Cleansing device

A technology for cleaning devices and objects to be cleaned, applied to cleaning equipment, cleaning methods and utensils, refurbishing/cleaning record carriers, etc., capable of solving problems such as unstable CO2 generation and inability to independently control the temperature of nozzle 18

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

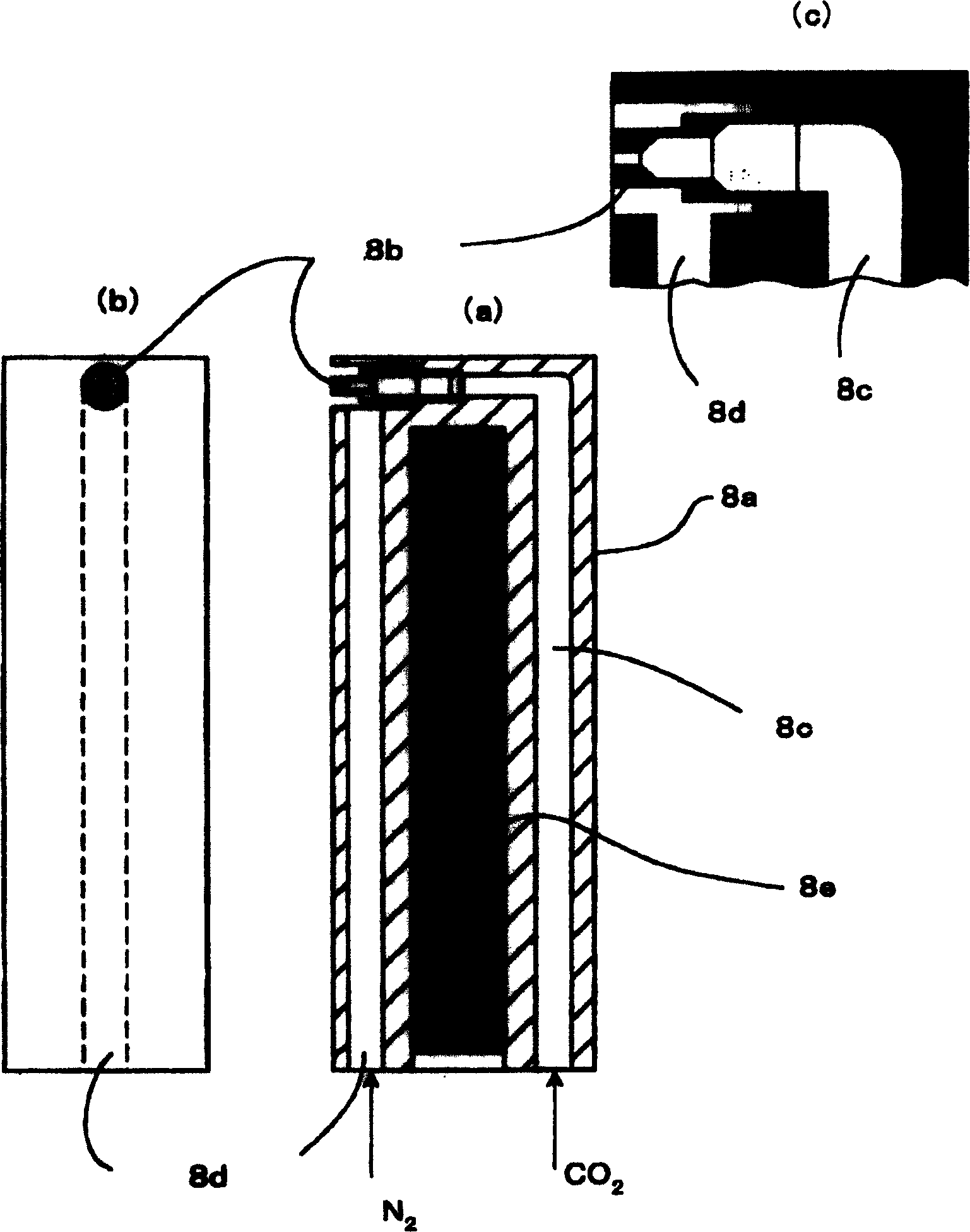

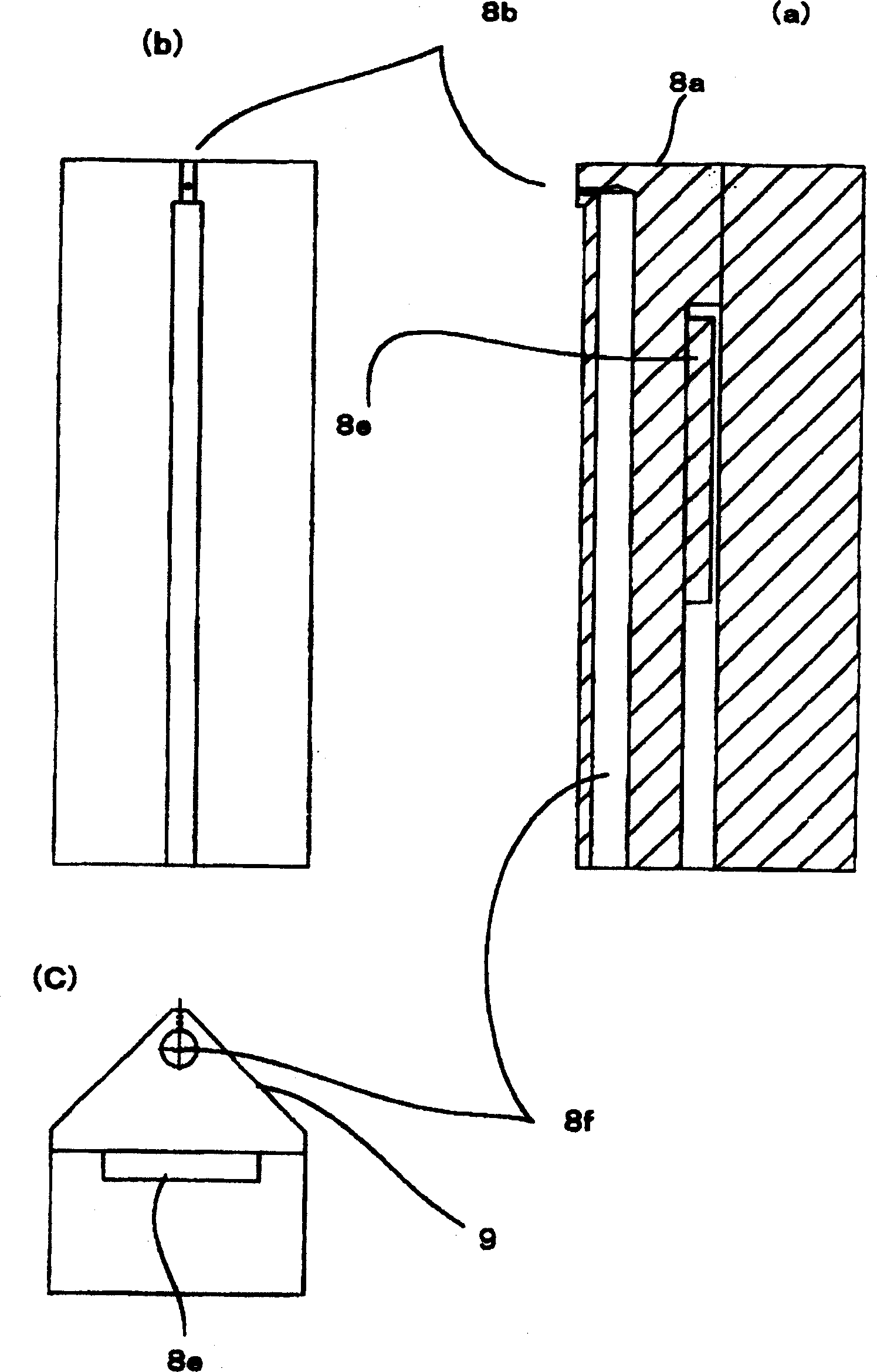

[0035] The present invention will be described in detail below with reference to the accompanying drawings.

