Etching and cleaning device and method for OSP substrate

An etching equipment and etching technology, which is applied in the manufacture of electrical components, semiconductor/solid-state devices, circuits, etc., can solve the problems of inability to control the composition of chemical etching agents at any time, the inability to change the composition conveniently, and the low etching efficiency. Save packaging equipment and materials, excellent corrosion inhibition performance, good etching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer and clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0033] A specific embodiment of the present invention provides a method for etching and cleaning an OSP substrate before ball planting,

[0034] A kind of etching cleaning method of OSP substrate comprises:

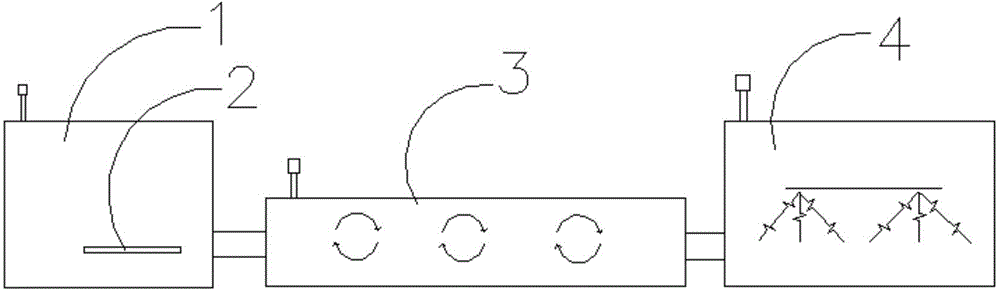

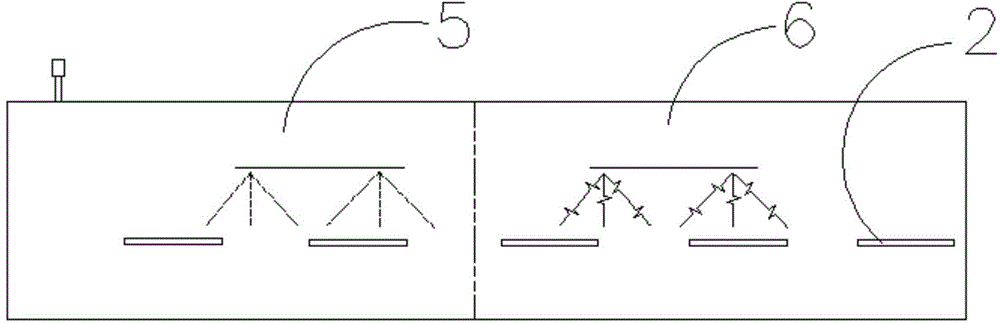

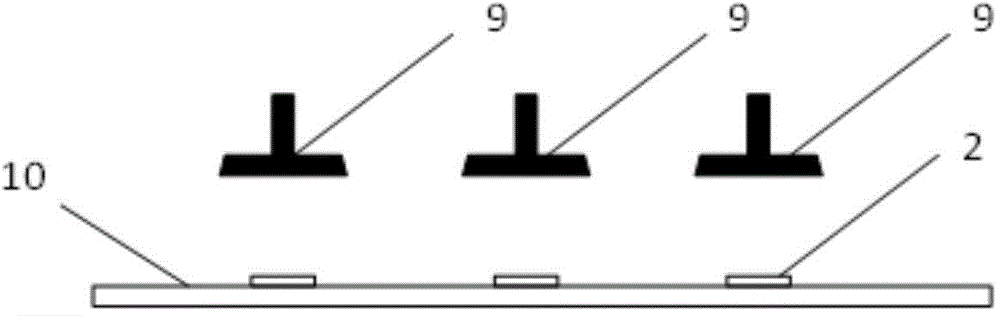

[0035] Such as figure 2 As shown, the first step: the chemicals are mixed in proportion and added to the cavity of the etching cleaning equipment;

[0036] The chemical agent, each component is calculated by weight percentage, and each component is H202 2-10%, H2SO4 4-20%, AGS2116 1-5%, AGS2115 10-50%, and the rest is pure water.

[0037]The ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com