Marine SCR urea solution spraying system and control method

A technology of solution injection and SCR reactor, which is applied in the direction of mechanical equipment, engine components, machines/engines, etc., and can solve the problems of insufficient reaction, waste, and failure to achieve results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below by means of the accompanying drawings.

[0016] The main reaction principle of the SCR reactor 11 is to vaporize the urea solution at high temperature and fully mix the exhaust gas in the mixer. The mixed gas is in full contact with the catalyst in the reactor. The gas reacts to generate water vapor and nitrogen to achieve the denitrification effect.

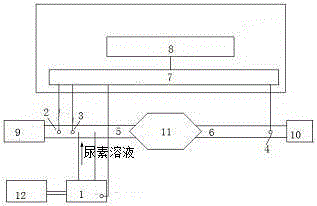

[0017] like figure 1 As shown, the present invention provides a marine SCR urea solution injection system, including a urea pump 1 and a flue, the flue is divided into a front flue 5 and a rear flue 6, and the urea pump 1 sprays urea into the front flue 5 Among them, the front flue 5 is provided with a flowmeter differential pressure transmitter 2 and a first NOx sensor 3, and the rear flue 6 is provided with a second NOx sensor 4, a urea pump 1, a flowmeter differential pressure transmitter 2, The first NOx sensor 3 and the second NOx sensor 4 are respectively ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com