Water spray type steam compressor

A steam compressor and water spray technology, which is applied in the direction of liquid variable volume machinery, mechanical equipment, engine functions, etc., can solve problems such as difficulty in grasping the state of wet steam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

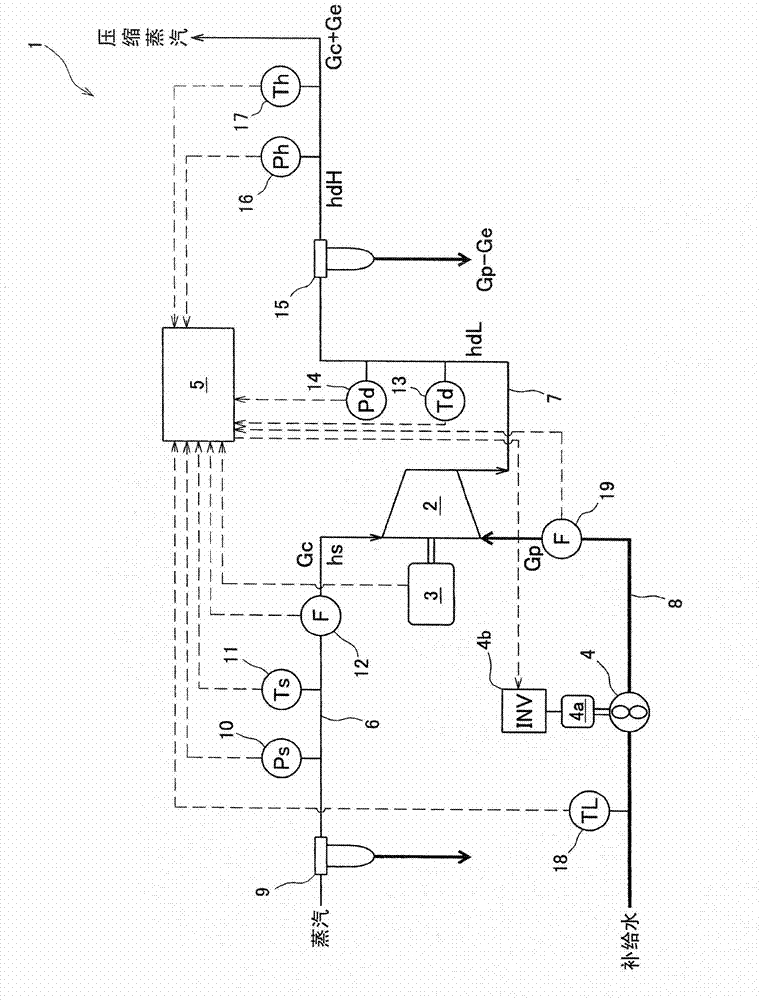

[0026] Hereinafter, modes for implementing the present invention will be described with reference to the drawings.

[0027] (Structure of water jet steam compressor)

[0028] Such as figure 1 As shown, a water jet steam compressor 1 includes a screw compressor 2 that compresses and discharges steam, a motor 3 that drives the screw compressor 2 , a water jet pump 4 , and a control unit 5 that controls the water jet pump 4 . The water jet pump 4 is driven by an electric motor 4a, and the rotational speed of the electric motor 4a is controlled by an inverter 4b. The water jet pump 4 corresponds to the water supply mechanism of the present invention. It should be noted that it may also be a rotary compressor, a scroll compressor, a Roots compressor, etc. instead of a screw compressor.

[0029] A suction pipe 6 and a discharge pipe 7 are connected to the screw compressor 2 . The suction pipe 6 is a path for supplying steam to be compressed to the screw compressor 2 , and the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com