Growth method for obtaining high aluminium component Al-Ga-N alloys by improving aluminium doping efficiency

A growth method and technology of aluminum gallium nitride, used in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., to achieve the effects of excellent quality, suppression of surface cracks, and excellent luminous performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

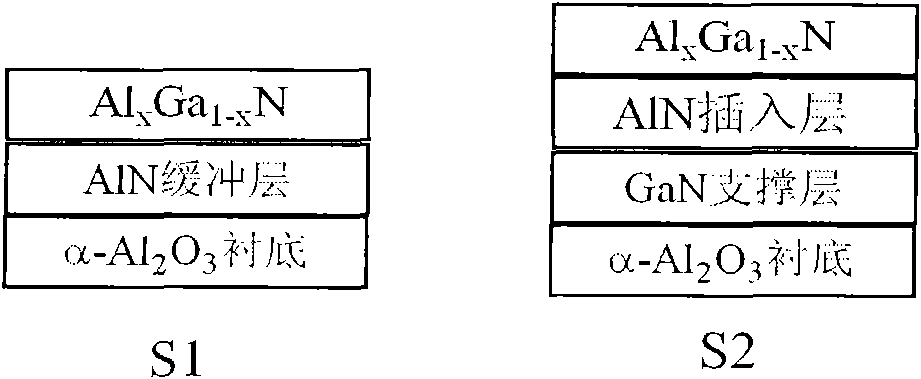

[0022] Technical solution of the present invention is to adopt MOCVD in α-Al 2 o 3 Epitaxial growth of AlGaN alloy thin films on substrates, using metal-organic sources TMAl and TMGa as group III sources, NH 3 As a Group V source, H2 As carrier gas:

[0023] Use AlN as the buffer layer, the growth temperature of the AlN buffer layer is 600 to 1000°C, and the growth thickness is from 10 to 100nm. After the growth of the AlN buffer layer is completed, the temperature of the reaction chamber is raised to 1100-1150°C to continue growing Al x Ga 1-x N alloy film layer;

[0024] Or use thick GaN as the support layer, first grow a layer of GaN on the substrate as the support layer, the thickness of the GaN support layer is 2-5 μm, the growth temperature is 1050 °C, and then set the temperature of the MOCVD reaction chamber to 700 to 1000 °C, Grow the AlN insertion layer with a thickness of 10-100nm. After the growth of the AlN insertion layer is completed, raise the temperature t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com