Improved shield master driving HBW grease injection device and control method thereof

A technology of oil injection and shield tunneling, which is applied in mining equipment, earth-moving drilling, engine components, etc., can solve the problems of oil waste, high sealing pressure, and outlet blockage, and achieve the effect of reducing consumption and construction cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

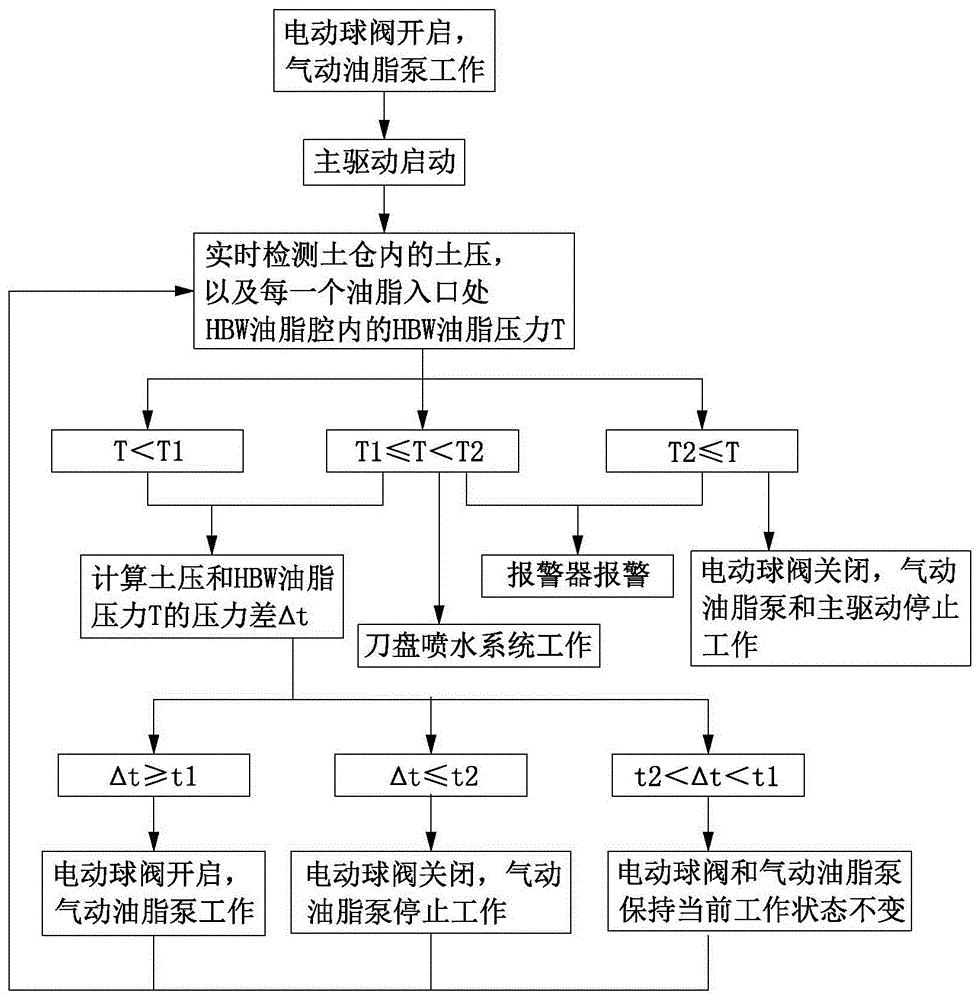

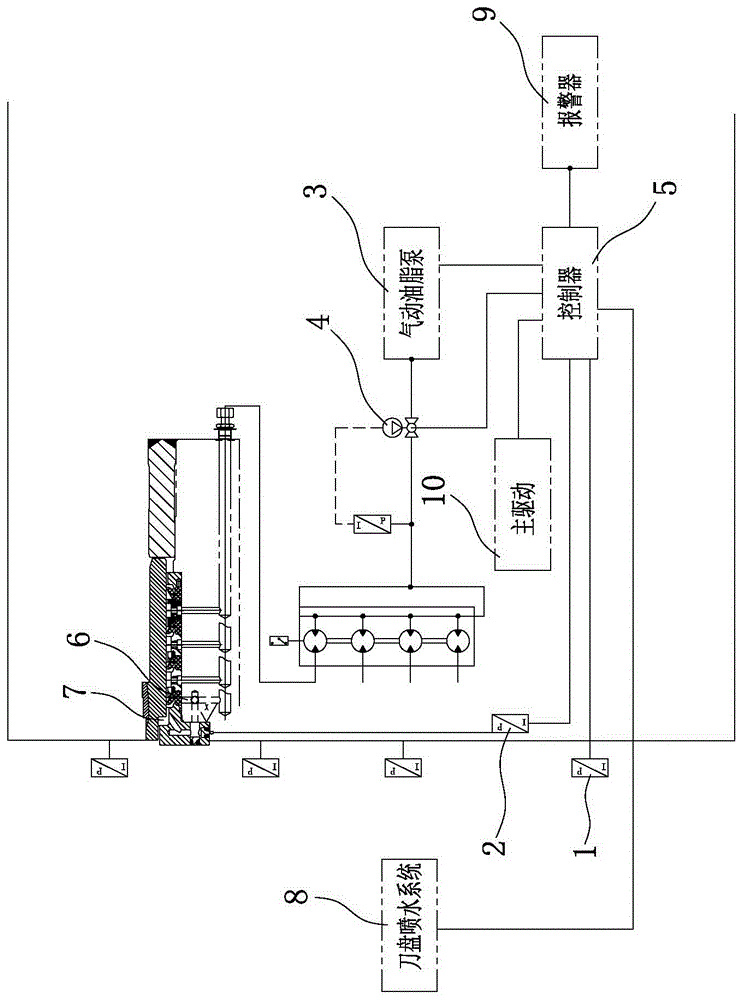

[0041] Such as figure 1 As shown, an improved shield main drive 10HBW grease injection device disclosed in the present invention includes a plurality of earth bin pressure sensors 1, a plurality of grease chamber pressure sensors 2, a pneumatic grease pump 3, an electric ball valve 4 and a controller 5.

[0042] A plurality of soil bin pressure sensors 1 are evenly distributed and installed in front of the shield shell and the housing of the main drive 10 for detecting the soil pressure in the soil bin. A plurality of grease chamber pressure sensors 2 are respectively installed in the HBW grease chamber 7 at each grease injection port 6 to detect the pressure of the HBW grease in the HBW grease chamber 7 . The pneumatic grease pump 3 is used to pump HBW grease to each grease injection port 6, and the electric ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com