Tank formation manufacturing technology for storage batteries

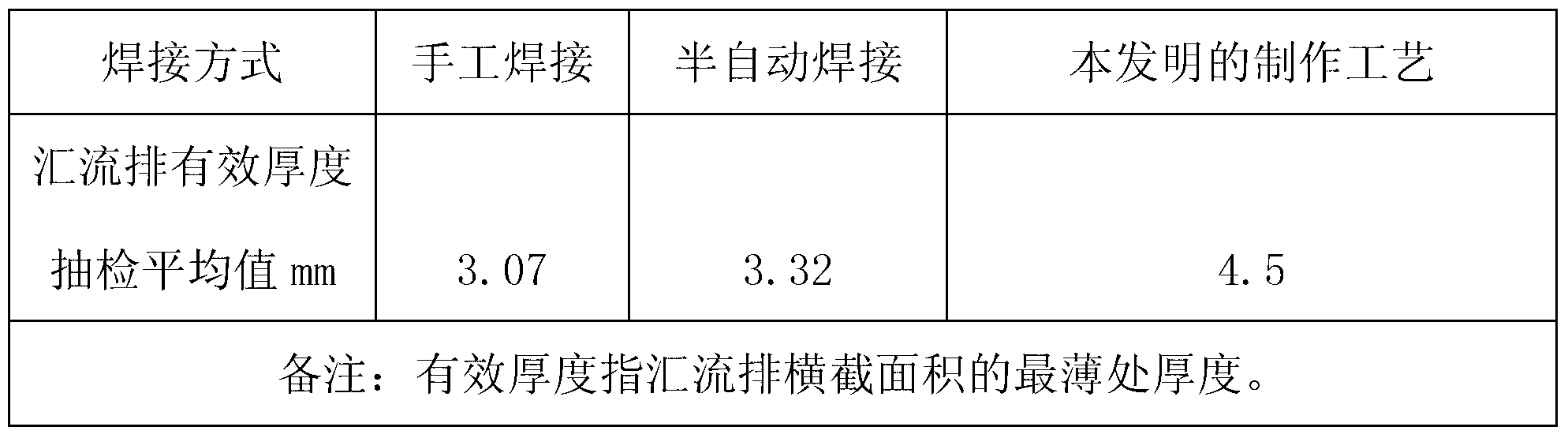

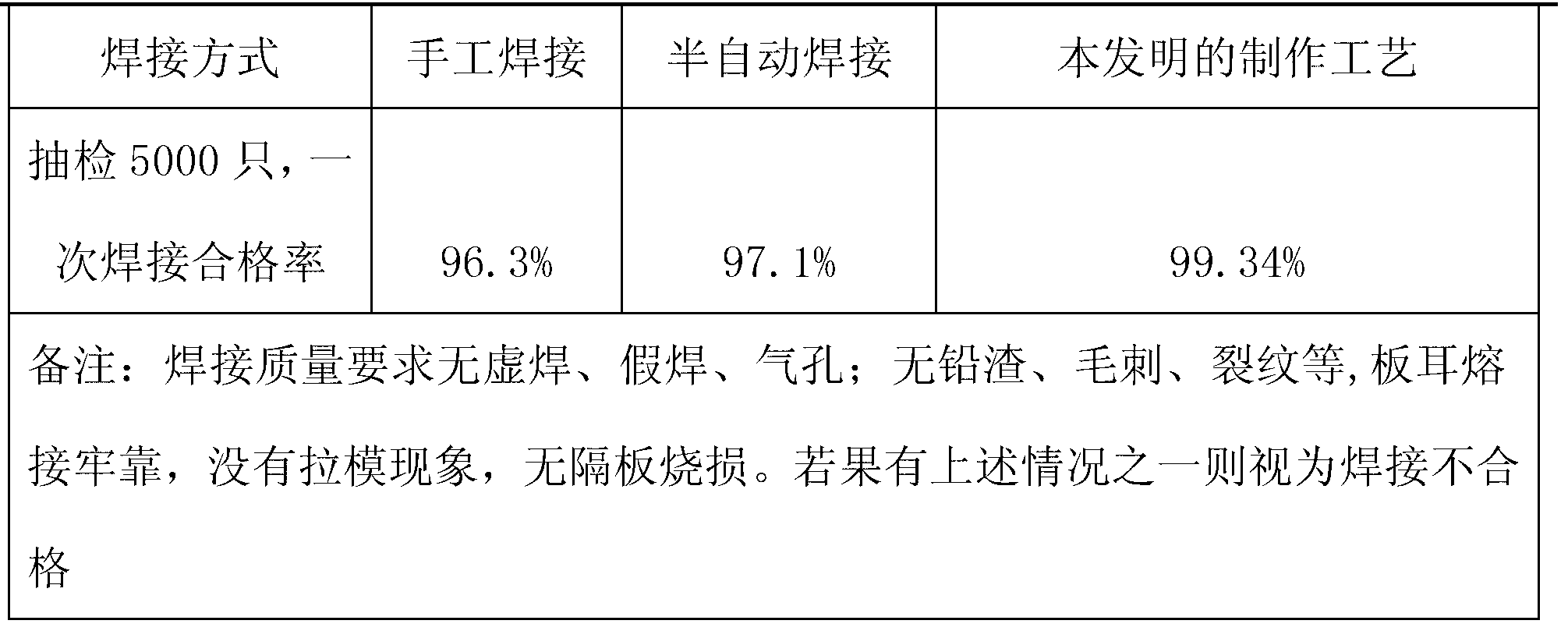

A production process and battery technology, which is applied in the field of externalized battery production technology, can solve the problems of false welding of tabs, high labor intensity, and holes, and achieve the effects of improving welding quality, increasing effective thickness, and improving corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] A production process of externalized storage battery, the process includes putting the pole group into the assembly box, arranging the tabs, cutting and brushing the tabs, dipping in flux, casting and welding, inspection, qualified transfer, and checking that the air source pressure is in the range of 0.45-0.7MPa Within, such as 0.45MPa or 0.5MPa or 0.6MPa or 0.7MPa can make the pneumatic parts of the casting and welding machine run smoothly, as follows.

[0024] Put the pole group into the assembly box: first check the quality of the packaged pole group and test the assembly pressure. The polarity of the adjacent electrode group conforms to the series sequence of the battery cells, and the polarity cannot be reversed.

[0025] Arranging the tabs: place the tab for correcting the tabs between the positive and negative tabs of the pole group, and use the tab shaping jig to correct the tabs of the pole group so that the tabs of the same row are on the same line to avoid t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com