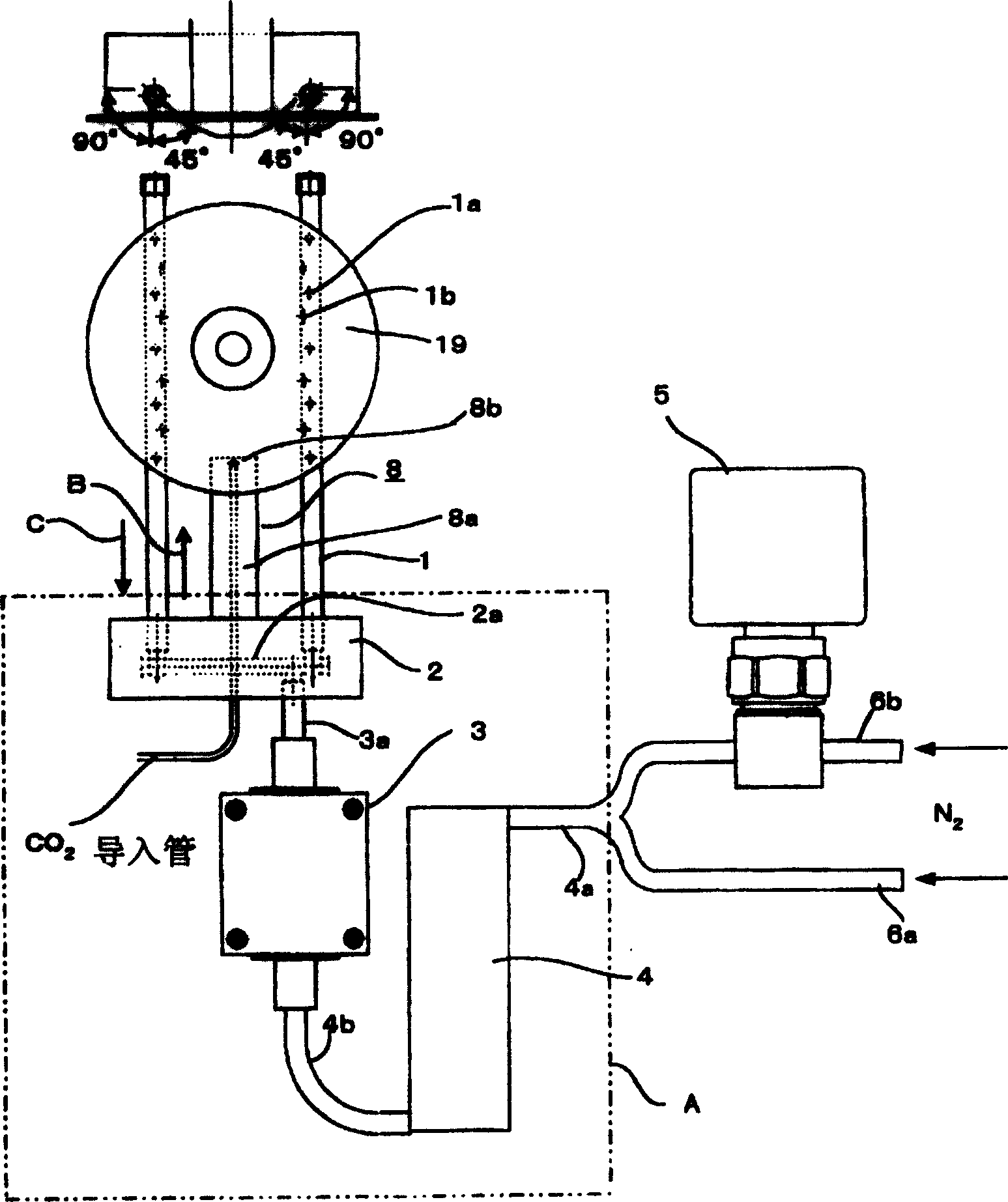

[0036] figure 1 It is a configuration diagram of main parts showing an example of an embodiment of the cleaning device of the present invention. In the figure, part A surrounded by double-dot dash line is the insulation room, which is omitted in the figure, and it uses heat insulating material to prevent heat exchange with the outside. A heater block 4, a filter 3 and a support member 2 are placed in the heat preservation chamber. In the figure, one of these pipes is disposed between the center and the peripheral edge of the object 19 to be cleaned. Since the main purpose is to prevent dew condensation on the object 19 to be cleaned, it is desirable to install four pipes on the front surface and the back surface. But at least one will do if it prevents condensation.

[0037] On the pipe 1, two series of holes 1a, 1b are formed in the length direction, these holes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com