviation and bifurcation, slow cutting speed and discontinuity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

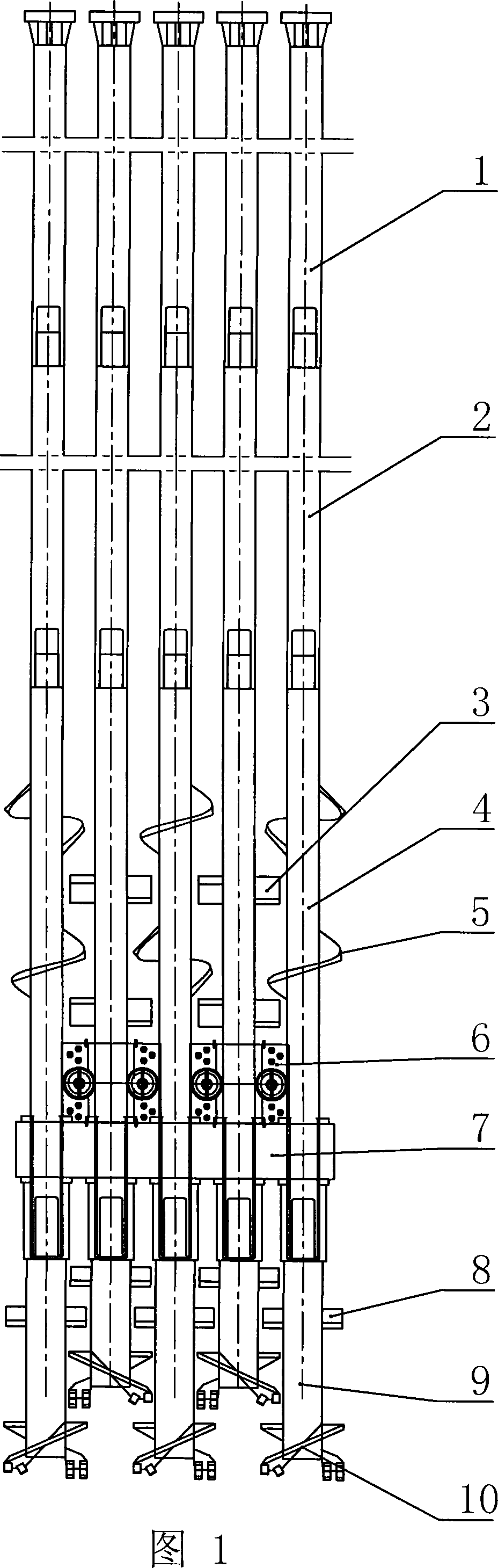

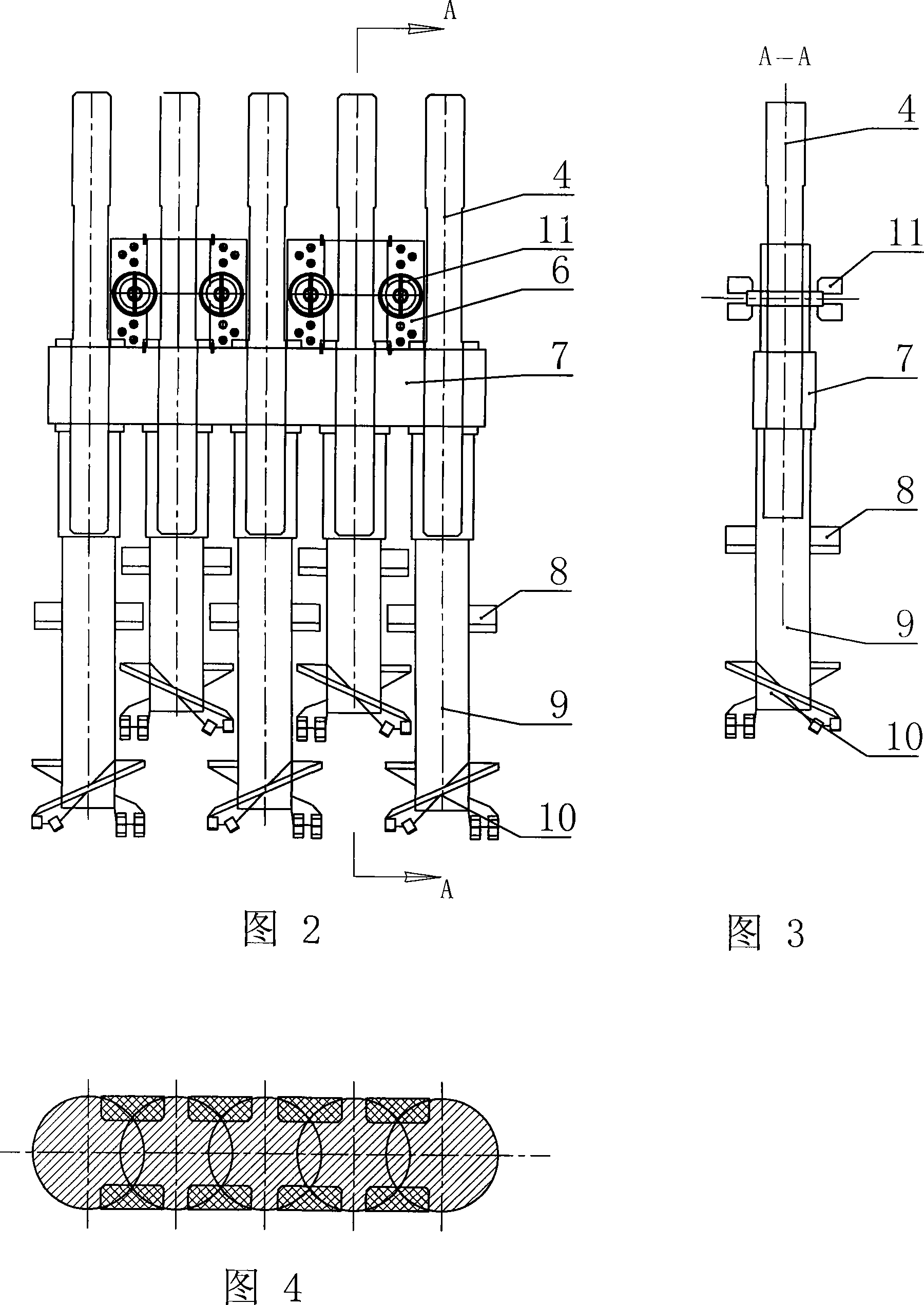

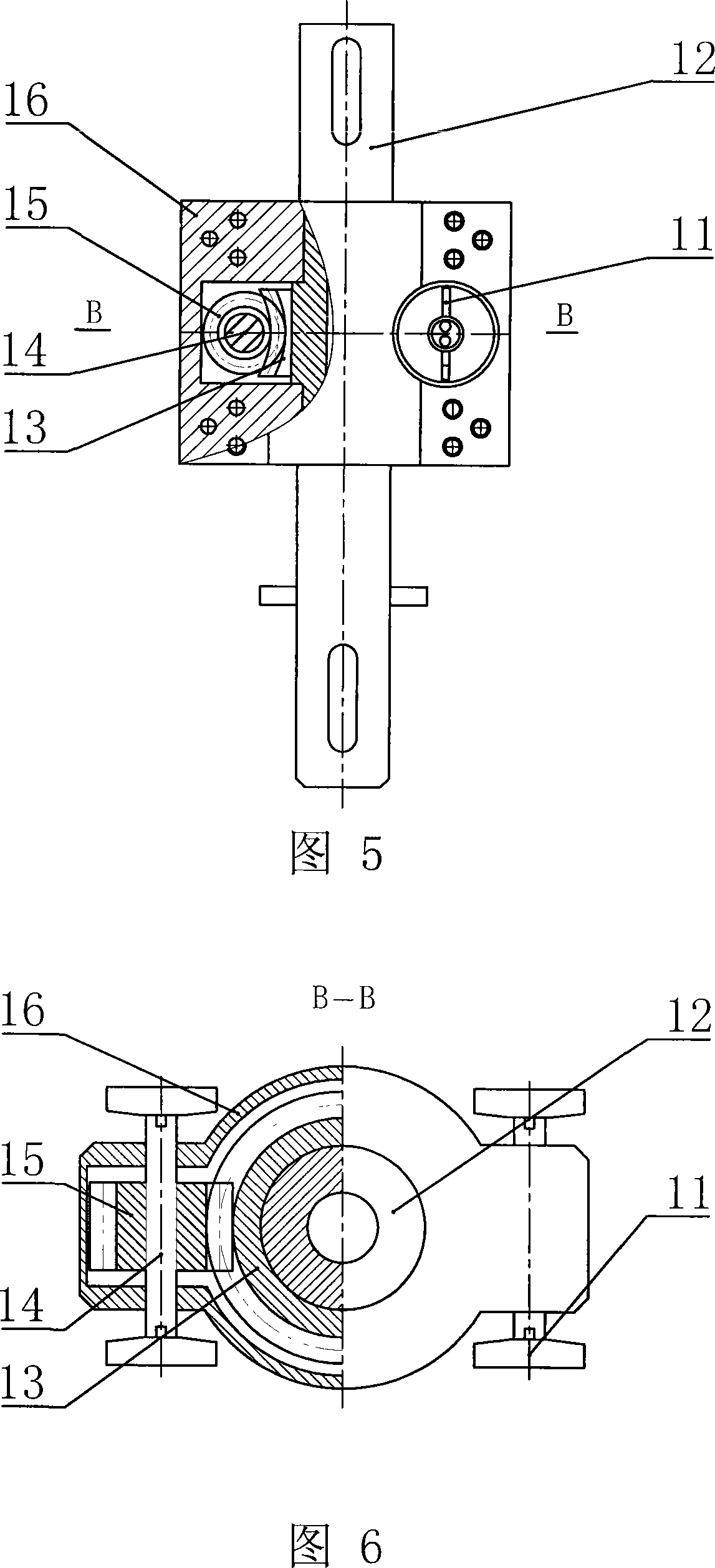

[0013] As shown in the figure, it is a multi-head equal-thickness deep-layer mixing drilling rig, including five groups of hollow drill rods arranged in parallel to each other. Each group of hollow drill rods is connected by upper drill rod 1, middle drill rod 2 and lower drill rod 4 from top to bottom. Composition, each lower drill rod 4 passes through the horizontally arranged cage 7 respectively, and the lower drill rod 4 on the upper part of the cage 7 is provided with a helical blade 5 and a stirring blade 3 along its axial direction, and the helical blade 5 and the agitating blade 3 can be set On the same lower drill rod 4, it can also be arranged on two adjacent lower drill rods 4 respectively, and the lower end of each lower drill rod 4 is equipped with a digging head, and the digging head is composed of a hollow digging rod 9, a twist drill bit 10 and a stirring blade 8 , the twist drill bit 10 is arranged on the lower end of the digging rod 9, the stirring blade 8 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com