Method for determining the rail pressure in a common rail system, and common rail injection system

A technology of injection system and rail pressure, which is applied in fuel injection control, electrical control, machine/engine, etc., and can solve the problems of keeping the quantity regulating valve open, unable to control the injection quantity, rail pressure rising pressure sensor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

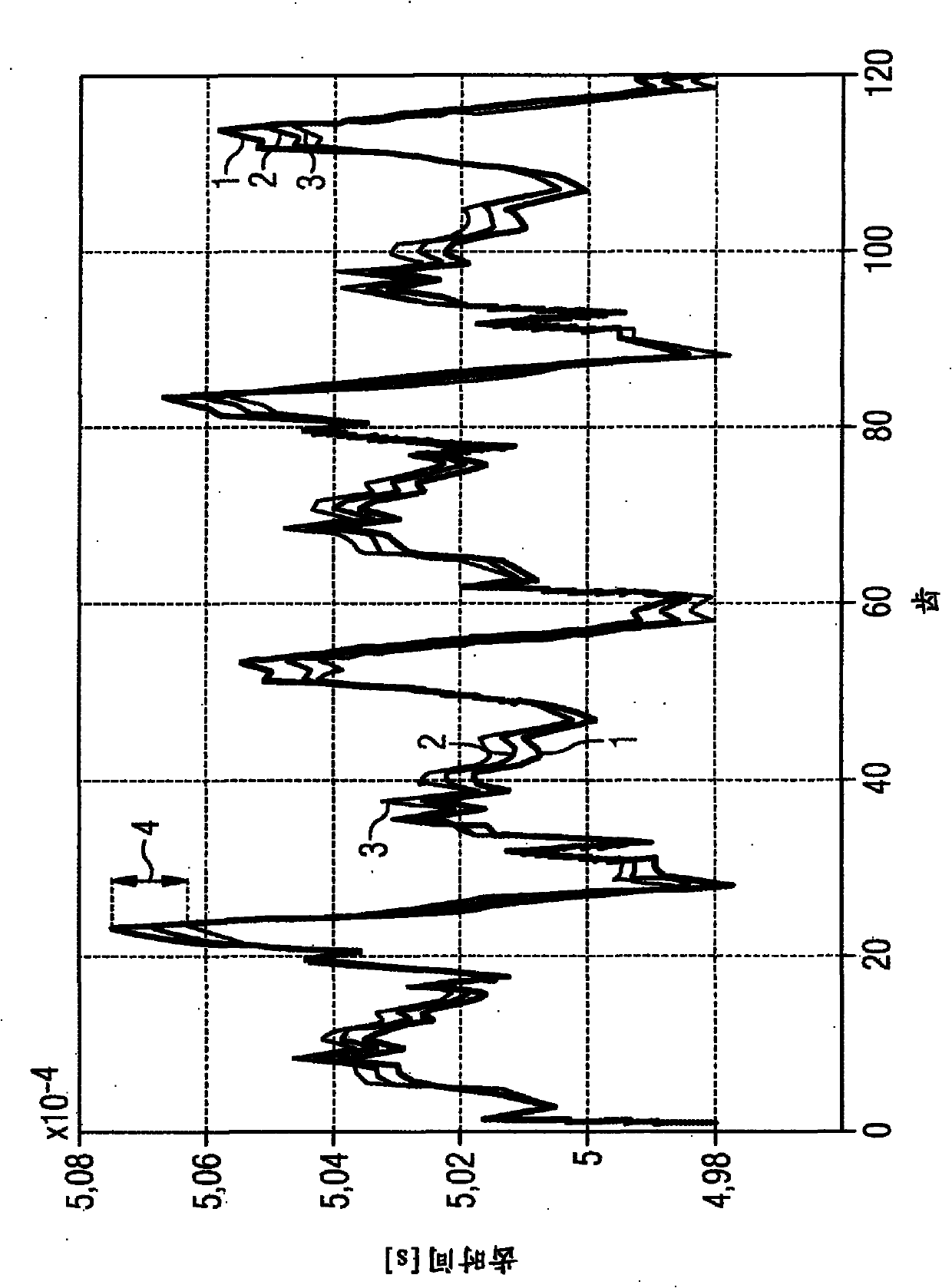

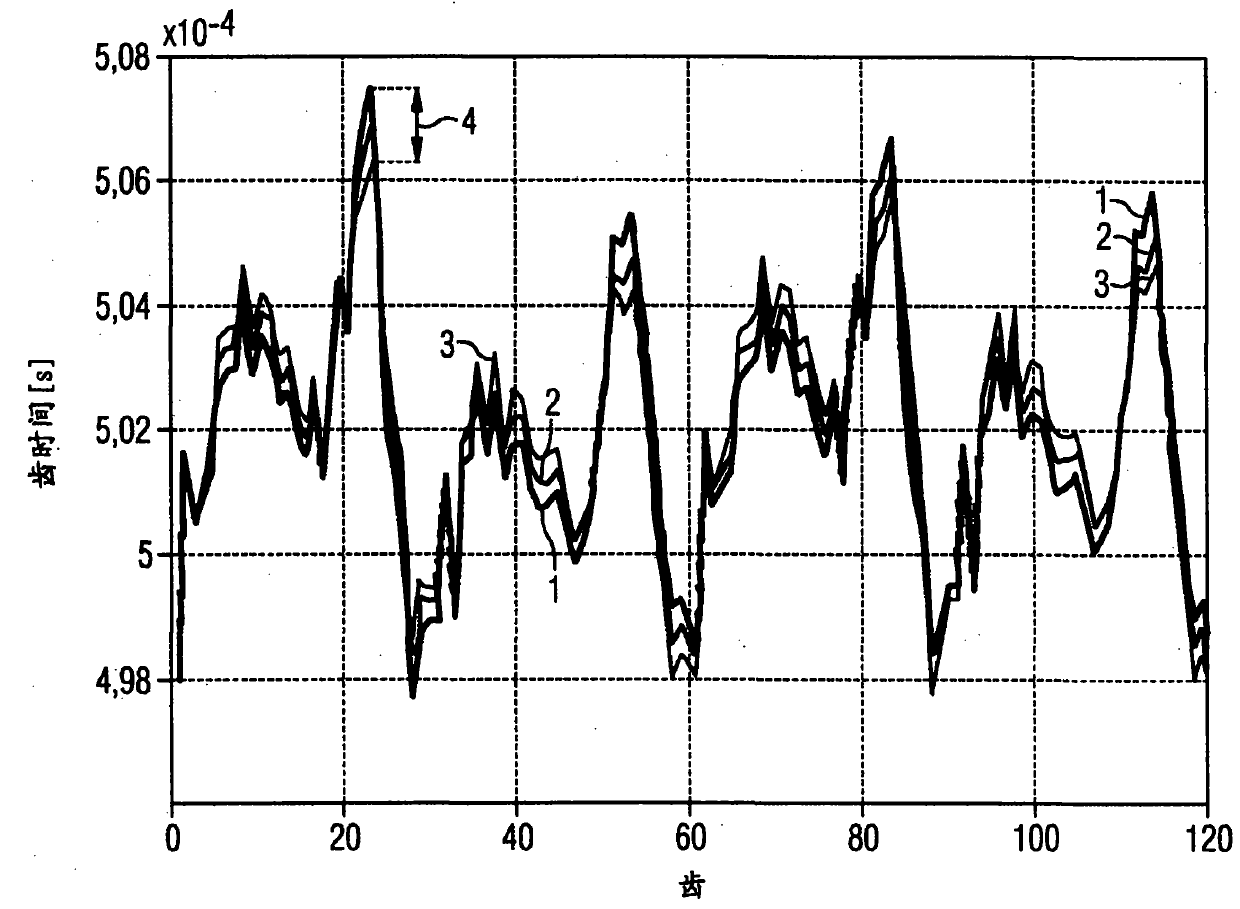

[0029] figure 1 For the inertia running phase of the internal combustion engine under three different rail pressures in the common rail fuel injection system of the internal combustion engine with 10 -4 The tooth time in seconds, where the intake pressure and average speed are the same values under these three different operating conditions. Along the X-axis are the four working strokes of a four-stroke engine. figure 1 It describes the absolute tooth time, that is, the time measured by the sensor when two adjacent teeth on the sensor wheel connected to the crankshaft pass by the sensor. The sensor wheel in the example shown has 60 teeth. In the four phases of a working cycle, 120 teeth pass the sensor. The curve labeled 1 shows the tooth time at an intake pressure of 160Mpa, curve 2 corresponds to 100Mpa, and curve 3 corresponds to 20Mpa. In the example shown, the two-piston high-pressure pump is coupled to the crankshaft with a transmission ratio of 1:1, so that the hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com