Multilayer grating bearing cylinder and preparation method thereof

A load-bearing tube and grid tube technology, which is applied in the direction of attacking equipment, weight reduction, projectiles, etc., can solve the problems of overall buckling instability of the structure, increase in structural weight, and increased weight, and achieve high quality efficiency and buckling stability The effect of enhancing the performance and reducing the amount of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

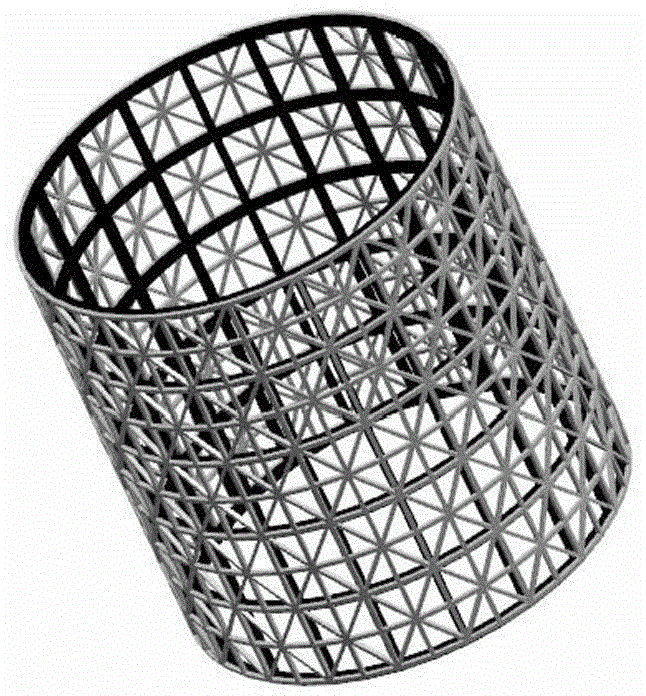

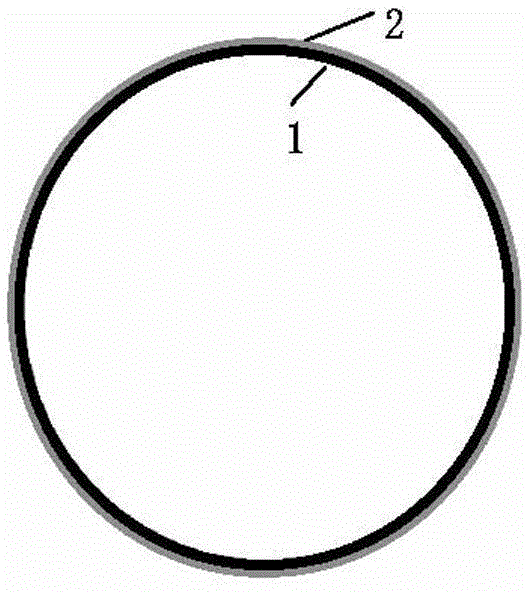

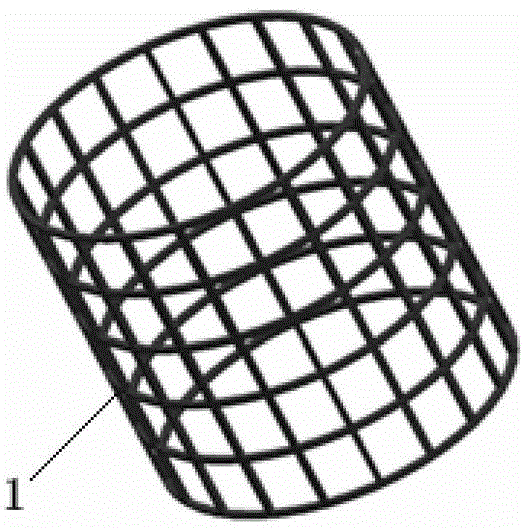

[0074] A kind of multi-layer grid load-bearing cylinder of the present invention, specifically double-layer grid load-bearing cylinder, such as Figure 1 ~ Figure 4 As shown, the multi-layer grid bearing cylinder is formed by nesting the inner grid cylinder 1 and the outer grid cylinder 2 . The grid of the inner grid cylinder 1 is sparse, and the grid of the outer grid cylinder 2 is relatively dense.

[0075] In this example, if image 3 and Figure 5 As shown, the unit grid configuration of the inner grid cylinder 1 is square. The inner grid tube 1 is composed of circumferential ribs and longitudinal ribs intersecting. In the cylindrical surface of the cylinder, the angle θ between the circumferential ribs and the circumference of the cylinder is 0°, and the angle between the longitudinal ribs and the circumference of the cylinder is 0°. θ is 90°. The inner grill tube 1 of the square grid has 6 circumferential ribs and 20 longitudinal ribs in total. Both are 5mm. The sp...

Embodiment 2

[0087] A kind of multi-layer grid load-bearing cylinder of the present invention is specifically a three-layer grid load-bearing cylinder, such as Figure 6 ~ Figure 10 As shown, the multi-layer grid bearing cylinder includes an inner grid cylinder 1 , a middle grid cylinder 3 and an outer grid cylinder 2 nested in sequence from the inside to the outside. The unit grid configurations of the three single-layer grid cylinders are similar, the grid structure of the inner grid cylinder 1 is the sparsest, the grid structure of the middle grid cylinder 3 is denser, and the grid structure of the outer grid cylinder 2 is relatively dense. most dense.

[0088] In this example, if Figure 8 As shown, the unit grid configuration of the inner grid cylinder 1 is rhombus. The inner grid tube 1 includes a grid, a top ring and a bottom ring. The grid is located between the top ring and the bottom ring. The grid is composed of the third spiral rib and the fourth spiral rib. for the circular...

Embodiment 3

[0103] A kind of multi-layer grid load-bearing cylinder of the present invention, specifically double-layer grid load-bearing cylinder, such as Figure 12 to Figure 15 As shown, the double-layer grid bearing cylinder is formed by nesting the inner grid cylinder 1 and the outer grid cylinder 2 . The grid of the inner grid cylinder 1 is sparse, and the grid of the outer grid cylinder 2 is relatively dense.

[0104] In this example, if Figure 14As shown, the unit grid configuration of the inner grid cylinder 1 is hexagonal. The inner grid cylinder 1 includes a grid, a top ring and a bottom ring. The grid is located between the top ring and the bottom ring. The grid is composed of discontinuous ring ribs, discontinuous third helical ribs and discontinuous fourth helical ribs. , both top and bottom rings are circumferential ribs. In the cylindrical surface of the cylinder, the angle θ between the discontinuous circumferential rib and the circumference of the cylinder is 0°, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com